Well, I finally got the neoprene in and the storm has left me with nothing better to do than start making the plates up and document it for all you thread stalkers.

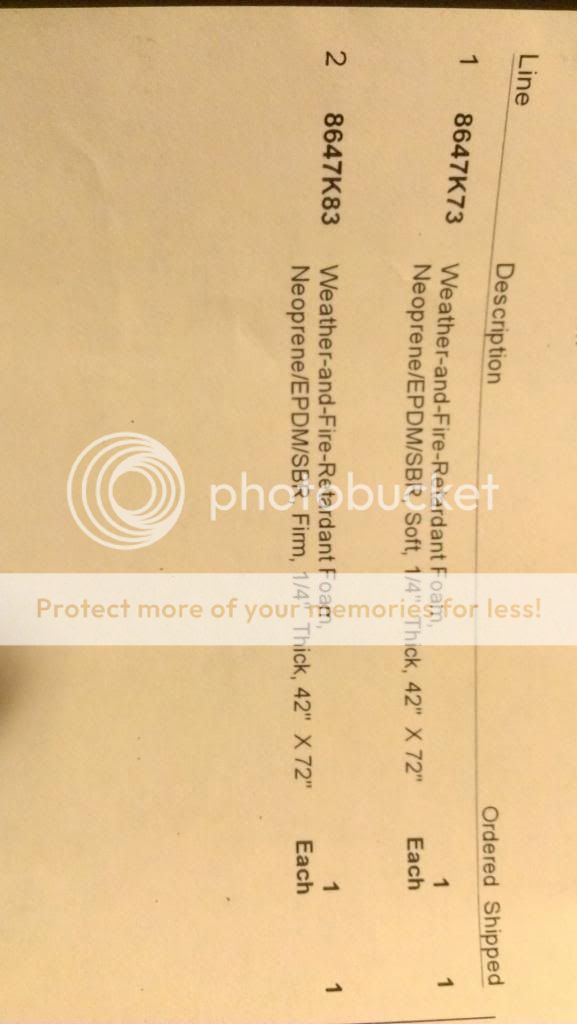

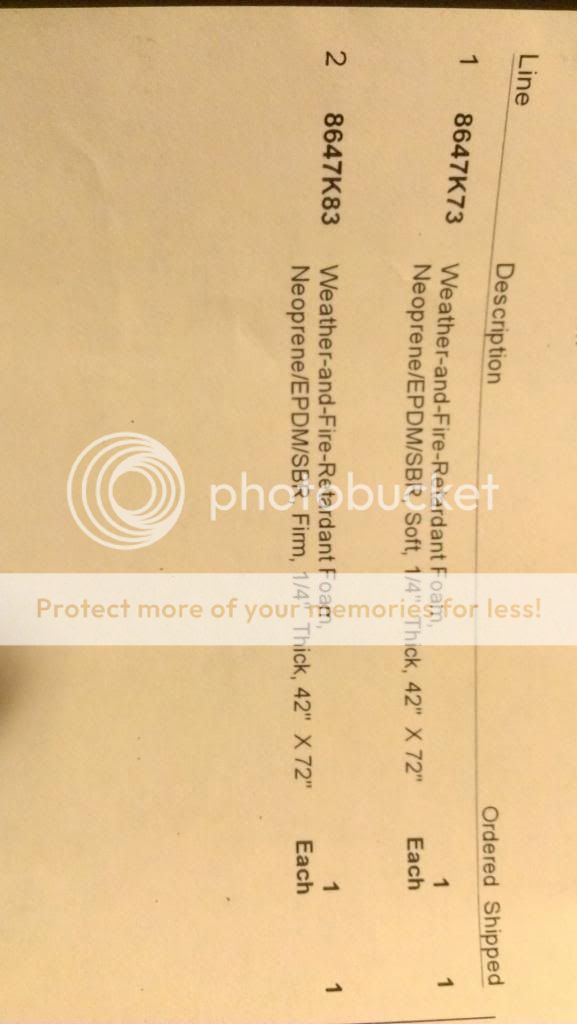

First, I give you the packing slip for the two rolls of Neoprene I bought from McMaster.com. One is "soft" and the other "firm". Each roll is roughly 42" x 72" and cost about $57. Each roll yields 21 layers, so enough for 10 plates. That's 21 plates total for both rolls.

You can buy it 42" widths and by the foot lengths at $12/ft. I would, however, suggest just pulling the specs from the McMaster website and use them to find it locally. I'm sure it can be had for less since McMaster does charge a premium. I only used them because I had a large order of other things I needed for work. Maybe, a bunch of you can start a "Plate Spall Build Party" and all pitch in for a roll or two and dive the cost.

After careful examination, I was unable to deduce any significant difference between the two. There is a slight "springyness" difference between the two, but it is low. I hit both sheets several times on a concrete floor with a hammer. The dents did not stay and both sprang back pretty quickly to original flatness. So, my thoughts for this test base on this and my previous results, are to just use the "soft" for the outer (second) layer and the "firm" for the inner first layer. My previous tests clearly showed the first, inner, layer to be taking the abuse. I'm hoping if there is any real difference between the two, the "tougher" one would be the one getting beat on.

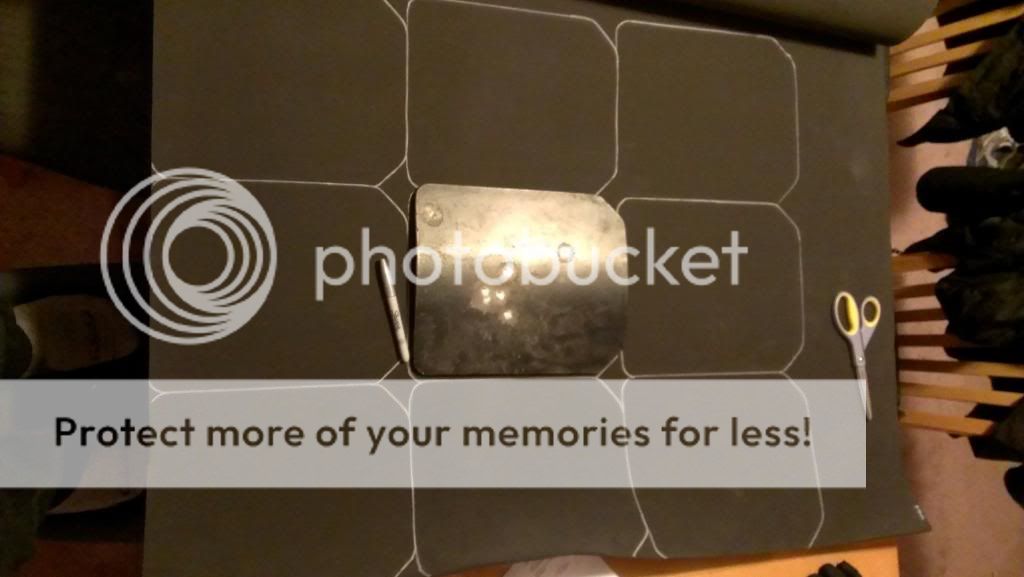

So it's time to break out the silver sharpie and start tracing. Note it's a SILVER sharpie, NOT a gray sharpie. The gray one didn't work, I tried.

The nest developing:

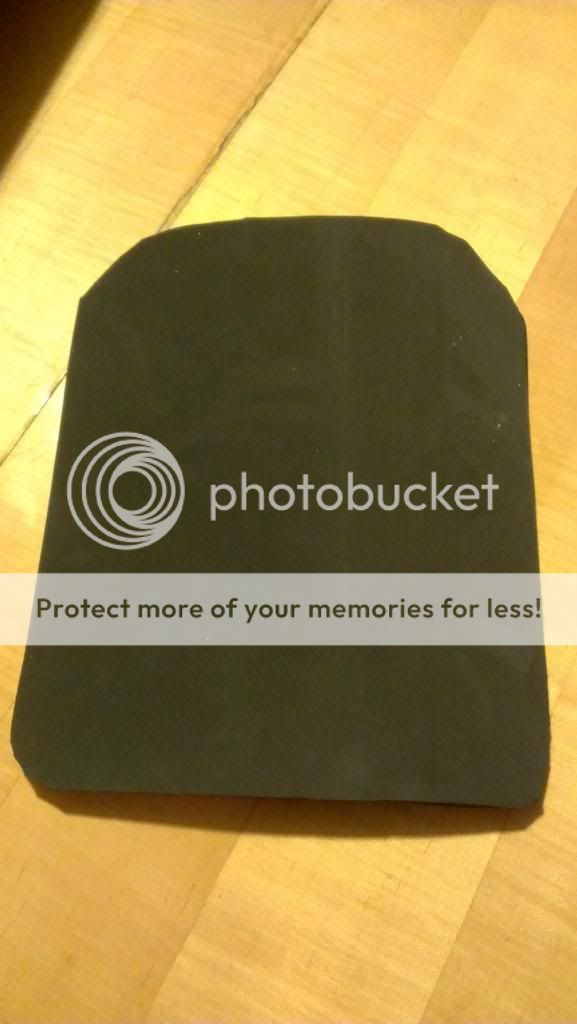

One cut out and shown offset on plate. I cut all 21 and the average weight was .138 lbs per piece:

Directly on top:

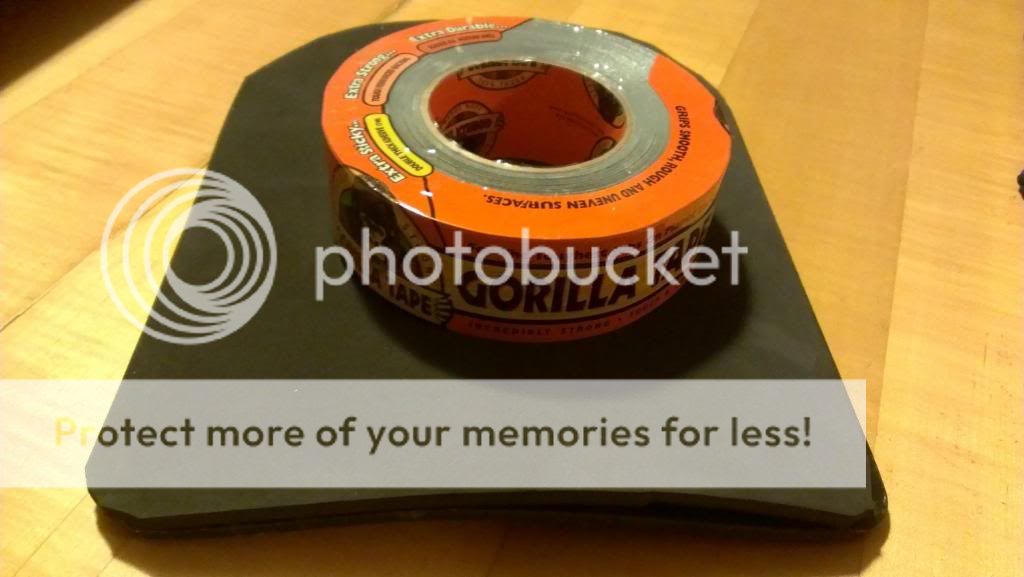

And now we break out Duct Tape's bigger, faster, stronger and better looking brother: Gorilla Tape

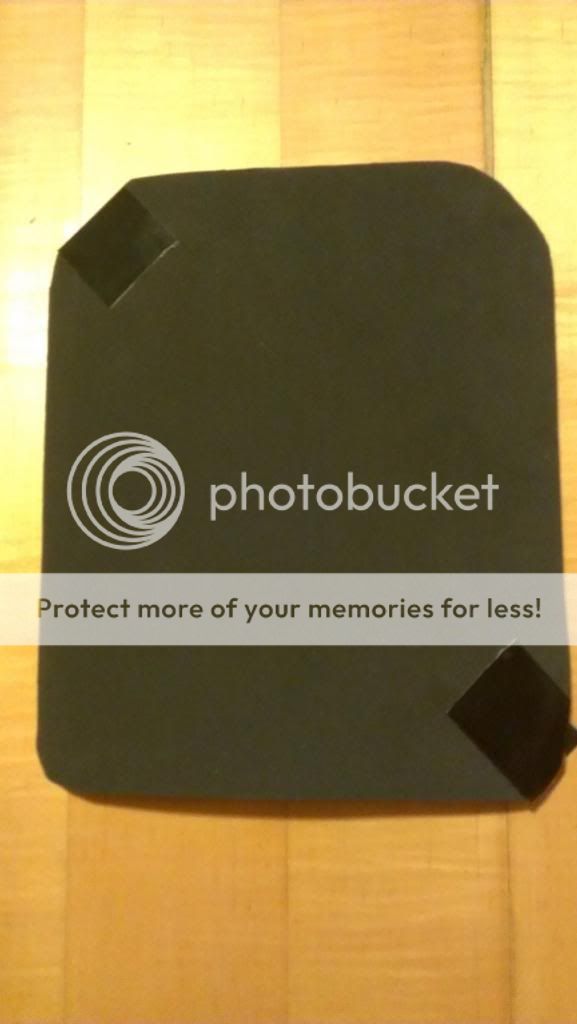

We start by taping the two diagonal corners to prevent weak spots:

Then we start taping. We're going at 45° for this layer //// and the second layer will be 45° the opposite way \\\\ giving us a bias ply construction. I'm hoping this will completely eliminate the seam bursts we saw in my original test:

And all done. The tape itself weighs .127lb for the whole layer. You might ask how I know this. Well, because I know one of you knit pickers would ask me, and I like being thorough I went the extra mile. I taped the first layer up entirely, removed the tape and weighed it separately, then re-taped it with new tape. Your welcome.

Now we apply the first contestant, Dupli-Color Bed Liner in two layers, 20 minutes apart after shaking the can for exactly 60 seconds each time per the instructions. Pic is the wet second layer:

And a pic of the can too:

I also will be spraying the back, over just the ends of the tape that wrap around. I need to let the top layer dry for at least an hour before I can flip it over. More to come along with final total weight added per plate when the two are all done and dry. Right now we're at .530 lbs per plate addition for two layers of foam and two layers of tape using data above.

Not sure the coating is going to add much, maybe another .1-.2lbs would be my guess. I'm not building up a thickness, really just using it as a tough glue to help the tape resist seam bursting along the edges. It may be plausible to only spray the outer edge as well and not the whole layers. I may add this to the list for a future test.

.. sort of serious..

.. sort of serious..

.. sort of serious..

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)