I hope this write up is adequate. I don't have the panache that Boris and Timber have for storytelling so have a few extra beers and pretend I'm entertaining.

Guidelines for my taking this on:

A) Cost is the driving factor. Must be super cheap as I have more than one carrier and they all have steel plates, thus all needing some solution.

B) Must be easy to accomplish, I don't want to spend more than 1/2 hour per plate to do this. I have a family and a life. I don't spend every waking hour down in my nuclear fallout shelter prepping.

C) Materials must hold up to long term use, abuse and storage. This means that the coating must tolerate varying temperatures, me throwing it around all the time, getting wet, resistant to salt/sweat, etc.

D) Result must fit in my carrier. This means controlling thickness to under 3/4" total including plate (.200"). Armor is already bulky.

E) Must take (2) shots of M855 at 50 yards. I've got to be reasonable here. I'm not out planning to be in Afghanistan getting pounded by AK rounds. I'd prefer to never get shot at all and never need to where this armor. If I was serious about having super armor I'd try to acquire dragon skin, not be out here messing around with steel surplus plates. M855 at least gives you the steel core bouncing around, which shout increase the damage of the spall over lead/copper. I base this on no research whatsoever. YMMV. I limit the test to two shots because if I get hit more than once someone has a bead on me and I'm about to get hit with shots three, four, five, etc and odds are one of them is going to hit me in a place other than my plate so spall is the least of my worries. I'm thinking more of this situation, minus the uparmored humvee to hide behind. I don't have one of those...yet:

Explanation and Setup:

I scrounged around my garage, basement, shed etc for materials. Things like rigid foams, cardboard, etc were immediately dismissed due to inability to survive abuse. I came up with neoprene from a floor mat (yes like the one you wipe your feet on) and some old jeans I had in a rag bin. The jeans are generic brands, not heavy duty Levi/Carhart/etc. Both of these materials are cheap, easy to cut/form to plates and light, thus not adding a lot of overall weight.

Now I needed someway to attach the padding to the plates. I again wanted something I would always have on hand. Ideally it would not be permanent so repairs could be made. Enter our favorite friend Gorilla Tape. Way better than duct tape and I have a shit ton of it. Easy to apply, tough, cheap and forms well to plates.

Three experiments:

1) Base Case - Bare Plate.

2) Neoprene Indoor Floor Mat - (2) Layers from Target (as in the store) that cost me a mind blowing $7 and is about .200" thick. One door mat will give you three layers.

3) Jeans - (10) layers (again these are thin crappy jeans) made from the legs.

Procedure:

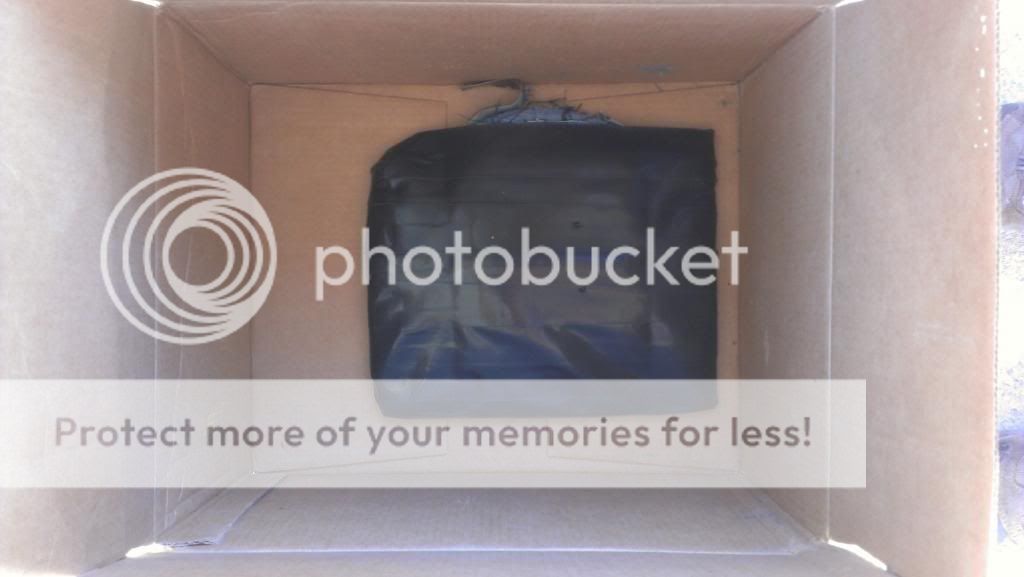

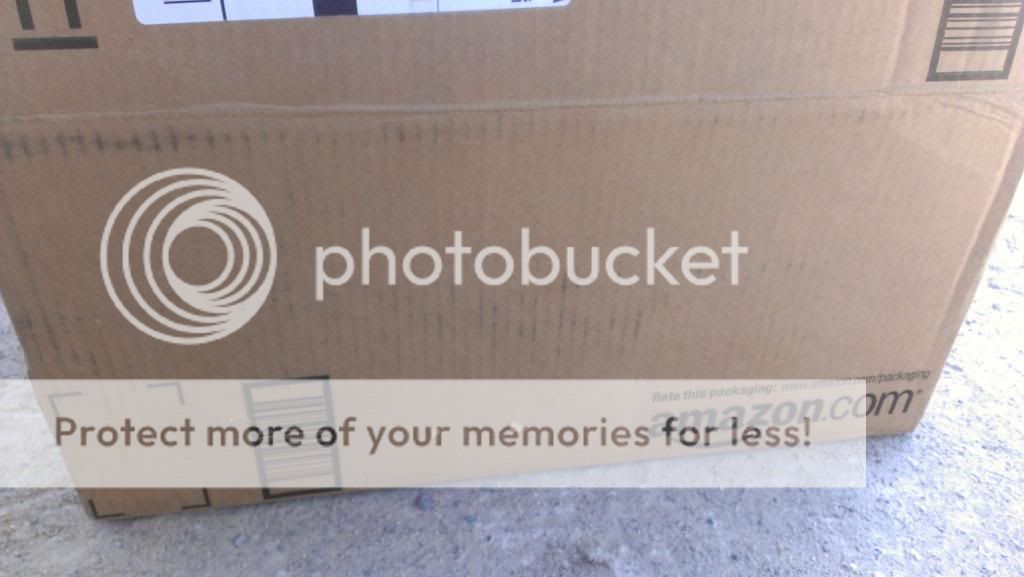

Again being a cheap bastard I need some way to "catch" the spall and rate it's danger. Some youtube videos show thin metal shrouds. I am more than capable of duplicating this, but the results I don't think would be easily understood by everyone reading the review here once I started yacking about gauge thickness etc. So I needed to find something everyone was familiar with that would somehow illustrate the spall's "danger." Enter the common cardboard box. Simple, effective. If the spall punches through the box it's fairly certain it can draw blood. If it doesn't I think we can be reasonably deduce no harm will come.

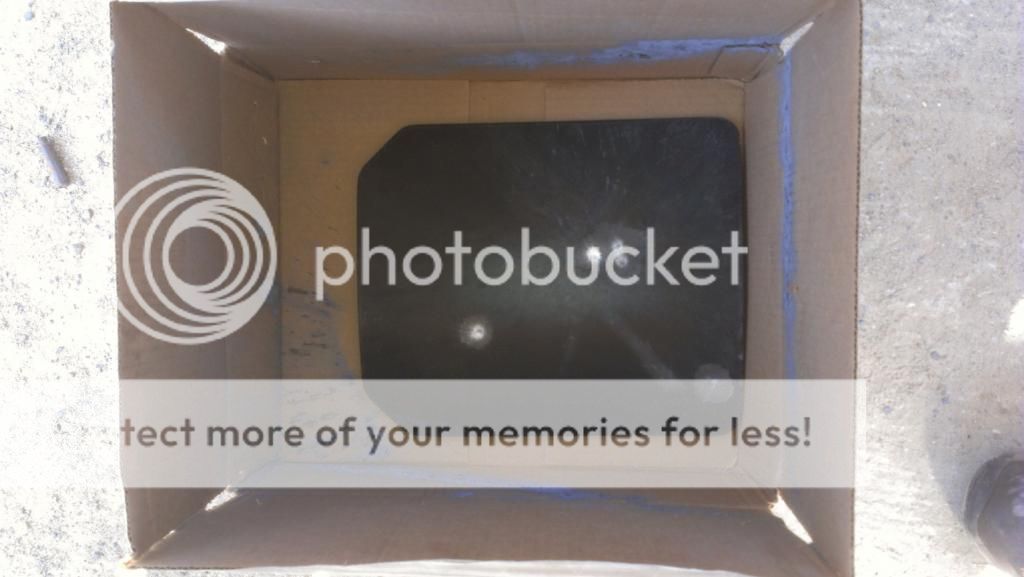

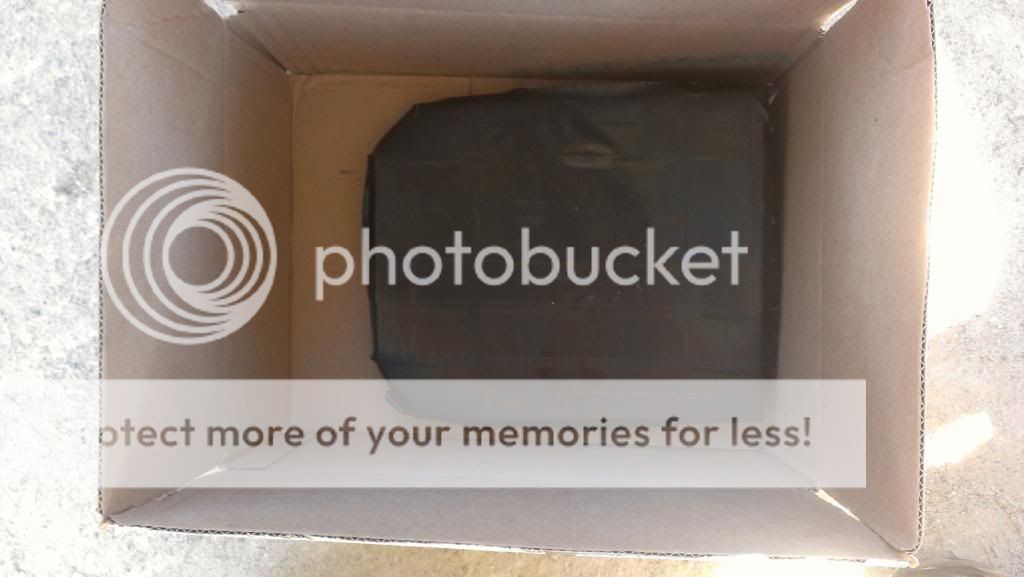

So each test will be conducted with the plate inside its own box. The plate will be free standing with a slight upward tilt giving the worst case, angled at your head. Plates with covering materials shall be held together with one layer of Gorilla Tape. Two rounds of ATI 62gr M855 will be fired at 50 yards. Results of each will be documented.

Results:

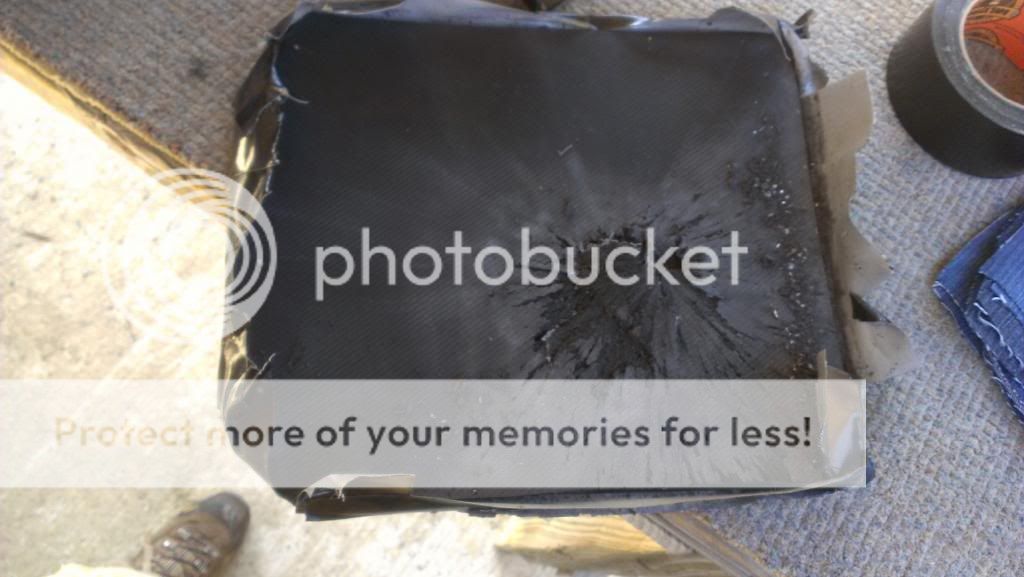

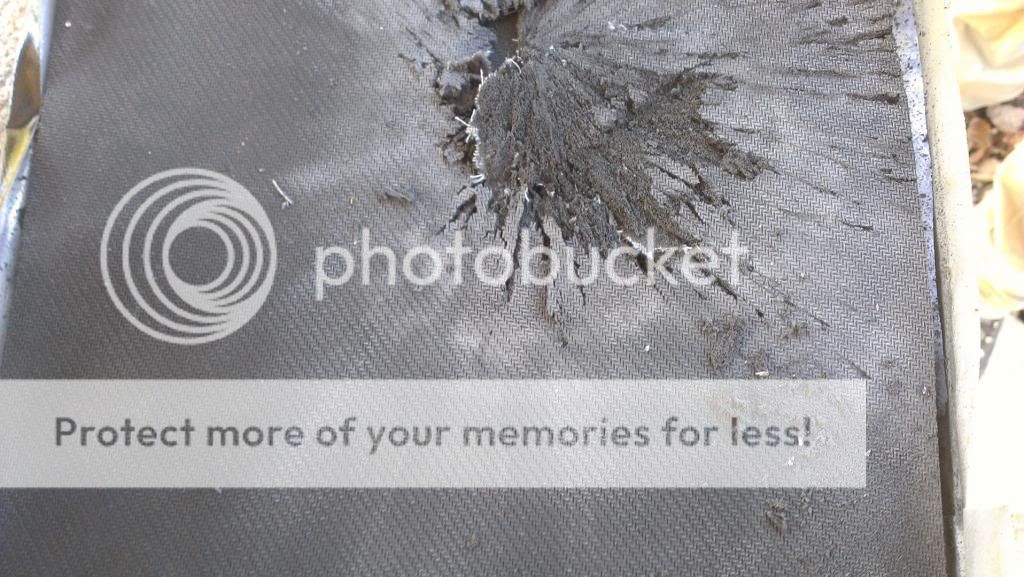

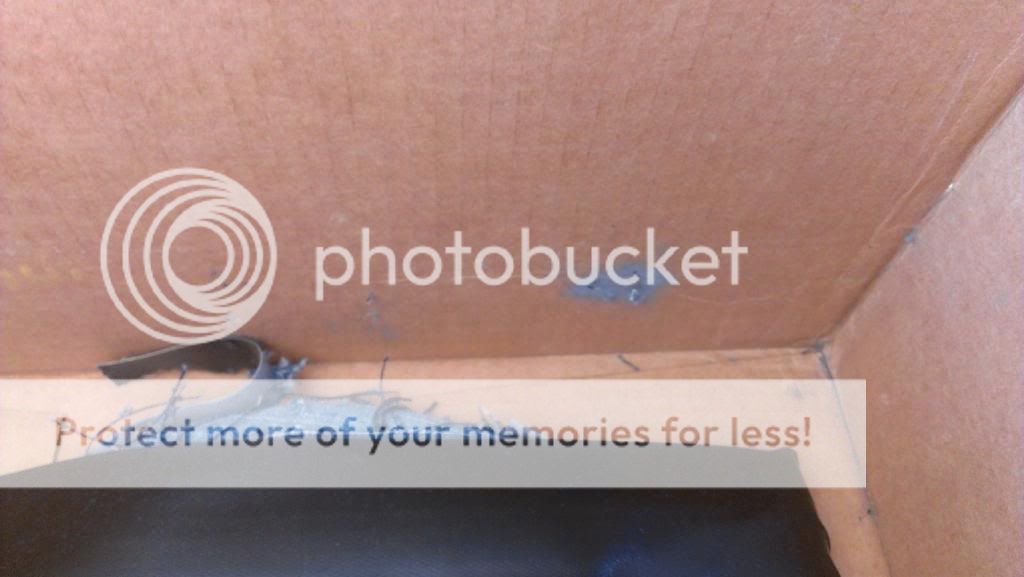

Let's start with the baseline case, bare plate. The results here were truly eye opening and frightening. Obviously this test ignore that you will have at least one layer of nylon (the carrier), but I think it serves nonetheless as a good place to start. Here in these pics you can clearly see the terrifying truth of what we're up against. I literally winced when I walked up to see the damage. I was not expecting this much damage:

I have to admit I was seriously doubting my cheap ass DIY solutions were going to help at all after this initial test, but things were about to take a nice turn. Next test was Neoprene with one layer of Gorilla Tape. The result turned the confidence tide towards the possibility something could be done:

Only one spall spot! Note the tape separation along the length of the strip. More about this later.

Bullet impact holes:

First side, note three tiny holes on right

Second side with spall spot

Side three, nothing!

Side four, nothing!

Here's a few pics of the cover removed. Note the shrapnel and how many tiny pieces there are.

Most damage taken by bottom layer:

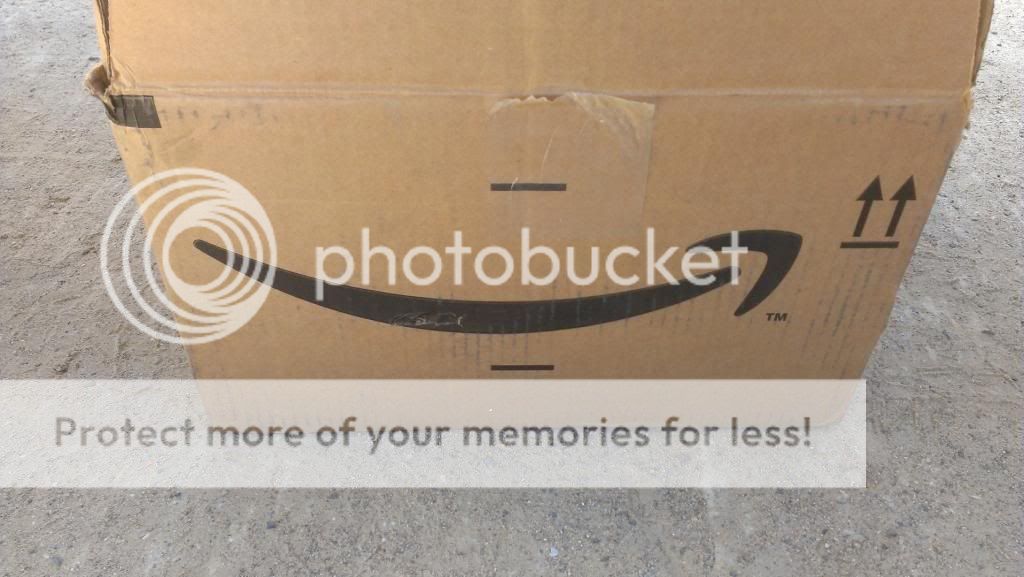

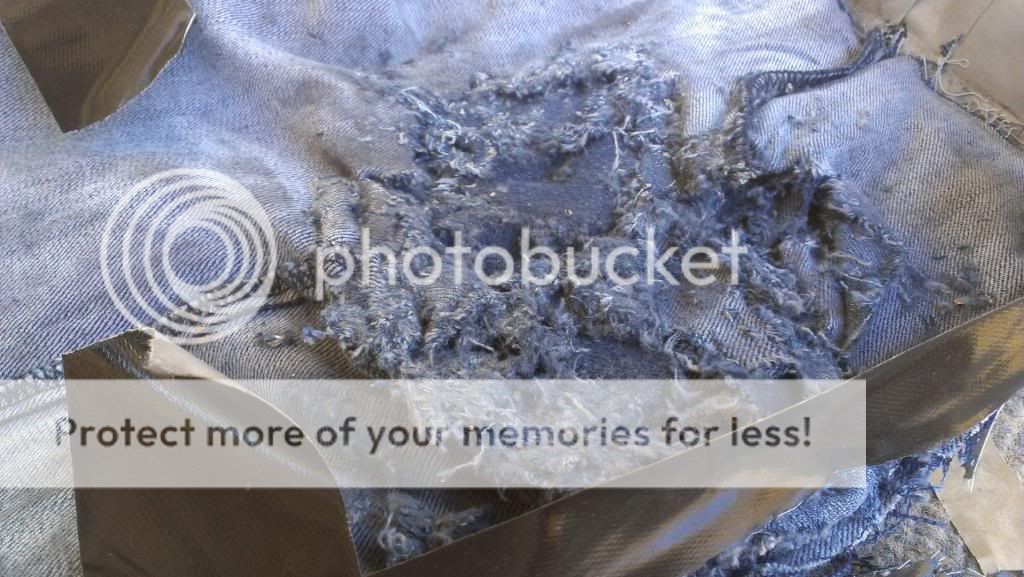

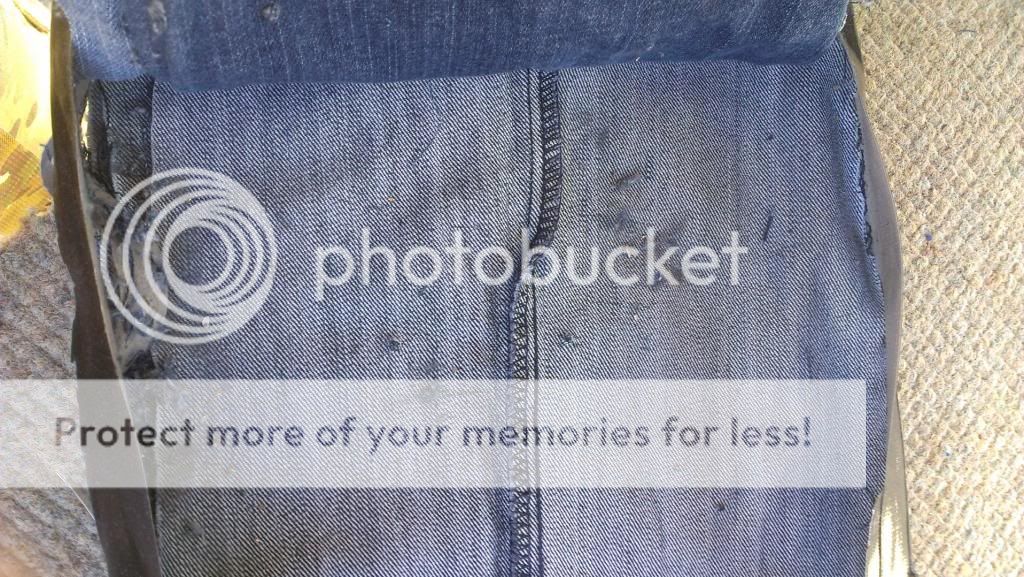

Moving on to the third test with the (10) layers of jeans. Layers were created by cutting the leg off jeans, slicing up the seam, then cutting in half. So each pair of jeans yielded (4) layers. Again one layer of Gorilla Tape applied.

Top view. Again note the tape separation along the length.

Closeup of blowout and small spall mark.

Impacts pointed out.

Box side one. Small gash on Amazon logo was present before test. No spall!!

Box side two. Shows two small spall marks. The pieces were still stuck in cardboard! No full penetration! Sucess!!!!!

Box side three. No spall.

Bow side four. See a trend? No spall!!

Cover removed. Note the decimation of the bottom layers. There was spall found between all layers, but only the bottom 4 of 10 were destroyed. The rest had only tiny holes and I would consider them reusable.

Between layers 5 and 6 (layer 1 being closest to plate)

Between Layers 6 and 7:

Plate after all shots fired. Lower left shot is from when I first got the plate. I shoot at every steel plate before it goes in a carrier. I will still be reusing this plate in a carrier. It is not a spare.

Lessons Learned and Next Steps:

Needless to say I'm very happy with the results here. After seeing the uncoated plate test I think its clear I've made pregress. Both test materials kept the plate relatively thin, less than a ceramic and added no more than 1/3-1/2lb per plate. I consider that weight negligible. We're talking about a carrier with steel plates and multiple loaded 30rd mags. Not exactly featherweight. The main concern I have now that needs to be addressed is the blowouts shown in both neoprene and jean tests. The blowout along with my shots be roughly centered on the plate leaves a little to be desired for closer to the edge hits.

I believe these can be remedied by simply using 2 layers of Gorilla tape 90° apart. I will be testing this in my next outing along with 3 layers of tape (one verticle and two at 45°). Another option is to use bed liner as shown in other youtube and forum tests. I'm thinking about using one layer of gorilla tape and then using a spray can of bedliner to cover it. Then I can compare the double and triple layer tape to it and see which avenue is better. I don't know the cost of the bed liner cans yet or how many plates I can coat with each can. This will be a deciding factor as I still want to keep this cheap. As of right now the best results, Jeans, cost me only the gorilla tape to make as I have tons of old jeans in my rag bins. I may retry the neoprene again with multi-layered tape in a second outing as well if I can remember to pick up another mat.

I hope this was helpful. If anyone else has any further ideas feel free to post them up and I'll see what I can do to try them out. I'll add at this point there is no way I'd waste the money on Kevlar. The cost is real high and I'm honestly not seeing any proof out there that it will be more effective than my DIY solutions have proven to be here. Again if I had cash and wanted to have highend protection I'd just buy premade sleeves. That is not the point of my experiments here.

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif)

![Grin [grin] [grin]](/xen/styles/default/xenforo/smilies.vb/041.gif)

![Machine Gun [mg] [mg]](/xen/styles/default/xenforo/smilies.vb/036.gif)