Most use "Elmer's Purple School Glue", that appears to be Scotch's equivalent?Is this glue what I need for the glass bed?

Works great for PLA and PETG. Advanced filaments, like ABS & Nylon, may require more advanced adhesives.

Last edited:

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

Most use "Elmer's Purple School Glue", that appears to be Scotch's equivalent?Is this glue what I need for the glass bed?

Pla is all I am toying with for now. We are just printing things for my boy. Learning on the go is a real eye opener.Most use "Elmer's Purple School Glue", that appears to be Scotch's equivalent?

Works great for PLA and PETG. Advanced filaments, like ABS & Nylon, may require more advanced adhesrives.

Yes but you shouldn't need it for PLA.I saw a video where the print hangs down which is interesting. I am not dumping a lot of noney into this but even the little stuff adds up fast.

Is this glue what I need for the glass bed?

I plan on printing a 50% skull with the pla in use now then on to other things with a different color.

I saw a video where the print hangs down which is interesting. I am not dumping a lot of noney into this but even the little stuff adds up fast.

Is this glue what I need for the glass bed?

The glass bed on my old Robo3D needed glue for everything. I used Aquanet Super Hold spray, but glue stick should work fine. Both are PVA glues.Yes but you shouldn't need it for PLA.

If pla is coming off the bed at 60°C then one or more of the following is going on:

1 - not enough first layer squish: adjust z offset

2 - build plate is dirty: good scrub in the sink followed by a wiped down with 90%+ isopropyl alcohol.

3 - If your printer is in a cold location you need to preheat your bed for at least 5 minutes to allow the print surface to reach temp (the bed temperature is measured right by the heater not at the build plate

If you are printing PETG on glass you need to use the glue as a release agent since PETG loves to adhere strong enough to chip out glass.

If you use glue clean the bed well, apply the glue then heat the bed up to dry it out.

If printing ABS then dissolving a few grams of ABS in 50ml of acetone then painting the bed with a thin coating will get great adhesion.

I watched a video and these guys use windex on the glue, then a razor, and finally isopropyl. They applied a coating of glue, let it dry and then covered the glass again perpendicular to the first coating after it dried.The glass bed on my old Robo3D needed glue for everything. I used Aquanet Super Hold spray, but glue stick should work fine. Both are PVA glues.

BTW, I found Windex removes PVA glue faster than soap and water.

The glass bed on my old Robo3D needed glue for everything. I used Aquanet Super Hold spray, but glue stick should work fine. Both are PVA glues.

BTW, I found Windex removes PVA glue faster than soap and water.

If you have a clean, level print surface you shouldn't need glue stick for PLAI watched a video and these guys use windex on the glue, then a razor, and finally isopropyl. They applied a coating of glue, let it dry and then covered the glass again perpendicular to the first coating after it dried.

Do you have the AMS? Does it print more than PLA? Nylon, ABS, etc?

Doesn’t look it. So I guess the next question: Best printer (out of the box) for nylon under $1k?

Qidi x max 3?

which AMS.Bringing this back up again

which AMS.

The AMS vs AMS lite, it depends less on the AMS and more on the printer. For instance the A1 Mini, A1, P1P, should really just be PLA, PETG, TPU, and PVA. Its not really the AMS being the limiting factor. More so the fact that they are not enclosed.

Having an enclosed chamber, and even better a heated chamber allows you to work with ASA, ABS, PET, PC, and other exotic filaments

Yea sorry, sounded like you were asking about printing with an AMS.That was a lot of words, none of which answered either question.

He posted about the P1S, which is what I asked about. Compared to the Qidi printers.

I am not asking you how or what I need to print nylon. I already do that.

The questions are: How is the P1S, do you use the AMS and does it print nylon?

What is the best nylon capable printer under $1k?

Yea sorry, sounded like you were asking about printing with an AMS.

What nozzle is in the AMS? Bambu warns that any AMS may suffer "wear to AMS PTFE tubes during the printing process" when used with abrasive filaments, e.g. CF or GF filament, but also states that the PTFE tubes are consumables, so you're eventually going to need to replace them no matter what filament is used.Just curious about it. I read that the AMS can’t do cf nylon bc it will damage the nozzles

On any printer, if you're going to print CF/GF filled you will want a hardened extruder gear and hardened print nozzle and maybe move up to a .6 or even .8 nozzle.

What nozzle is in the AMS? Bambu warns that any AMS may suffer "wear to AMS PTFE tubes during the printing process" when used with abrasive filaments, e.g. CF or GF filament, but also states that the PTFE tubes are consumables, so you're eventually going to need to replace them no matter what filament is used.

If you see yourself getting into advanced filaments, go with the X1C for the hotter build plate, hardened nozzle and gears, LiDAR , etc.

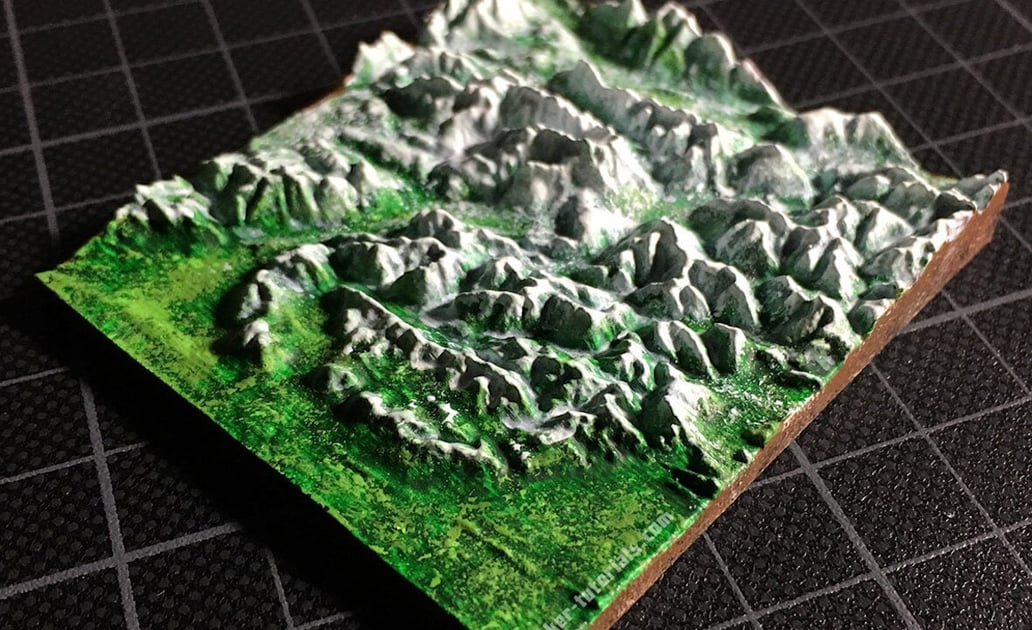

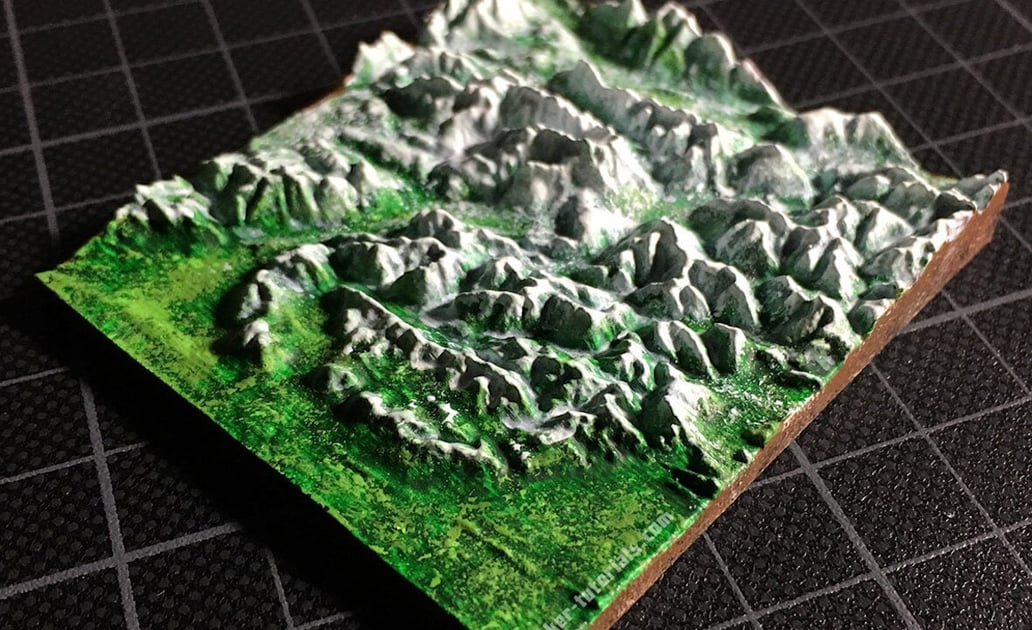

This is a bit of a stretch, but is there software that can slice a topo map and print that terrain?

I can crudely use some CAD software, but the key there is crude. Building terrain by hand... no.

At a quick skim reading, that's a little daunting. But I'll dig deeper. Thanks.

3D Printing Topographic Maps: How to Print Landscapes

Topographical and relief map data are useful for 3D printing topographic maps. Learn all you need to know to print your own!all3dp.com

You can do okay without an enclosure as long as you are only using PLA, PETG, TPU, and maybe (with a really hot bed) small prints in ABS. But with ABS, ASA, you'll wish you had an enclosure with a carbon filter.Are enclosures over rated?

I have one coming today. No idea if it has metal supports but it has led lighting which is a plus to me.