-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

-

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2018 Cast Bullet Seminar Sign Up Thread

- Thread starter 38ExtraSpecial

- Start date

38ExtraSpecial

NES Member

I think as long as the alloy is straight pure lead that the coating won’t be an issue.I thought Muzzle loaders use of straight lead best.

Sure won’t matter for a patched round ball either way.

It would keep your round balls from oxidizing sitting around.

pastera

NES Member

Payment sent

If no one else can do it I'll pick it up the week before (going to be traveling for work so I can't pick up earlier)

Anyone willing to swing to hanover to grab the lead from MAC1911 before the seminar?

If no one else can do it I'll pick it up the week before (going to be traveling for work so I can't pick up earlier)

MaverickNH

NES Member

Hmmm. That’s a great idea. I can’t see why it wouldn’t work.

I’ll search up a mold to bring along. I don’t think muzzleloader bullets are sized but why not try? I found this Thor™ Bullet Sizing Pack - .500 to .503 Diameter

EddieZoom

NES Member

Anyone willing to swing to hanover to grab the lead from MAC1911 before the seminar?

I can grab it.

38ExtraSpecial

NES Member

Sweet either way.Payment sent

If no one else can do it I'll pick it up the week before (going to be traveling for work so I can't pick up earlier)

It won’t let me get in with that link.I’ll search up a mold to bring along. I don’t think muzzleloader bullets are sized but why not try? I found this Thor™ Bullet Sizing Pack - .500 to .503 Diameter

I would say sizing would be a good thing.

A lot of times they’re soft swaged lead but being cast I would think sizing would be good.

Sucks trying to ram an oversized bullet down a bore.

Thanks!I can grab it.

MaverickNH

NES Member

Yeah, advice I’m getting from Cast Bullet Association forum is to get a 50cal round ball and use that to slug the barrel. It’s an in-line so I can pull the breech plug and give that a go. Also hearing pure lead is the way to go so I’ll bring that along in my pot to use. I picked up a Lee REAL 250gn double mold with handles Mold D C 45cal-250 - Lee Precision With Pure Lead, slugging seems less necessary as the bullet deforms to fit with lube added. Fiber wads with a dab of “butter” between that and BP seem to keep that delicate lead OK. Looking forward to another great time!

38ExtraSpecial

NES Member

Yeah, advice I’m getting from Cast Bullet Association forum is to get a 50cal round ball and use that to slug the barrel. It’s an in-line so I can pull the breech plug and give that a go. Also hearing pure lead is the way to go so I’ll bring that along in my pot to use. I picked up a Lee REAL 250gn double mold with handles Mold D C 45cal-250 - Lee Precision With Pure Lead, slugging seems less necessary as the bullet deforms to fit with lube added. Fiber wads with a dab of “butter” between that and BP seem to keep that delicate lead OK. Looking forward to another great time!

I might have some cast pure that will work for slugging.

Even if we use the 457” 405 grain and smack them with a hammer to bump up the diameter for slugging.

Im running the lee 250 REAL bullet in my Omega. Pure lead works well. i find you need to get the mold a bit warmer to get good fill. I run my lead hot. The slug can be a bugger to get started but i can run 10 shots before the fouling gets bad. Blackhorn209 can go about 15 shots. Accuracy is -3moa for first 5 shots.Yeah, advice I’m getting from Cast Bullet Association forum is to get a 50cal round ball and use that to slug the barrel. It’s an in-line so I can pull the breech plug and give that a go. Also hearing pure lead is the way to go so I’ll bring that along in my pot to use. I picked up a Lee REAL 250gn double mold with handles Mold D C 45cal-250 - Lee Precision With Pure Lead, slugging seems less necessary as the bullet deforms to fit with lube added. Fiber wads with a dab of “butter” between that and BP seem to keep that delicate lead OK. Looking forward to another great time!

38ExtraSpecial

NES Member

awesome sounds good. Have him PayPal me and I’ll add him to the list. Thanks Bill!Mike I have someone who is from out of the area, but will be in this area for the Seminar and wants to come he is going to get on and sign for NES his name is Mike Manning

So what do you do on a rainy Friday, if you are old and retired and don't have to work anymore????? You sit in the workshop and melt down all of the pewter that you have collected over the past couple of months. Nice pots of pewter melted down ended up with 54 ingots so about 45 to 50 lbs. Remember if you are out at yard sales don't forget those picture frames most are Pewter I got the some for free because the were broken. The other is candle stick holders they are a crap shoot some are nice thick or full pewter and others are just a thin coating over clay!!! I was just thinking by Rotometal prices that is $900.00 to a $1000.00 I may have spent $100 to $125 on it all.

- Joined

- Sep 22, 2018

- Messages

- 16

- Likes

- 26

Mike I have someone who is from out of the area, but will be in this area for the Seminar and wants to come he is going to get on and sign for NES his name is Mike Manning

Thanks Mr. Bill

38ExtraSpecial

NES Member

Some updates on some awesome donations.

Donnie Miculek of the famed Miculek family is donating Hi-Tek coating samples for each attendee. If you're not familiar with this product it's amazing. It's a game changer for hobbyist and commercial casters. This coating is thin and cures to a point where it won't melt or be dissolved by solvents. It basically turns cast into a plated bullet both hanging wise and performance wise. Awesome stuff.

Hi-Performance Bullet Coatings

Glenn Larson from White Label Lubes is donating traditional lube sticks also. Top notch products for traditional lube sizers or pan lubing. I have always used his products for my lube sizing needs and they rock. He offers a variety of lubes from soft 50/50 lube that flows quick and doesn't need a heater for your sizer to Carnauba Red which is a very high performance lube for hotter loads and also great for storage and handing because it's firmer and will not pop out of the lube grooves like some of the harder lubes you see from commercial casters.

Zen Cart!, The Art of E-commerce

I'm also going to have some commercial #10 cans for general casting use. Great for small batches of water dropping or I prefer to use them for dropping sprues into. They're a good size to work with and can handle the heat of the hot sprues.

Donnie Miculek of the famed Miculek family is donating Hi-Tek coating samples for each attendee. If you're not familiar with this product it's amazing. It's a game changer for hobbyist and commercial casters. This coating is thin and cures to a point where it won't melt or be dissolved by solvents. It basically turns cast into a plated bullet both hanging wise and performance wise. Awesome stuff.

Hi-Performance Bullet Coatings

Glenn Larson from White Label Lubes is donating traditional lube sticks also. Top notch products for traditional lube sizers or pan lubing. I have always used his products for my lube sizing needs and they rock. He offers a variety of lubes from soft 50/50 lube that flows quick and doesn't need a heater for your sizer to Carnauba Red which is a very high performance lube for hotter loads and also great for storage and handing because it's firmer and will not pop out of the lube grooves like some of the harder lubes you see from commercial casters.

Zen Cart!, The Art of E-commerce

I'm also going to have some commercial #10 cans for general casting use. Great for small batches of water dropping or I prefer to use them for dropping sprues into. They're a good size to work with and can handle the heat of the hot sprues.

Some updates on some awesome donations.

Donnie Miculek of the famed Miculek family is donating Hi-Tek coating samples for each attendee. If you're not familiar with this product it's amazing. It's a game changer for hobbyist and commercial casters. This coating is thin and cures to a point where it won't melt or be dissolved by solvents. It basically turns cast into a plated bullet both hanging wise and performance wise. Awesome stuff.

Hi-Performance Bullet Coatings

Glenn Larson from White Label Lubes is donating traditional lube sticks also. Top notch products for traditional lube sizers or pan lubing. I have always used his products for my lube sizing needs and they rock. He offers a variety of lubes from soft 50/50 lube that flows quick and doesn't need a heater for your sizer to Carnauba Red which is a very high performance lube for hotter loads and also great for storage and handing because it's firmer and will not pop out of the lube grooves like some of the harder lubes you see from commercial casters.

Zen Cart!, The Art of E-commerce

thats awesome . White label is good stuff. I run 2500 for everything.

I'm also going to have some commercial #10 cans for general casting use. Great for small batches of water dropping or I prefer to use them for dropping sprues into. They're a good size to work with and can handle the heat of the hot sprues.

Love Machine

NES Member

Cooooool.

OK!! I was able to pick up some Pewter. It was $4.80 a pound so that's what I am going to sell it for, it has been XRF gun verified as Pewter. If people want some it will be there. I have 50 pounds of pure lead pipe to donate to the Seminar. I am donating an old lead melting pot and dipper that can be given away as a door prize along with a few other things that should be on the way.

EddieZoom

NES Member

Attachments

Love Machine

NES Member

Sadly the hydroforming die won't come from Whidden for another month. So no hydroforming 5.45 cases at the reloading workshop.

pastera

NES Member

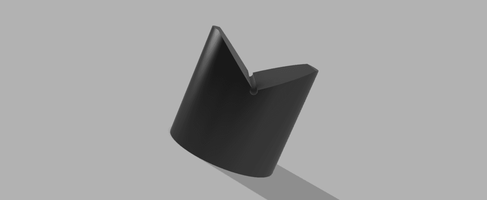

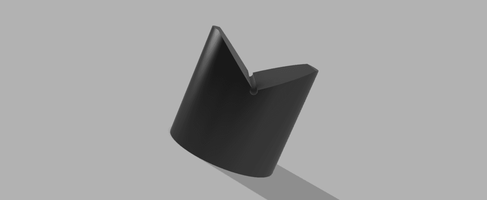

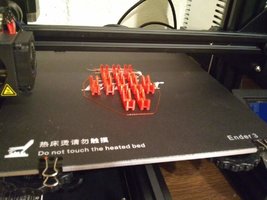

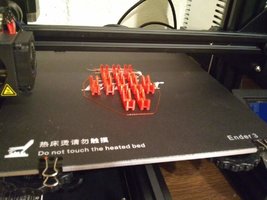

Want to slug your 5 groove barrel? Too bad for you, you can't get an accurate reading with standard calipers or micrometers.

I printed up three micrometer adapters that allow an accurate measurement - checked all three and had a worst case error of -0.3%

The adapters slip over the micrometer's spindle and use a simple math function (can supply a spreadsheet) to give you the correct diameter.

Just need a count to bring to the seminar.

For those with only calipers - I'm working on an adapter for calipers but calipers aren't really accurate enough to do the job properly. If I can get one that prints up well and is reasonably accurate, I'll offer those up also.

PS: If you have an even number of grooves, then standard tools work. If you have a different odd number of grooves, PM me and I'll try to print out the proper V-angle for that number of grooves.

I printed up three micrometer adapters that allow an accurate measurement - checked all three and had a worst case error of -0.3%

The adapters slip over the micrometer's spindle and use a simple math function (can supply a spreadsheet) to give you the correct diameter.

Just need a count to bring to the seminar.

For those with only calipers - I'm working on an adapter for calipers but calipers aren't really accurate enough to do the job properly. If I can get one that prints up well and is reasonably accurate, I'll offer those up also.

PS: If you have an even number of grooves, then standard tools work. If you have a different odd number of grooves, PM me and I'll try to print out the proper V-angle for that number of grooves.

38ExtraSpecial

NES Member

Want to slug your 5 groove barrel? Too bad for you, you can't get an accurate reading with standard calipers or micrometers.

I printed up three micrometer adapters that allow an accurate measurement - checked all three and had a worst case error of -0.3%

The adapters slip over the micrometer's spindle and use a simple math function (can supply a spreadsheet) to give you the correct diameter.

Just need a count to bring to the seminar.

For those with only calipers - I'm working on an adapter for calipers but calipers aren't really accurate enough to do the job properly. If I can get one that prints up well and is reasonably accurate, I'll offer those up also.

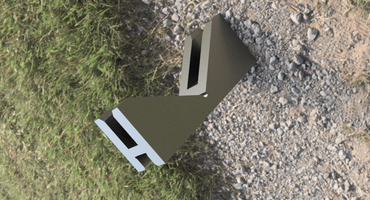

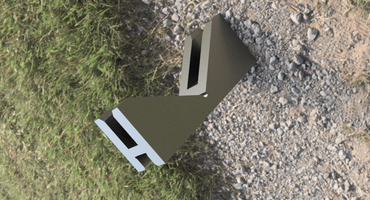

View attachment 249326 View attachment 249327

PS: If you have an even number of grooves, then standard tools work. If you have a different odd number of grooves, PM me and I'll try to print out the proper V-angle for that number of grooves.

That’s amazing!!! Thanks man!! Great work

pastera

NES Member

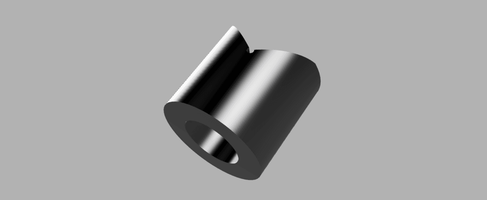

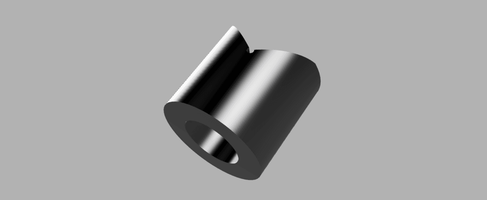

Okay, got the caliper adapter done, tested SAT and printed out ten for now.

The rendering makes it look much larger than it is (longest dimension is 1")

What you need to use this:

1 - To use it you need a known 'd' to find 'v' - use the (2) formula (from the link) and a reference round stock (measure the round before attaching the adapter)

2 - Attach the adapter and measure the slug from your barrel - make sure you turn it to find the max reading - This is 'h'

3 - Plug 'v' and 'h' into formula (3) to get your barrel's diameter

PM me an email for the spreadsheet, STL file to print your own, or the Fusion 360 design if you want to change it (different number of grooves, fit a different width caliper, etc)

If ten won't cover demand, let me know so I can print more out - Or if there is a different odd numbered groove count needed

The rendering makes it look much larger than it is (longest dimension is 1")

What you need to use this:

Calipers - you don't need expensive calipers but the cheap plastic ones are not going to give good results

A couple of reference rounds (closer in diameter to your bullet is better) - a good quality drill bit or grab the ground shaft out of an old laser/inkjet printer

Some calculations - A description is here: www.practicalmachinist.com/vb/gunsmithing/measuring-5-groove-slugs-189215/ (I made a spreadsheet so that you can just plug in the numbers)

Adapter fits over the movable jaw on your calipers.A couple of reference rounds (closer in diameter to your bullet is better) - a good quality drill bit or grab the ground shaft out of an old laser/inkjet printer

Some calculations - A description is here: www.practicalmachinist.com/vb/gunsmithing/measuring-5-groove-slugs-189215/ (I made a spreadsheet so that you can just plug in the numbers)

1 - To use it you need a known 'd' to find 'v' - use the (2) formula (from the link) and a reference round stock (measure the round before attaching the adapter)

2 - Attach the adapter and measure the slug from your barrel - make sure you turn it to find the max reading - This is 'h'

3 - Plug 'v' and 'h' into formula (3) to get your barrel's diameter

PM me an email for the spreadsheet, STL file to print your own, or the Fusion 360 design if you want to change it (different number of grooves, fit a different width caliper, etc)

If ten won't cover demand, let me know so I can print more out - Or if there is a different odd numbered groove count needed

Share: