The bit sets are a good place to start. I've filed a few down to fit my Smiths frames.

So it looks like that holds the receiver pieces together?

The good news is, you're not completely f**ked. You'll be ordering a replacement bolt though.

The soldering iron trick and penetrating oil will get it loose. Heat and repeat.

Worst case scenario- You'll end up drilling that out in increments starting with wire gauge and going up to bolt shank dia minus several thousandths to stay off the threads and relieve tension.

Not something I'd attempt with out a drill press.

View attachment 427498

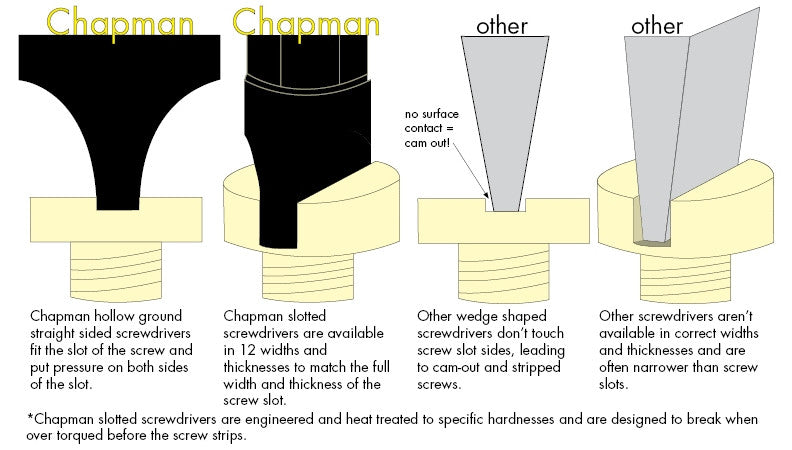

chapmanmfg.com

![ROFL [rofl] [rofl]](/xen/styles/default/xenforo/smilies.vb/013.gif)