-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

J-Frame or Kahr PM9 ????

- Thread starter JohnnyC

- Start date

cmacclel

NES Member

dcmdon

NES Member

I see your pics and kindof say "so what". Remember, smith has a lifetime service policy.

Call them up and they'll take care of you, they'll even pay to ship it back to them.

What model is that? It doesn't look like an alloy frame. Its obviously not a 340 or 342.

Call them up and they'll take care of you, they'll even pay to ship it back to them.

What model is that? It doesn't look like an alloy frame. Its obviously not a 340 or 342.

cmacclel

NES Member

I see your pics and kindof say "so what". Remember, smith has a lifetime service policy.

Call them up and they'll take care of you, they'll even pay to ship it back to them.

What model is that? It doesn't look like an alloy frame. Its obviously not a 340 or 342.

Hmm "So WHat" is not what I expected hear.

It's a 360pd

"Smith & Wesson combined a scandium alloy frame with a titanium cylinder to build the strongest and lightest weight .357 magnum revolver ever made."

Mac

Hmm "So WHat" is not what I expected hear.

It's a 360pd

"Smith & Wesson combined a scandium alloy frame with a titanium cylinder to build the strongest and lightest weight .357 magnum revolver ever made."

Mac

Hopefully S&W would take care of you. However, the frame was originally anodized and putting any sort of coating on top of that is probably not going to work well. It would have been better to send it back to them at the first sign of corrosion. If it corroded like you're saying, either the anodizing job wasn't done right or it was damaged.

cmacclel

NES Member

Hopefully S&W would take care of you. However, the frame was originally anodized and putting any sort of coating on top of that is probably not going to work well. It would have been better to send it back to them at the first sign of corrosion. If it corroded like you're saying, either the anodizing job wasn't done right or it was damaged.

This is an everyday carry gun and has been carried everyday since purchased a few years ago. When the corrosion first started I told him " I would send that back" but he does not even remotely care about the cosmetics of this EDC pistol and not want to be without it for the amount of time it was going to take with S&W. There is also no issue with coating over anodization in fact duracoat and cerrakote state this in their product data sheet if I recall correctly.

dcmdon

NES Member

CMA ,

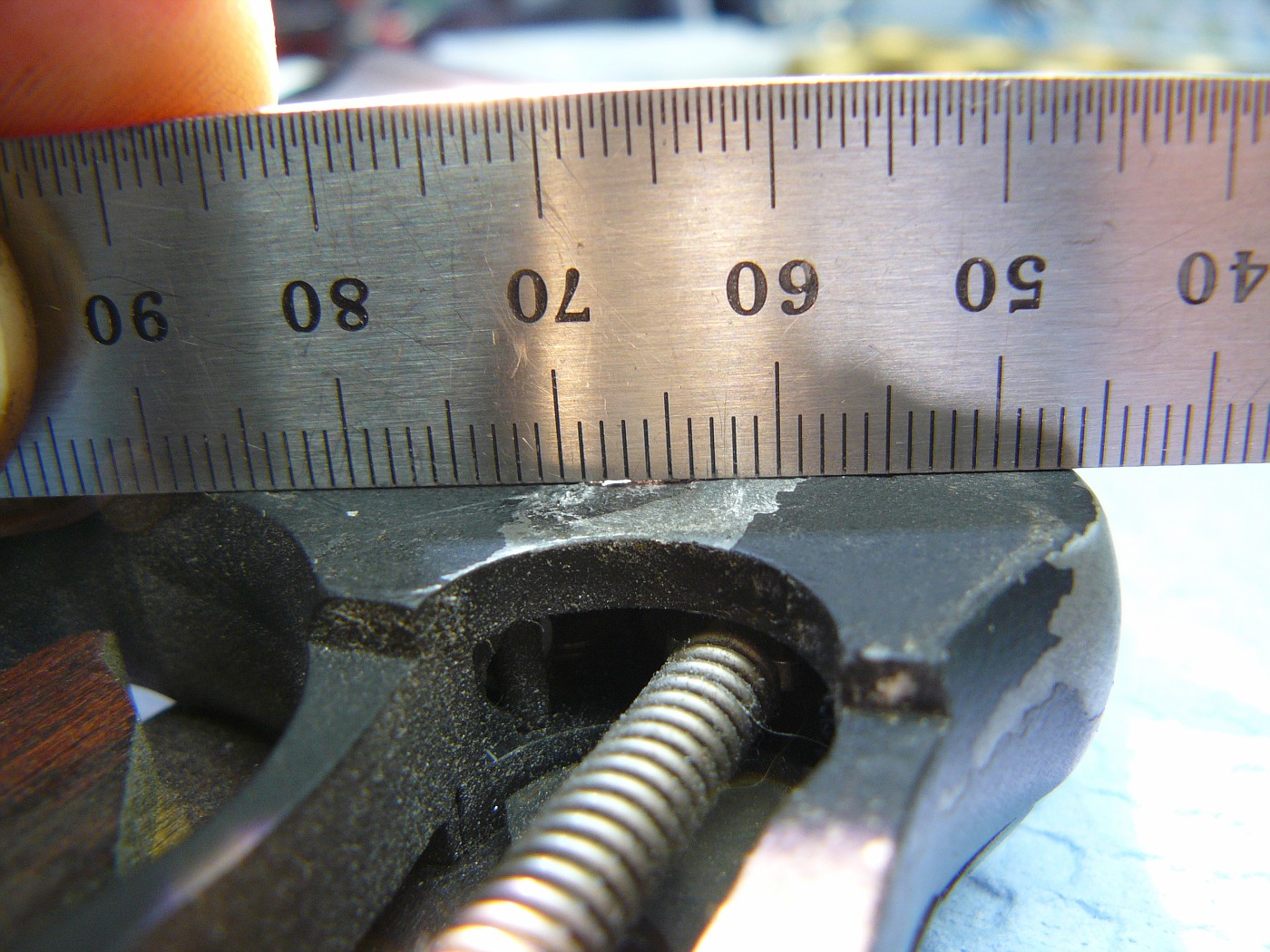

I was kindof kidding. The bottom line is that S&W would take care of it with about a 2 week turnaround. I didn't think it could be a 3 series gun because I saw some kind of paint flaking off and anodizing doesn't flake. Your explanation that he painted it, now clears things up.

I do have another question. And I'm not trying to be flippant but does this guy take care of his stuff? It looks like its been used as a hammer. The finish is worn off the top of the backstrap, that makes no sense. Also, its filthy inside. I'm not one of these guys who treats his guns like fine china but if its a gun I depend on I at least spray it out with some WD40 (please don't jump on me, its a great degreaser that leaves a film behind, far better than most gun scrubbs that leave the metal completely dry), then blow it out with some air, then lube it up.

If he treats his stuff well, then it looks like hell because of a bad anodizing job. My 340 gets carried about 10% of the time, so I can't really compare my use with his. But my LCP gets carried nearly every day. Its getting the normal smooth wear on the slide, almost a burnishing that adds character.

That gun just looks like its been abused or the anodizing was crap from the factory.

*****Now here's the million dollar question. Does anyone know of any other cases, first hand only please, of similar corrosion on a Al/Sc framed gun? One bad gun does not make for a reason not to buy a gun. ****

I was kindof kidding. The bottom line is that S&W would take care of it with about a 2 week turnaround. I didn't think it could be a 3 series gun because I saw some kind of paint flaking off and anodizing doesn't flake. Your explanation that he painted it, now clears things up.

I do have another question. And I'm not trying to be flippant but does this guy take care of his stuff? It looks like its been used as a hammer. The finish is worn off the top of the backstrap, that makes no sense. Also, its filthy inside. I'm not one of these guys who treats his guns like fine china but if its a gun I depend on I at least spray it out with some WD40 (please don't jump on me, its a great degreaser that leaves a film behind, far better than most gun scrubbs that leave the metal completely dry), then blow it out with some air, then lube it up.

If he treats his stuff well, then it looks like hell because of a bad anodizing job. My 340 gets carried about 10% of the time, so I can't really compare my use with his. But my LCP gets carried nearly every day. Its getting the normal smooth wear on the slide, almost a burnishing that adds character.

That gun just looks like its been abused or the anodizing was crap from the factory.

*****Now here's the million dollar question. Does anyone know of any other cases, first hand only please, of similar corrosion on a Al/Sc framed gun? One bad gun does not make for a reason not to buy a gun. ****

Last edited:

cmacclel

NES Member

Every one of his guns are mechanically better than when it left the factory he is pretty much our in-house gunsmith. The dirt you see in the picture was under the grip which I took off to take the pictures. Do you take your grips off when cleaning your pistols? He has been working in a machine shop for the past 21 years so the gun gets banged around from time to time and multiply that x almost 4 years of every day carry and you get what you see in the pictures. As for the 360PD you should'nt have to spray oil ar anything on it as it's not supposed to have any corrosive metal besides maybe the hammer and cyclinder release.

One bad gun? Did they use different metal / alloys on his?

Mac

One bad gun? Did they use different metal / alloys on his?

Mac

Last edited:

Now I'm all paranoid about people with GSG-style super-sweat instant rusting my guns.![Roll Eyes [rolleyes] [rolleyes]](/xen/styles/default/xenforo/smilies.vb/042.gif)

Don't worry, I warn people if their gun looks like something I'll go Midas on.

![Wink [wink] [wink]](/xen/styles/default/xenforo/smilies.vb/002.gif)

Also, I'm a little dubious of people making coated stainless rust (like the black slides on some Kahrs, S&W M&Ps, SIGs, etc) since that's like a belt and suspenders.

I'll post a picture or scanned copy of a work order I have from Remington; I put rust on a nickel 870 Marine Magnum and they replaced a bunch of parts for me. Other people from NES have seen some of it first hand on my guns. I took most of it off of a Glock that got it the worst, but there's still a spot of it on the trigger, I'll see if I can get a picture of that too. I owned the Sig years ago and never took pictures, and I've never owned an M&P.

I make it a point to touch the metal on my guns as rarely as physically possible, but I've found rust where my cheek touched the reciever of 2-3 parkerized shotguns after getting home from the range. Blued steel is a whole different ballgame. KelTec bluing takes me about a month to put rust on, I thought hard chrome would be more rust resistant but it's a flat finish similar to Kahr, so no dice.

I baby my guns too, I don't act like a trailer park husband with them or anything.

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif)

Oh I also put rust on the coated blade of a friend's Kershaw Blur after EDC for a few weeks. The Leek and Scallion I bought lasted less than two weeks each.

*****Now here's the million dollar question. Does anyone know of any other cases, first hand only please, of similar corrosion on a Al/Sc framed gun? One bad gun does not make for a reason not to buy a gun. ****

Not from me. I used to carry a 642 and I put rust on the barrel, cylinder, cylinder release and grip screw, but I never had issues with the aluminum frame. I believe that took me 2-3 months to put rust on, it was fairly minor all things considered, light surface rust. I owned it at the same time as the Sig though, so it seemed like nothing in comparison. I shot a buddies scandium 1911 once and he didn't b*tch after that it rusted up or anything, but that 5 minutes or so was the most contact I ever had with one.

dcmdon

NES Member

Jesus man, you should be tested or something.

Are you sure you don't store your guns loosely wrapped in muslin on the floor in the basement of your dirt floor beach cottage??

Are you sure you don't store your guns loosely wrapped in muslin on the floor in the basement of your dirt floor beach cottage??

Jesus man, you should be tested or something.

Are you sure you don't store your guns loosely wrapped in muslin on the floor in the basement of your dirt floor beach cottage??

I've never been tested. My dad has similar issues, although not as bad as mine. A gunstore employee (I know, I know) once told me that the oils on my skin may have a high alkalinity, and to stop eating spicy foods. That didn't help.

My guns are stored with dessicant, kept well oiled, rarely touched, and wiped down regularly. I wasn't as careful with the 870 because it's designed for salt water corrosion resistance, so I figured it wouldn't hurt it so much. Yeah, my mistake, back to cleaning with rubber gloves on and rarely handling it.

Yeah, as I've mentioned elsewhere, stainless will rust but it takes a lot more to make it happen and it happens much more slowly. That said, someone mentioned previously in this thread of getting a scandium (aluminum) j-frame to corrode and I assume those are anodized. If those are anodized and the gun has been treated well, it won't corrode.

Also, I'm a little dubious of people making coated stainless rust (like the black slides on some Kahrs, S&W M&Ps, SIGs, etc) since that's like a belt and suspenders.

You can make anything corrode if it's made out of metal and you try hard enough.

![Wink [wink] [wink]](/xen/styles/default/xenforo/smilies.vb/002.gif)

I remember seeing some pics of a gun safe that was "dunked" during Katrina for like a week, basically submerged in water, chemicals, poop, whatever else was

floating around in that water in NOLA. The results were kind of interesting. I wish I could find the post, it was on Sigforum or THR.

Most of the guys rifles and shotguns were ruined, IIRC. Those pictures were just plain sad.

The handguns fared much better, but the results were kind of bizarre. The Sig the guy had, had light spots of rust in different places, but it was still otherwise OK. The Glock was OK except the internals (eg, trigger bar, etc) were all rusted to hell. The HK USP was nearly immaculate, with one exception- the slide lock/takedown pin on the gun was rusted to hell. It looked really weird, because the slide itself, and the barrel, were perfectly clean and undamaged. I think he had a couple of other handguns that got pretty much ruined, but I don't remember what the hell they were. I'd bet one of them was parkerized. You pretty much look at a parked 1911 the wrong way and rust will start forming on it.

An S&W 340 should be the ultimate in corrosion resistance. Titanium doesn't corrode and the anodized aluminum frame shouldn't either unless damaged.

I've seen things like 637s/642s that get "frosty" after being carried a lot... whether this is some type of genuine corrosion or not, I don't know. With the super airweight things (the 12 ounce scandium .357s) eg, the 340PD, you have a high likelihood of the gun grenading itself before the finish corrodes anyways. (At least 2 people on NES have blown up these things, and I know one guy personally who has blown up the exposed hammer version of the thing.... and all of them failed at low round counts. ) so the finish isn't a big concern on those guns anyways... if the finish is just bad, just keep shooting it, and it will blow up again, at which point you'll get a new gun. (I'm half kidding here... most of the time the 2nd time around the user gets a gun that won't blow up. I don't think I've met anyone yet that has managed to blow up 2 of them. )

http://www.thegunzone.com/sw340pd.html

http://lonelymachines.org/2009/11/08/pushing-the-envelope-vs-pushing-your-luck/#more-1478

-Mike

Last edited:

The 442 isn't blued. It has an aluminum frame.Can anyone tell me how easily the blueing is scratched on a 442? I want to pocket carry but I dont want it looking too bad.....I think an ankle rig is going to be best here.

Also, all CCW guns that are carried regularly will wear. Stop worrying about how it looks.

You can make anything corrode if it's made out of metal and you try hard enough.![Wink [wink] [wink]](/xen/styles/default/xenforo/smilies.vb/002.gif)

Not quite! </contrarian>

Gold and titanium would have survived!

I'd still like to know the typical stainless steel alloys gun manufacturers use. I get the impression they're on the harder/stronger end of the scale which does mean they're more likely to rust. If you go to the hardware store and buy a typical stainless bolt, those things will stand up to salt water quite well, but they're also very soft. I looked up a torque table for one and stainless was rated slightly higher than brass.

I'm glad I don't have GSG's chemistry. I think the CIA should hire him, give him a heavy coating of tan in a bottle and send him to Iran's nuclear plant to touch things.

Dirtypacman

NES Door Greeter

The 442 isn't blued. It has an aluminum frame.

Also, all CCW guns that are carried regularly will wear. Stop worrying about how it looks.

A carry gun deserves the wear and tear - builds character.

dcmdon

NES Member

So lets look at this practically.

GSG has some strange kryptonite acid bath sweat. That means we can throw out all his stories of corrosion except for his guns that DON'T corrode. Seriously.

If he finds a gun that he can't make corrode, it would represent something that is very very corrosion resistant.

Now on to the rest of us.

Don

GSG has some strange kryptonite acid bath sweat. That means we can throw out all his stories of corrosion except for his guns that DON'T corrode. Seriously.

If he finds a gun that he can't make corrode, it would represent something that is very very corrosion resistant.

Now on to the rest of us.

Don

dcmdon

NES Member

A carry gun deserves the wear and tear - builds character.

There is a difference between character earned by daily carry like this one:

and one thats been neglected or abused.

That looks nice.There is a difference between character earned by daily carry like this one:

dcmdon

NES Member

Its owned by a guy with the screen name USMC 0802 on 1911forum.com

He's got somewhere around 30,000 rounds on this 3-4 year old Baer. Somewhere he posted a pic of him going to the range with a couple of 6 galon taping buckets filled with reloaded .45s.

He's got somewhere around 30,000 rounds on this 3-4 year old Baer. Somewhere he posted a pic of him going to the range with a couple of 6 galon taping buckets filled with reloaded .45s.

Is that hockey tape?

Also, notice there are no nasty abrasions on it, and no corrosion. Thats to me a well used but not abused gun.

I was joking. It's from this: http://www.imfdb.org/index.php/Book_of_Eli,_The

I do think it looks cool though.

I'm glad I don't have GSG's chemistry. I think the CIA should hire him, give him a heavy coating of tan in a bottle and send him to Iran's nuclear plant to touch things.

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif) I couldn't do anything that their free porn site computer viruses aren't doing already.

I couldn't do anything that their free porn site computer viruses aren't doing already.A carry gun deserves the wear and tear - builds character.

Yes!

So lets look at this practically.

GSG has some strange kryptonite acid bath sweat. That means we can throw out all his stories of corrosion except for his guns that DON'T corrode. Seriously.

If he finds a gun that he can't make corrode, it would represent something that is very very corrosion resistant.

Now on to the rest of us.

Don

I've never put rust anywhere on a 2nd gen Glock, and I've done some serious sweating on them, in addition to carrying them exposed in the rain and snow. Nary a speck of rust on them, despite lots of holster wear from practicing draws daily and handling the internals while cleaning (without gloves). It wasn't until I got into other guns that I realized wiping down the gun a couple times a day, very regular cleaning and throwing other carry guns into the mix were required to keep corrosion at bay.

But to give an accurate picture of what I don't rust I'd have to post a complete inventory of my gunsafe, which isn't going to happen. Let me put it this way; aside from 2nd gen Glocks, I put rust on every gun that I handle, with some it just takes longer than others. There are a few guns however that I don't believe I'll make rust, although I've never shelled out the $$$ to test these theories. They include, but are not limited to, nickel Bersas, stainless Springfield XD's, and guns that have been Duracoated.

(A closer inspection of one of my 3rd gen Glocks shows that rust is returning in 2-3 areas. I'll try to get a picture of it in the next few days)

Share: