Thanks for the heads up 7.62. I will check it out... Please PM me with what you feel would be a fair offer for the unit.

Are there any good magazines to subscribe to for an entry level machinists that you would recommend?

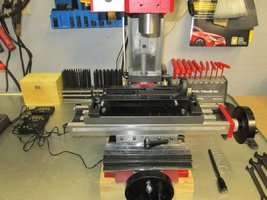

Now that I have a couple new toys, I want to learn how to use them.![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)

LMS has a library full of stuff available. Videos, Books & Seminars - LittleMachineShop.com

You can also rent with option to buy DVDs from swarfrat himself.

http://www.swarfrat.com/

![Bow [bow] [bow]](/xen/styles/default/xenforo/smilies.vb/027.gif)