Received my latest CMP Garand last week. CMP Service grade H&R manufactured M1 Garand. Serial dates to 1955 along with 12-55 barrel. All but the gas plug and trigger group assembly appear to be HRA. Finish is very nice and appears to be original barrel. No pitting. Came with new cmp stock set. As with all my past Garands I started with a detail strip, clean and inspection http://www.civilianmarksmanship.com/detailstrip.html

On this rifle I passed on checking every part for proper specifications per http://estore.thecmp.org/store/cata...pmax=¬e1=¬e2=¬e3=¬e4=¬e5=&max=

As I resembled the rifle I performed the tilt test in the various stages. This is the only video I could find that covers this. My HRA failed #2 and #4 test. The Op rod on mine rubs on the belly of the stock and along the upper hand guard on the edge along the op rod travel. http://www.youtube.com/watch?v=tlIoxbtdPXY I have a Service grade Springfield that falis this test also but shoots good. Its a USGI stock so I did not mess with it. This may or may not matter depending on the amount of contact and the rifle may function just fine.

http://www.youtube.com/watch?v=tlIoxbtdPXY

The detail strip is really good to do. Even though the rifles appear to be "clean" from the cmp they are not really clean.

1. barrel had a good amount of copper fouling. Took approx 40 patches before the "blue" tint on the patch was just faint

2. The amount of grit and crud/dust in the rear sight assembly is pretty nasty. A plus to detail strip of the rear sight is once cleaned oil and lubed the sight adjustments will be smoother and easier to turn the knobs.

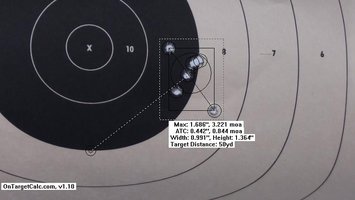

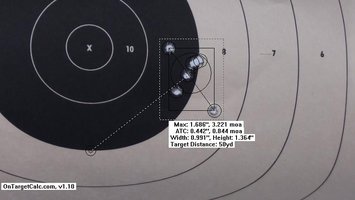

Ok reassembled and lubed per CMP recommendations off to the range I go with 2 HXP 1972 en bloc clips. All I had time for. I set my targets at 50 yards as this is easier to see whats going on with the groups especially windage. Today was a function day more than anything. For the most part all functioned well. Below is the 2 groups I shot From a lead sled rifle rest. I will say this particular rifle has a nice trigger. As you will see my "7" shot groups where not terrible. I did not have time or my spotting scope to track my shots so no info for what shot did what ?

As you can see from the pics this garand is probably well with the specs for government work. The groups are very similar. 4 vertical stringing and a left and right "flyer" I am almost certain if I tracked the shots I would bet the two groups would match almost shot for shot as far as impact goes. ie: 1st shot goes left? As you see there is only 7 shots in each group. That's because on the seventh shot with both groups jammed up. Garands where know to have a 7th round issue with the early models. I can bet this is caused by the op rod binding.

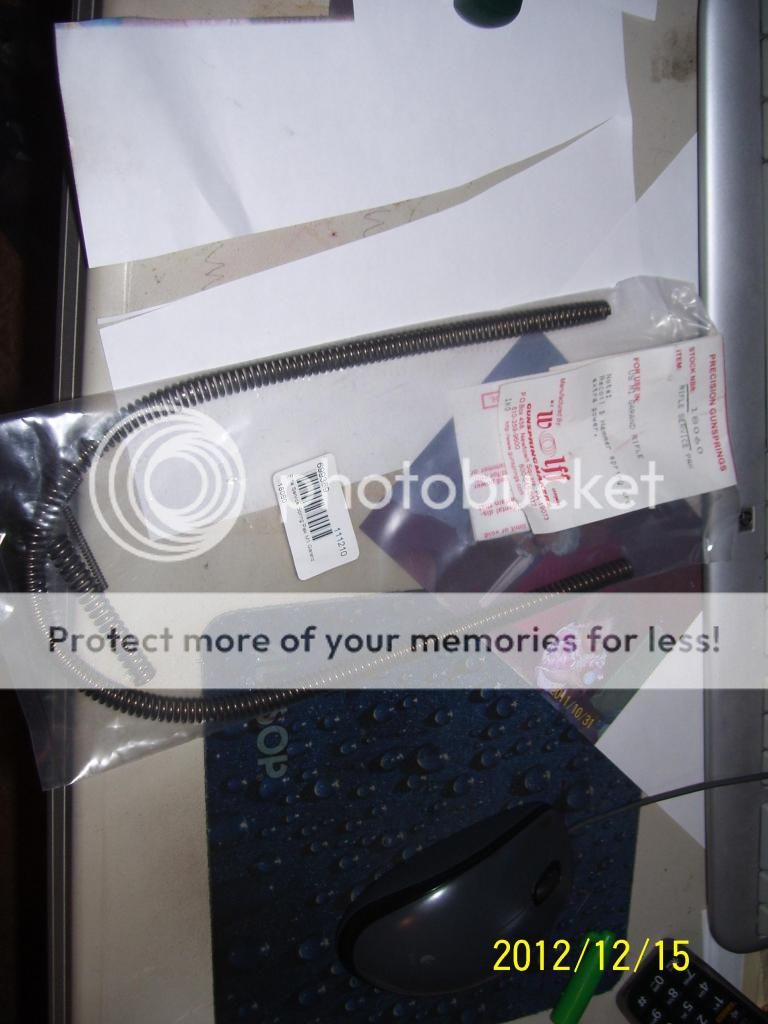

I will post the mods I do along the way. I will start by fitting the wood better. There is a good amount of info out there for "accurizing the M1" I followed a article in american rifleman. I cant find a link that works right now but its out there. So far my garands have all benefited from "Accurizing". I do not do anything that will render it illegal for the JCG matches.

On this rifle I passed on checking every part for proper specifications per http://estore.thecmp.org/store/cata...pmax=¬e1=¬e2=¬e3=¬e4=¬e5=&max=

As I resembled the rifle I performed the tilt test in the various stages. This is the only video I could find that covers this. My HRA failed #2 and #4 test. The Op rod on mine rubs on the belly of the stock and along the upper hand guard on the edge along the op rod travel. http://www.youtube.com/watch?v=tlIoxbtdPXY I have a Service grade Springfield that falis this test also but shoots good. Its a USGI stock so I did not mess with it. This may or may not matter depending on the amount of contact and the rifle may function just fine.

http://www.youtube.com/watch?v=tlIoxbtdPXY

The detail strip is really good to do. Even though the rifles appear to be "clean" from the cmp they are not really clean.

1. barrel had a good amount of copper fouling. Took approx 40 patches before the "blue" tint on the patch was just faint

2. The amount of grit and crud/dust in the rear sight assembly is pretty nasty. A plus to detail strip of the rear sight is once cleaned oil and lubed the sight adjustments will be smoother and easier to turn the knobs.

Ok reassembled and lubed per CMP recommendations off to the range I go with 2 HXP 1972 en bloc clips. All I had time for. I set my targets at 50 yards as this is easier to see whats going on with the groups especially windage. Today was a function day more than anything. For the most part all functioned well. Below is the 2 groups I shot From a lead sled rifle rest. I will say this particular rifle has a nice trigger. As you will see my "7" shot groups where not terrible. I did not have time or my spotting scope to track my shots so no info for what shot did what ?

As you can see from the pics this garand is probably well with the specs for government work. The groups are very similar. 4 vertical stringing and a left and right "flyer" I am almost certain if I tracked the shots I would bet the two groups would match almost shot for shot as far as impact goes. ie: 1st shot goes left? As you see there is only 7 shots in each group. That's because on the seventh shot with both groups jammed up. Garands where know to have a 7th round issue with the early models. I can bet this is caused by the op rod binding.

I will post the mods I do along the way. I will start by fitting the wood better. There is a good amount of info out there for "accurizing the M1" I followed a article in american rifleman. I cant find a link that works right now but its out there. So far my garands have all benefited from "Accurizing". I do not do anything that will render it illegal for the JCG matches.

Last edited:

![Wink [wink] [wink]](/xen/styles/default/xenforo/smilies.vb/002.gif)

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)