In order to push the heavier 6.8 round faster, they increased the chamber pressure from ~60,000 PSI to 80,000 PSI. They wanted a higher velocity because it is an easy way to pack more energy into each shot: Energy = Mass * Velocity^2

When they did that, the bases on the brass cases started failing, so they went to steel bases.

Originally they were a 4-piece design, but they simplified it and there is just a steel base and brass "tube" now.

I spoke to a Sig engineer in a class at Sig. He said they had the cost of making the 2-part "brass" down into the range of .308 brass now. Remember, making a brass case is pretty annoying. They start with a slug or disc of brass and have to press/spin it through many operations to form the brass case we know and love. Making it in 2 parts allows the manufacture of each half to be much more cheaply, but now the two halves need to be pressed (or welded, I am not sure) together.

I must admit I respect Sig for thinking "out of the box" and pushing the envelopes of what is possible in small arms, but that is where my enthusiasm for this concept ends...

In my poorly informed (and irrelevant) opinion, I think the Army trying to adopt the 6.8 round and a new rifle is idiotic.

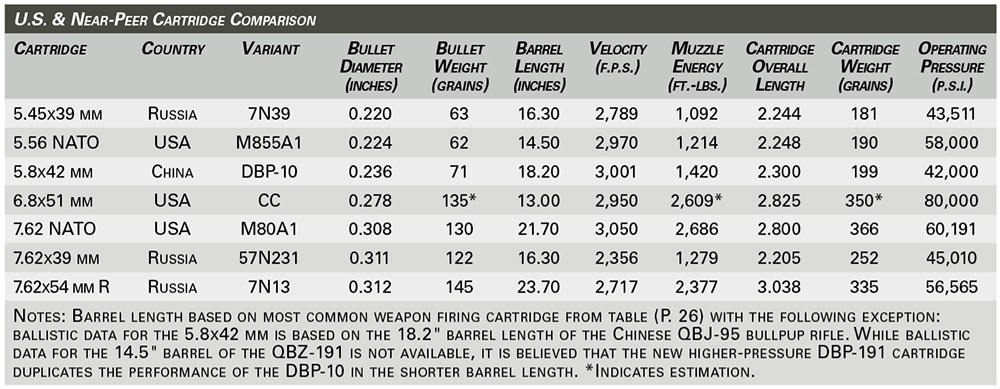

Just look at the the American Rifleman magazine a couple months ago, where they had great data comparing rounds from armies around the world. The article is mostly about the squad automatic weapon version, but the info on the cartridges are still valid.

from An Official Journal Of The NRA | Return Of The Rifleman: The Next Generation Squad Weapons Program

The article is worth reading. By the numbers, the old .308 M-14 comes out looking darn good.

Sig's 6.8 looks worse than .308 in most categories and not significantly better than most rounds used by other armies today. It is heavier than the 5.56, so they have to reduce the number of rounds soldiers will carry. Sig's XM-5 rifles are also heavier than most other options and it seems to be expected that most will run with suppressors attached, making it more awkward (and light up like a beacon through thermals). I have not seen anyone talk about recoil, but if you are putting ~30% additional velocity into the bSo

![ROFL [rofl] [rofl]](/xen/styles/default/xenforo/smilies.vb/013.gif)