Thanks for the very detailed info. I may end up having someone do this for me depending on how many complexities listed above I may have. I'll probably contact Northeast Arms in Peabody so see what they think (hes talked me out of bad ideas before). Actually, considering all options I may even keep what I have. Its a black diamond series which I see they still makeWith the change of the handguard likely comes a change of the barrel nut since all the different brands mentioned use different barrel nuts. This means removal of the gas block. Have you taken it all apart yet and found how aggressively YHM applied loctite and where? Lots of 600F red loctite can make disassembly a joy. Is the muzzle device pinned/welded making it impossible for assembly? Are you therefore limited to a handguard that works with the barrel nut you already have on the rifle?

Are you keeping your existing low profile gas block or changing? Not all low profiles are created equal and don't fit inside all handguards.

Two major connection methods for free float handguards, pressure and direct screw.

The pressure method will have 2 or 3 screws on the bottom that cause a pressure fit with the barrel nut. Depending on the specific nut/handguard you may have no special indexing requirements on the barrel nut or it might have a 30 or 40 correct positions per rotation of the nut that cause the handguard to align. The screws on the bottom may not be desired if you like to hold the rifle directly in front of the mag well. The screw and mount will protrude below "round" unlike the direct method.

PRO - easy to index

CON - protrudes below handguard near magwell

The direct method will have 4-6 screws that go directly into the barrel nut. This will require precise indexing of the barrel nut. Good news is spec is 35-80 ftlbs so you can usually just apply variable force. Also its a steel but into an aluminum upper so... You can also shim but then the holes for the screws need to be slots and not holes or the handguard can gap (there is always a milling machine to turn holes into slots)

PRO - lower profile possible

CON - hard to index

I am frequently amazed how much people will pay for a piece of milled and finished aluminum. You can spend $50 on a handguard or $400. They certainly can have differences in quality, finish, durability, precision, etc, but I am not sure they are usually worth the price difference. I guess the logo on the side can be worth the extra $200.

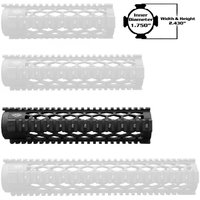

9.675" Diamond Series Forearm (Specter Length)