I didn’t know that was a thing?

Now I have to google

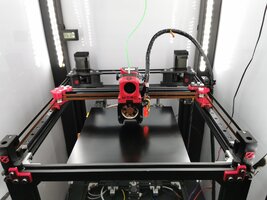

EDIT: Quick search found this Ender™ Extender Dual Z Upgrade Kit for the Ender 5

Only one motor, uses a belt to ties them together.

Barring any better ideas, which I can’t seem to find in kit form, I can’t fan my own solution and I just don’t have the time to part it out so think I will give this a go.

Bed support is a big weakness in the E5Pro

I also bought a bed heater upgrade so I will swap it all at the same time.

Last edited: