They make CF as well but research characteristics before assuming it is stronger.

Your snide comments about home gun printing are unwelcome, at best.

Your snide comments about home gun printing are unwelcome, at best.

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

I like that they actually give you the technical data along with the models used to gather the data.

PolyMide™ PA6-GF

PolyMide™ PA6-GF is a glass fiber reinforced PA6 (Nylon 6) filament. The material exhibits excellent thermal and mechanical properties without sacrificing the layer adhesion. Printing, Drying and Annealing Settings? Printing Temperature: 280˚C - 300˚CBed Temperature: 25˚C - 50˚CPrinting Speed...us.polymaker.com

I like that they actually give you the technical data along with the models used to gather the data.

@ $100 for a 2kg spool it's also extremely cheap for a mid performance filament (next jump up in temperature resistance is close to $200 for a 500g spool or 1/8 the cost)

it was a whole hotend replacement - the sprite pro direct drive extruder. they claimed it needs no code or params change - the only way to see that thermistor was actually replaced is to go to aliexpress and search for official creality replacement parts. well, now it seems to be crapping out about 320 deg that is closer to reality, i think. that thermistor should be good up to 350 deg.It’s fairly common to need non default codes when replacing the thermister. And no, they are not well documented officially but there are tons of threads in various forums covering it.

Yup...print your own reloader !!!

Dildos | Buy The Best Dildo | Adam & Eve Sex Toy Store

Shop giant dildos, realistic dildos, vibrating dildos, glass dildos, soft dildos & more. Find the dildo of your dreams at Adam & Eve. Discreet shipping.www.adameve.com

![ROFL [rofl] [rofl]](/xen/styles/default/xenforo/smilies.vb/013.gif)

Was it about what print from that carbon fiber enforced nylon?You realize that was an affiliate link, not a regular link, right?![ROFL [rofl] [rofl]](/xen/styles/default/xenforo/smilies.vb/013.gif)

if you sliced it with cura - did you activate supports?So I have a super cheap crappie chinese printer where all it did was waste filament.

I backed the AnkerMake on kickstarter and it showed up the day before yesterday.

I just printed this. I'm a complete noob, but it came out well

View attachment 701085

Now, I'm trying to print this (it's part of a present for someone). I scaled it up so it would be about 5inches tall, but every time I try to print it fails just when the pedestal part of the chair starts.

Any help here?

1-87 Barbers chair HO scale by ThatEmuGuy

Source file https://free3d.com/3d-model/barber-s-chair-v2--649221.html Scaled down for HO scale model trainwww.thingiverse.com

if you sliced it with cura - did you activate supports?

you are done, man, this shit is crazy addictive.

here is all the stuff i made so far, in 3 months, and it keeps getting better. it is fun!

| eBay

www.ebay.com

which ankermake it was - an m5 3d?

looked up its specs, looks a bit odd to me - they say it has a direct extruder, which is nice, but max temp is limited to 260. odd.

if it shows you preview - look for supports option for slicing - it has to have it.I used the slicer that came from Anker. Yes it's the Anker M5. So far it's awesome

if it shows you preview - look for supports option for slicing - it has to have it.

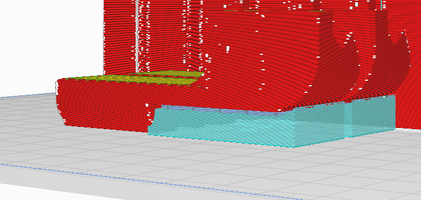

should look kinda like that in the preview - blue crap under the hanging up part of the model :

View attachment 701096

dunno anything about anker slicer. i think it works - the printer - with usual cura. i would use cura, unless there is a VERY serious reason not to.

UltiMaker Cura

UltiMaker Cura is free, easy-to-use 3D printing software trusted by millions of users. Fine-tune your 3D model with 400+ settings for the best slicing and printing results.ultimaker.com

get cura, then get profiles for cura from CHEP

CHEP's Portfolio of 3D Models on Thangs

FilamentFriday.com YouTube Channel Thangs community collaborator.thangs.com

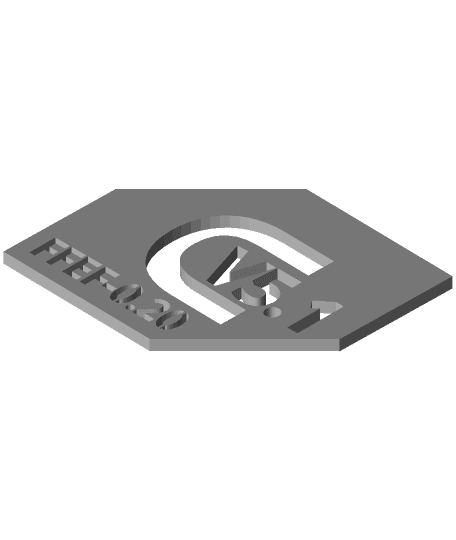

0.2 and 0.28 are most universal ones for PLA that does not take an eternity to print.

Cura V5.1 ExtraFast (0.20) Profile from Filament Friday - 3D model by CHEP on Thangs

DESCRIPTION This is my ExtraFast Profile (0.20 layer height) for Cura version 5.1. Instructions: Here is a video showing how to load them: https://youtu.be/EJD1thangs.com

www.comgrow.com

www.comgrow.com

Wait till microcenter offers their ender 3 pro for $100 again.amazon returns on sale for peanuts - for those who likes to gamble

Used Creality Printers From Amazon Return-[No Refund/Return]

Buy Creality refurbished Printers with a 1-Year Warranty Packing Notes: To ensure the safe delivery of our products, we repackage individual machines, but we guarantee that they will be original Creality machines.1. This item is 100% Creality Genuine 3D Printers. 2. We only offer after-sale...www.comgrow.com

i will try a v2 for $109 free shipping. all i need is a working frame/power supply/motors. may get a complete broken junk, of course.Wait till microcenter offers their ender 3 pro for $100 again.

I only gamble on guns

Yeah you mod the crap out of your machine so it makes sense for you. Let us know how it works out.i will try a v2 for $109 free shipping. all i need is a working frame/power supply/motors. may get a complete broken junk, of course.

then will swap out extruder for sprite pro with cr sensor combo that sells for $126 now. it makes a great combo, really, it if will work - a $240 printer that can do 310 degrees prints. so far my first modded v2 is running like a beast, prints everything perfectly great.

i run this sprite pro now for a while, and it does not clog at all, and pushes out pla+ at 100mm/s speed with no issues. really a great extruder. original extruder with tubes was just a non-stop pain, but this sprite is exceptional.

but if they ship me a junk frame, i can return this back to amazon, so, not a huge gamble.

Amazon product ASIN B0BCHCB96PView: https://smile.amazon.com/dp/B0BCHCB96P/ref=ox_ya_os_product

one day, maybe - i cannot justify $2k on a pro grade machine for what i do at the moment.I was trying to print out some gag gifts for Xmas and my trusty old Qidi, bought 7 or 8 years ago, decided it was time for the trash heap.

I broke the budget and ordered a Qidi I-Fast printer. Looks like a beast. And if I get 7 or 8 years worth of fun with it, well, I'll be happy!

Should be here next weekend!!!

well, by now i do know exactly well what i am doing with those bed slingers, as i sniffed through the design of this ender platform and most of its clones.Yeah you mod the crap out of your machine so it makes sense for you. Let us know how it works out.

They sell dry box add-onsone day, maybe - i cannot justify $2k on a pro grade machine for what i do at the moment.

looks like a great machine, 350 degrees, dual extrusion - not sure why they did not put a dry chamber on top for filament, but i guess one can retrofit external dryer boxes up there.

I just mounted a Sprite extruder on my Tronxy X5SA Pro.well, by now i do know exactly well what i am doing with those bed slingers, as i sniffed through the design of this ender platform and most of its clones.

there are many out there now, ender clones as cheap as $140 new, but, who knows how will or will not parts match, etc. ender 3 v2 comes with practically all already done - the good silent 32 bit board, power supply with no gotchas, all connectors are actually just fine, etc. i looked through mine many times now, and it really needs only minimal things to be done to it. i did to mine more than was needed.

it is a shame that creality keep this new great sprire extruder on the S1 pro model only. and, realistically, pretty much nothing that come with s1 pro is needed at all - touch screen, dual Z screw, etc.

a base ender v2 + yellow bed springs + that sprite pro all metal extruder combo with cr touch sensor - it is all that is needed for a perfectly reliable machine that prints anything - any filament in the consumer segment up to 310 degrees C. and i keep mine on 0.4mm steel nozzle.

ideally - it would be a way better idea to get an ender 5 box frame - a larger one, ideally, and put this new sprite extruder into it - but it requires a different non-existent mount plate that needs to be crafted, and it is not clear if stock cables will actually fit, but one could reposition the board then.

i looked around, but even on aliexpress it does not seem to be cheap enough or even possible to get just a metal box frame alone with stepper motors and power supply, and keep it reasonably cheap. only way to get it cheap is to hunt for those comgrow sales on returns or used stuff, but, well. even there ender 5 frames are pricey - means no way in hell of getting one for $108, and for what i do, dunno how much faster it would actually be compared to a bed slinger.

you'll need to recompile marlin and swap the value for that:I just mounted a Sprite extruder on my Tronxy X5SA Pro.

Haven't run it through its paces yet as I just got the firmware done and haven't gotten a response back from Creality on the thermistor temperature data (might have to create an accurate table to 315° myself)

I had to modify the supplied backplate and design a couple of parts but the swap is pretty easy.

3dpandme.com

3dpandme.com

I picked up the X5SA Pro for well under $300 so it was a too good to pass up deal. I was interested mostly in the speed since I can print at 150mm/sec pretty easily but the extra bed space helps a lot.you'll need to recompile marlin and swap the value for that:

#define TEMP_SENSOR_0 11

until i did that i would consistently get an error as soon as temperature would run above 295 deg somewhat.

also needs to be added - that table data induced error will be specifically misspelled as 'Nozzle is too higherature".

with the type 11 it seems to accept thermistor table up to 310-315. the thermistor itself i think should be good up to 500, but the table data is not, and i did not dig into it more.

also i need to note - when it was fresh i noticed that the temp delta between the bed and extruder thermistor readings, it was around a degree and a half when new, but after it worked for a while the delta disappeared, and now idle readings match precisely. like right now it reads 15.9C from both on idle - it is in the colder part of the basement.

i got a $108 reject ender V2 deal from the comgrow and an another sprite kit for $120 - a sprite with the cr touch sensor, as they work really neat together. the cheapest sale on sprite alone that i saw was $85. there was probably no real need for the cr touch, but, it is just a nice to have feature.

will see how it will end up. if no issues will be there - it is an amazing combo for $228.

i looked around for something like that tronxy, for a bigger box frame, but it does not seem to be anything out there for close to a $100, and i did not want to spend more, as i do not really need a 300mm chamber for anything i play with. and sprite pushes out filament crazy fast and very well in the V2 platform as well. on ebay those bigger box tronxies go for close to $400 that is just plain silly.

ps. was the stock sprite ribbon cable long enough for the tronxy frame?

pps. and that, for sprite - seems to be what my unit needs, after calibration tryouts:

#define DEFAULT_AXIS_STEPS_PER_UNIT { 80, 80, 405.5, 424.9 }

I'm looking at a Libre Le Potato board so that I can use the GPIO to run relays to turn the printer on/off and eventually enclosure heaters.and if you still did not get to octoprint - this box was on sale with an additional $5 coupon, i got another one for $30 shiped. cannot beat it.

Amazon product ASIN B0B461KB7VView: https://www.amazon.com/gp/product/B0B461KB7V

then follow this tutorial - it worked flawlessly for me. the only trick is to get a correct t95 box. i did not do klipper, though, do not see any need for it with new marlin.

and should work with this camera:

Tutorial: T95 Mini TV Box Klipper Install

The T95 Mini is an android TV box. Be careful when sourcing one as there are a lot out there that actually use the H616 processor and currently the android tv boxes using this processor don’t…3dpandme.com

Amazon product ASIN B07BPM9SFLView: https://www.amazon.com/gp/product/B07BPM9SFL