-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sheered off my Dan Wesson scope base screws today

- Thread starter DW357

- Start date

That’s what DW supplied lol. What size/type of screws are these anyway? And where can I get grade 8?

They are common and cab found in Lowes, Ace, etc. even allen heads

.

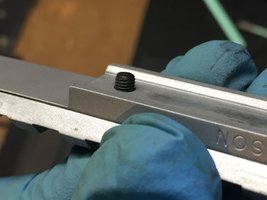

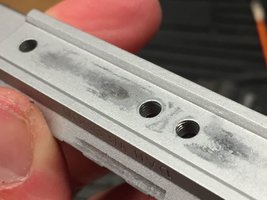

Good question. I think one issue is that the screws aren’t long enough. This is all that is grabbing in the threaded holes in the shroud! They aren’t even close to reaching the end of the threads!is all the shear force on the screws?

is there a way the mount could be installed to take the force and not the screws?

Hopefully I can find some longer and better quality screws lol.They are common and cab found in Lowes, Ace, etc. even allen heads

.

84ta406

NES Member

If it pulled the threads out I would agree but they sheared off above the threads so that's not the issue. You could go longer of course regardless.Good question. I think one issue is that the screws aren’t long enough. This is all that is grabbing in the threaded holes in the shroud! They aren’t even close to reaching the end of the threads!

View attachment 356183View attachment 356184

If you don't have a left hand bit that's a great method but they are cheap and any shop that does repairs should have a set.

Doesn't look like I had any loctite that I can see. Threads in the holes and on the screws look relatively clean.My only concern with the LH bits was the loctite, if it's too tough or gummed up on the threads it won't work very well. I use the LH bits at work quite a bit but I know for a fact things aren't loctite.

And check out the remaining screw! It’s on its last leg before breaking!

Ahh okay.If it pulled the threads out I would agree but they sheared off above the threads so that's not the issue. You could go longer of course regardless.

Ray suggested grade 8 screws? What’s the best quality screw I could get? Any idea what the size/type of these screws? I don’t even know what to search for without knowing that info lol.

PistolShooter

NES Member

www.mcmaster.com will have exactly what you need

Is that a Warne scope mount? Looks like a Warne to me. I found a spec sheet for the DW 445 supermag, this kit uses a T15 (torx) screw. .128in or 3.27mm.

Here's the link

store.gravelagency.com

store.gravelagency.com

You could always do one of those rib vent mounts instead made by leopold, those are rock-solid, and rare af.

Here's the link

M630G : Warne 1pc Black Gloss Dan Wesson 445 Supermag VH Base

Maxima Multi-Sight System has a proven track record for success. Hugely popular with the Smith & Wesson L, K, & N frame revolvers, the Maxima line has now been expanded to include Ruger’s Redhawk and Blackhawk line of hunting handguns, and the Dan Wesson Large Frame 445 Supermag.A new addition...

You could always do one of those rib vent mounts instead made by leopold, those are rock-solid, and rare af.

PistolShooter

NES Member

Grade 8 is the highest you’ll find at a Home Depot but not the highest. Hard screws are not always the answer anyway since if they are from a crappy supplier that plates them, they become brittle if not baked out afterwards. A good supplier won’t have this problem.

pastera

NES Member

But those screws shouldn't have been in shear - they should have been torqued tight enough for clamping force to stop movement.They look like a 8 or 10-32 screw. Measure them with calipers to be sure. Grade 8 has the highest shear resistance.

Cool thanks. I’ll def measure them. Appreciate the help guys.They look like a 8 or 10-32 screw. Measure them with calipers to be sure. Grade 8 has the highest shear resistance.

Sweeney

NES Member

The scope mounts wasn't clamped well enough allowing it to work the screws in shear. The screws don't like that and surrendered. Install tubular dowels (around the screw holes) to take the shear perhaps.

84ta406

NES Member

Agreed, they had to have been loose. I think the lack of thread locker is to blame.But those screws shouldn't have been in shear - they should have been torqued tight enough for clamping force to stop movement.

Since I think there was little to no loctite I really think they became loose and the recoil killed them. If they were kept snug, I don’t think they would sheer like that?Those screws were loose - the clamping force should keep the mount from moving.

Look up the proper torque for the screw size (lubricated) and use removable thread locker.

Once these screws are out, I’m dumping as much blue loctite in as I can lol. As much as I want to use red loctite that seems to risky if I ever want to remove the scope base lol.Agreed, they had to have been loose. I think the lack of thread locker is to blame.

No it’s a factory Dan Wesson mount.Is that a Warne scope mount? Looks like a Warne to me. I found a spec sheet for the DW 445 supermag, this kit uses a T15 (torx) screw. .128in or 3.27mm.

Here's the link

M630G : Warne 1pc Black Gloss Dan Wesson 445 Supermag VH Base

Maxima Multi-Sight System has a proven track record for success. Hugely popular with the Smith & Wesson L, K, & N frame revolvers, the Maxima line has now been expanded to include Ruger’s Redhawk and Blackhawk line of hunting handguns, and the Dan Wesson Large Frame 445 Supermag.A new addition...store.gravelagency.com

You could always do one of those rib vent mounts instead made by leopold, those are rock-solid, and rare af.

I’ve tried the clamp on mounts on my DW 357 and they sucked. Kept breaking loose and marred the shit out of the shroud. No way they would handle 44 mag.

Currently Unavailable | CZ-USA

Another trick is to get someone who is REAL GOOD with a TIG welder (AND ONLY TIG !!!) to build up the screws until you have something to grab onto

www.instructables.com

www.instructables.com

Removing a Broken Bolt or Stud With TIG

Removing a Broken Bolt or Stud With TIG: Often when a bolt or stud breaks off, it breaks with a little bit protruding above the material it's threaded into. In this situation, it is sometimes possible to use a pair of vice grips or such, to facilitate the removal of the bolt. More times th…

I think you’re right.The scope mounts wasn't clamped well enough allowing it to work the screws in shear. The screws don't like that and surrendered.

Thanks. Looks like it may be these. But I’ll have to measure to confirm.www.mcmaster.com will have exactly what you need

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

That’s what DW supplied lol. What size/type of screws are these anyway? And where can I get grade 8?

6 or 8 -32, but someone already mentioned that.

Look for a stainless alternative to anything thats available at lowes or h.d. I've snapped their "grade 8" stuff with little effort.

oldguy68

NES Member

You said you didn't use any Locktite on those screws.

That will make it easier and is a good thing in there removal.

They should spin freely or with a little ease to remove them.

The threads on the revolver should be fine as the screw heads just snapped off.

You didn't strip out or cross thread them.

So it's just a matter of turning what's left out.

Buy better quality screws and use a little blue Locktite.

Don't over do it. You don't need a lot of Locktite to hold them.

Just clean the screw holes and use a little alcohol to degrease the threads before you apply the Locktite to the new screws.

I've snapped bolt heads off and just spun the threaded part left over out with ease.

I still wouldn't risk it on such a nice revolver and would just wait and have it done right.

That will make it easier and is a good thing in there removal.

They should spin freely or with a little ease to remove them.

The threads on the revolver should be fine as the screw heads just snapped off.

You didn't strip out or cross thread them.

So it's just a matter of turning what's left out.

Buy better quality screws and use a little blue Locktite.

Don't over do it. You don't need a lot of Locktite to hold them.

Just clean the screw holes and use a little alcohol to degrease the threads before you apply the Locktite to the new screws.

I've snapped bolt heads off and just spun the threaded part left over out with ease.

I still wouldn't risk it on such a nice revolver and would just wait and have it done right.

Last edited:

Gun broken, no good to you. Me buy for $50, make wall hanger.

6 or 8 -32, but someone already mentioned that.

Look for a stainless alternative to anything thats available at lowes or h.d. I've snapped their "grade 8" stuff with little effort.

It appears they’re 6-48 screws. DW used Weigand scope mounts initially and in the product description it says you need to drill and tap 3 6-48 holes.They look like a 8 or 10-32 screw. Measure them with calipers to be sure. Grade 8 has the highest shear resistance.

I found the exact screws. Flat Head Type D Screw 5/16 in. 6-48.

Amazon product ASIN B07J9HL4MMView: https://www.amazon.com/Numrich-Flat-Head-Screw-Thread/dp/B07J9HL4MM

Now just need to find them in a higher grade. Could also use a torx head as someone else suggested.

i bought this kit years ago to replace the straight slotted and phillips screws on alot of my stuff.Hopefully I can find some longer and better quality screws lol.

BROWNELLS TORX HEAD SCOPE RING & BASE SCREWS | Brownells

A TORX head lets you set a screw down tight without the bit slipping and damaging the screw slot. They give your work a clean, finished appearance. T-10 gives you plenty of additional wall thickness where the head joins the shank; T-15 has a large...

Dont use green.You said you didn't use any Locktite on those screws.

That will make it easier and is a good thing in there removal.

They should spin freely or with a little ease to remove them.

The threads on the revolver should be fine as the screw heads just snapped off.

You didn't strip out or cross thread them.

So it's just a matter of turning what left out.

Buy better quality screws and use a little green or blue Locktite.

Don't over do it. You don't need a lot of Locktite to hold them.

Just clean the screw holes and use a little alcohol to degrease the threads before you apply the Locktite to the new screws.

I've snapped bolt heads off and just spun the threaded part left over out with ease.

I still wouldn't risk it on such a nice revolver and would just wait and have it done right.

Loctite 222 is a good choice for small screws.

sometimes you need to use the primer on inactive metals.

Share: