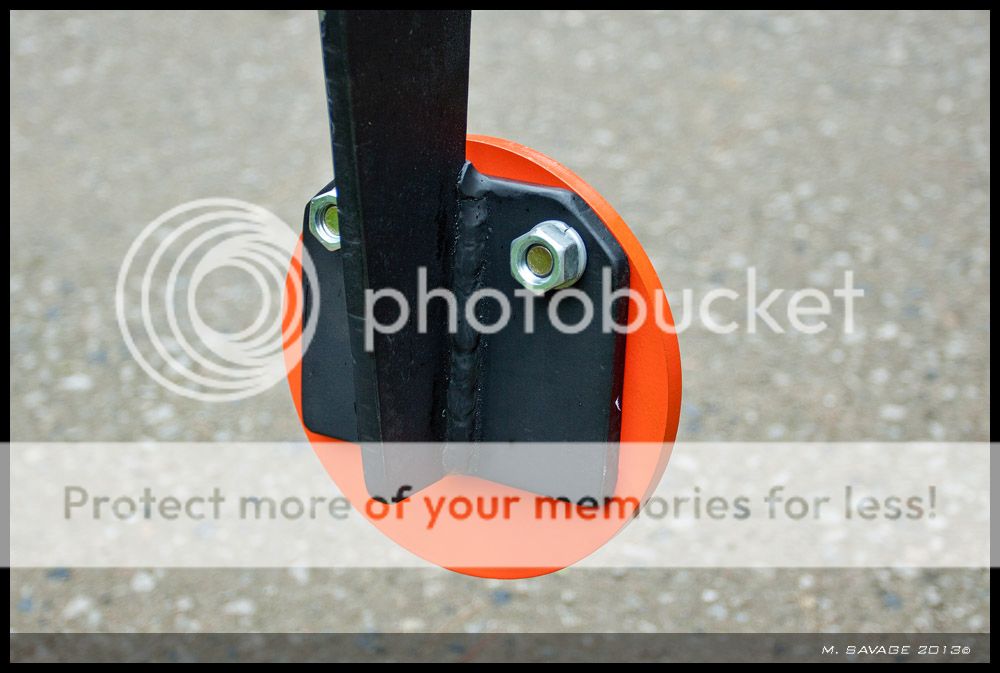

So I've had this Evil Roy target from Action Targets for over 3 years and I've had to replace the target head twice due to a cracked weld. I originally bought the target from Brownells and they only offer the AR500 steel which lasted maybe a little over a year before the target head fell off from the weld cracking. I call up Action Targets and they said they would ship me a AR550 target if I paid the price difference between the AR500 and AR550 which was $20, I had no issues with that so I paid the $20 and they shipped me the new target. Now about 2 years later the AR550 steel target weld is now severely cracked and the target is going to fall off with a few hundred more shots of 7.62x39.

View attachment 101370View attachment 101371View attachment 101372

I shoot at it with rifle, only 7.62x39 no .223 or 5.56 at 120 yards. They recommend 100+ yards for velocities 3,000 fps and higher. So I'm definitely below the velocity and beyond the minimum distance. In the 2 years I've had the AR550 it's certainly been shot at thousands of times with x39 and various pistol calibers (9mm, 38/.357 mag) which are nothing compared to x39. The stand is chewed up a bit from when I first got my SKS and was getting it sighted in lol.

So now I called them up and the guy told me it's beyond the 1 year warranty so he can't replace it free of charge which I didn't know they only had a 1 year warranty but I know now. He told me "I'm able to give you a pretty steep discount on a replacement. Replacement plates run $95 but I can get you one for $42.53 to cover the cost of fabrication."

I emailed him back saying I'll take the steep discount and also asked if the welds are suppose to crack after 1-2 years of use? I haven't heard back from him yet as it was late in the day that I contacted them.

They're a top notch company but I was curious if anyone else has the same target and has encountered the same issue? Or if others have similar AR550 targets that are welded to something. I've dealt with this twice and I thought for what you pay for the target (over $200 with shipping if you buy directly from them or about $125 from Brownells shipped), that it should be a little more durable but maybe my expectations are too high.

http://store.actiontarget.com/evilroyline/evil-roy-practice-target.html

They're going to have free shipping on all of their targets during the NRA annual meeting this weekend (4/25-4/27 only), coupon code SHIPFREE

View attachment 101370View attachment 101371View attachment 101372

I shoot at it with rifle, only 7.62x39 no .223 or 5.56 at 120 yards. They recommend 100+ yards for velocities 3,000 fps and higher. So I'm definitely below the velocity and beyond the minimum distance. In the 2 years I've had the AR550 it's certainly been shot at thousands of times with x39 and various pistol calibers (9mm, 38/.357 mag) which are nothing compared to x39. The stand is chewed up a bit from when I first got my SKS and was getting it sighted in lol.

So now I called them up and the guy told me it's beyond the 1 year warranty so he can't replace it free of charge which I didn't know they only had a 1 year warranty but I know now. He told me "I'm able to give you a pretty steep discount on a replacement. Replacement plates run $95 but I can get you one for $42.53 to cover the cost of fabrication."

I emailed him back saying I'll take the steep discount and also asked if the welds are suppose to crack after 1-2 years of use? I haven't heard back from him yet as it was late in the day that I contacted them.

They're a top notch company but I was curious if anyone else has the same target and has encountered the same issue? Or if others have similar AR550 targets that are welded to something. I've dealt with this twice and I thought for what you pay for the target (over $200 with shipping if you buy directly from them or about $125 from Brownells shipped), that it should be a little more durable but maybe my expectations are too high.

http://store.actiontarget.com/evilroyline/evil-roy-practice-target.html

They're going to have free shipping on all of their targets during the NRA annual meeting this weekend (4/25-4/27 only), coupon code SHIPFREE

Last edited: