-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

-

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

80% AR build/build party info

- Thread starter 7.62x39

- Start date

This will be my first 80% AR build, but I'm pretty handy and I've read through a lot of the instructions on "how to" - and I will do so again.

I don't have a place or press/mill - but I've kicked in towards a jig - and it would be great to get together and talk guns/revolution & chili lol

Maybe we can put together a list of bits that we will need (and ones to avoid) so we are all prepared?

-- Billerica/Chelmsford area but willing to travel

I don't have a place or press/mill - but I've kicked in towards a jig - and it would be great to get together and talk guns/revolution & chili lol

Maybe we can put together a list of bits that we will need (and ones to avoid) so we are all prepared?

-- Billerica/Chelmsford area but willing to travel

Believe that once it's capable of being fired, the clock starts ticking on doing your FA10 form (or whatever that crap is)... So, once it's a complete rifle/firearm, then you need to get moving on the paperwork. Otherwise, you're good.

Check the laws to be 100% sure on that though.

Paperwork

![ROFL [rofl] [rofl]](/xen/styles/default/xenforo/smilies.vb/013.gif) I'll get right on that. Just like I'm putting serial numbers on them.

I'll get right on that. Just like I'm putting serial numbers on them. Being stripped or not in this instance doesn't make much sense seeing stripped lowers require a fa10. To me if they treat a complete and stripped lower as the firearm (from a manufacturer) I don't see how a completed stripped 80 wouldn't be classified as evil by this state.

BlackwaterFence

NES Member

- Joined

- Oct 27, 2011

- Messages

- 1,268

- Likes

- 1,388

In for a south shore build

I don't have access to a shop, but have a bench top drill press

However, a milling machine is what we should be looking for

I don't have access to a shop, but have a bench top drill press

However, a milling machine is what we should be looking for

Golddiggie

NES Member

I've created a thread for the build party at my place...

NEED at least one person with the AR15 jig and one with the AR10 jig. After that, there will be 8 more 'people slots' available. If there's a high enough interest level in meeting up here, we could do a rotation, or a second build day (or third). Just figure that 10 at a time (not including me) is a good level.

NEED at least one person with the AR15 jig and one with the AR10 jig. After that, there will be 8 more 'people slots' available. If there's a high enough interest level in meeting up here, we could do a rotation, or a second build day (or third). Just figure that 10 at a time (not including me) is a good level.

Being stripped or not in this instance doesn't make much sense seeing stripped lowers require a fa10. To me if they treat a complete and stripped lower as the firearm (from a manufacturer) I don't see how a completed stripped 80 wouldn't be classified as evil by this state.

Stripped lowers do NOT require FA10. They are transferred to you from your FFL on a 4473 because the Feds consider it a firearm. MA does not, no FA-10 until it is completely assembled.

So the Feds say it is. The state says it isn't. What's the state consider a 80% the way it sits and when you "manufacture" your own. Seems to be completely ridiculous. So your saying that mass does not require a ltc to purchase or manufacture your own?

Golddiggie

NES Member

So the Feds say it is. The state says it isn't. What's the state consider a 80% the way it sits and when you "manufacture" your own. Seems to be completely ridiculous. So your saying that mass does not require a ltc to purchase or manufacture your own?

Pretty much. Believe the fed's don't care either (either finishing the 80%, a 0%, or machining your own from plans). You just can't sell/give away the lower you finish/make since it has no serial number on it. It's great for those with the skills, knowledge, tools, desire.

So the Feds say it is. The state says it isn't. What's the state consider a 80% the way it sits and when you "manufacture" your own. Seems to be completely ridiculous. So your saying that mass does not require a ltc to purchase or manufacture your own?

The 4473 requires a NICS check so you have to have an ltc. You can mfg your own receiver but must have ltc to possess the assembled rifle.

Golddiggie

NES Member

The 4473 requires a NICS check so you have to have an ltc. You can mfg your own receiver but must have ltc to possess the assembled rifle.

If it wasn't for MA requiring the LTC to have the firearm, you wouldn't need to do anything. Such as in NH or Maine (I believe with Maine too, could be with Vermont as well). With long guns especially, pistols are a bit different.

The 4473 requires a NICS check so you have to have an ltc. You can mfg your own receiver but must have ltc to possess the assembled rifle.

Thanks for the laugh. It never ceases to amaze me how retarded this state is. So in reality someone without an ltc in mass could buy a stripped lower (passing nics) and then if they wanted to assemble it they could and just got around the ltc law. Ridiculous.

Thanks for the laugh. It never ceases to amaze me how retarded this state is. So in reality someone without an ltc in mass could buy a stripped lower (passing nics) and then if they wanted to assemble it they could and just got around the ltc law. Ridiculous.

You could buy a stripped lower FTF without nics, if you buy it from an FFL, you will have to pass nics.

I think we've wasted enough space on this subject in this thread. This has been covered numerous times in the MA laws forum, any further discussion on this should be in that forum, that's what it's for. Let's keep this thread on track.

Golddiggie

NES Member

Has anyone reached out to nearby machine shops with a mill that might be willing to do this?

I have, to one not far from where I am. Issue is, he's rather busy now. Plus, if we want to do this on the weekend, it could get tricky. Looks like one of the people signed up for my build party has a mini mill. That should do the job, after we get the majority out with my drill press and such. Just need to have people with confirmed jigs sign up (one AR15 and one AR10 is needed) for this.

I'm also willing to host a second party (maybe even a third) for people that can't make it to the first one (or second). As long as I'm still in the area, and jigs are brought, I'll host.

Willing to host in westfield. I'm on the fence about a jig but due to the lack of feedback from western ma guys I'm leaning towards buying one. I should have access to 1-2 mills and have been looking in to picking one up. I have a 1100sq ft garage/ workshop with plenty of room. So it's really up to western mass guys.

If you've got access to a mill, the jig is not needed at all. Would be like putting training wheels on a Tour de France race bike.

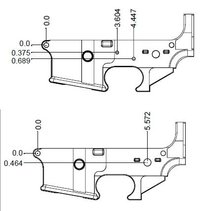

Here's the measurements from chapter 3 of the "rav-vin" tutorial. Similar info is there for the FCG pocket.

Attachments

Golddiggie

NES Member

to Golddiggie! I am in for this build party. I have 1 AR-10 and 3 AR-15 lowers coming. Contributed to a 15 jig but not a 10 jig yet. Anyone coming with a 10 jig? Would be willing to split the cost if you do.

It was hard enough for me to allocate the funds for the lowers, never mind spend on the jigs. I'm between jobs at the moment, so money is really tight. I have some things posted in the classifieds, which if they sell soon enough I could be in on a jig (or part of one).

I have the blueprints (not to scale) for the AR10 already printed out. So if we get the end mill here, we might not need the jig for that. Depending on what else needs to be done beside the FCG area.

BTW, does anyone have a way to mark the outside of the lowers? Something to place information outside the mag well (akin to what the manufacturers do) and/or to put messages where the safety selector goes.

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif) That way we can have something more unique on the lowers.

That way we can have something more unique on the lowers.

Last edited:

in the boston area. will be getting either 2 AR15 lowers, or a 10 and 15 once finances settle. I will be in need of hand holding on this one. I have machining experience, but I dont want to f this one up.

For those concerned with having the safety positions marked, I have a simple suggestion.

Place a small divot with a drill bit or burr at both locations. Color the safe position with a white dot and the fire position with a red dot. Many firearms are marked in such a way and would save having to get onto the whole engraving/laser etching thing.

Place a small divot with a drill bit or burr at both locations. Color the safe position with a white dot and the fire position with a red dot. Many firearms are marked in such a way and would save having to get onto the whole engraving/laser etching thing.

Has anyone reached out to nearby machine shops with a mill that might be willing to do this?

You start to get Into the legality of "manufacturing" a firearm at a business, I guess it can be a shady area.

---CNC machinist/programmer for 10+ years.I wish I could just walk everyone through my shop and finish them in a couple operations.

Golddiggie

NES Member

I'll have to look for that one... If you have the link handy, could you PM it to me??GoldDiggie : someone mentioned laser etching and there's a Karma from WI Laser, so maybe they can do a design and the markings for safety/etc?

That wouldn't be as cool though. Sure, it would do the job, but there's something cathartic about having your own, more unique, version of 'safe' 'fire' on there.For those concerned with having the safety positions marked, I have a simple suggestion.

Place a small divot with a drill bit or burr at both locations. Color the safe position with a white dot and the fire position with a red dot. Many firearms are marked in such a way and would save having to get onto the whole engraving/laser etching thing.

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)

It looks like we'll have a small mill at my build party (if it goes well). So, we could use that to finish the FCG area once most has been removed via drill press.You start to get Into the legality of "manufacturing" a firearm at a business, I guess it can be a shady area.

---CNC machinist/programmer for 10+ years.I wish I could just walk everyone through my shop and finish them in a couple operations.

I need to find the CAD files for AR10 (.308) magazines. I have them for the AR15 (.223/5.56) but want the others.

These threads keep getting way off topic. Can anyone confirm if there will be a build party in the Worcester area? I'm ready to place my order and pay up, I just need to know if I need my own jig or if I'll be contributing to a community one. I can bring beer, dancing girls, brandy new 1/4x28 taps, and drill bits, or end mills if needed.

How far out would the actual builds be? If I could plan ahead I could possibly host a small build in Southern NH. I have a full sized mill and I'm assuming everything we'd need to do it. I don't have a DRO but if people do these with a drill press, I can't image we couldn't figure it out with a little ingenuity.

Let me read that feeler to make sure I have everything we'd need. I have a bunch of endmills and bits.

My shop ain't big, though...I couldn't host more than a few people.

Here's my mill:

Let me read that feeler to make sure I have everything we'd need. I have a bunch of endmills and bits.

My shop ain't big, though...I couldn't host more than a few people.

Here's my mill:

I have a bridgeport mill An a couple lathes, shapers ect..in my home basement shop, I would be willing to help a few people out, I am in Rehoboth, That being said, I realy don't know what this thread is in reguards to so it looks like I will be going green in a few min.

I have a bridgeport mill An a couple lathes, shapers ect..in my home basement shop, I would be willing to help a few people out, I am in Rehoboth, That being said, I realy don't know what this thread is in reguards to so it looks like I will be going green in a few min.

Welcome aboard... Thanks for going Green.

PM sent.

Share: