-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

-

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

8/44 CMP Range report and big problem

- Thread starter majspud

- Start date

Missing something. Something is binding. That chrome oprod tip isn't even dirty! Re do the detail strip. Something ain't tracking right?

Maj. That rusty colored goop on barrel and lock threads came from somewhere? How does the oprod function with out the gas. Cylinder on it.

Maj. That rusty colored goop on barrel and lock threads came from somewhere? How does the oprod function with out the gas. Cylinder on it.

Last edited:

I hear ya. It looks like the op-rod may be sitting high in the raceway in that pic, but it's really hard to tell.

Spud, do the "tilt test" and let us know if you get any binding.

M1 Garand Tilt Test - YouTube

Spud, do the "tilt test" and let us know if you get any binding.

The rifle should only have the bolt, gas cylinder, hand-guards and op-rod installed. Remove any grease that may be present. When you tilt the rifle up and down at approximately 60 degrease the bolt and op-rod should open and close under its own weight. If the rifle fails this test inspect for area's where the op-rod is rubbing. Repeat this test with the stock installed minus the trigger assembly. To help determine if an area is binding, apply a thin coat of grease to the op-rod in the suspect area. Repeat the test and look for an indication of the grease being rubbed from the op-rod onto the part that is causing the binding.

M1 Garand Tilt Test - YouTube

Also look straight down from above the reciever. You can some times see a bow in the op rod. It can be tough to pick up. If you have another garand to compare to it will show up better. Also check for anything that might have found its way anyway near the travel of the op rod.

Maj. Don't you have a missing lower band pin? At my work missing parts end up in the worst places?

Maj. Don't you have a missing lower band pin? At my work missing parts end up in the worst places?

Oh, it's got better than a bow - it's an "S".

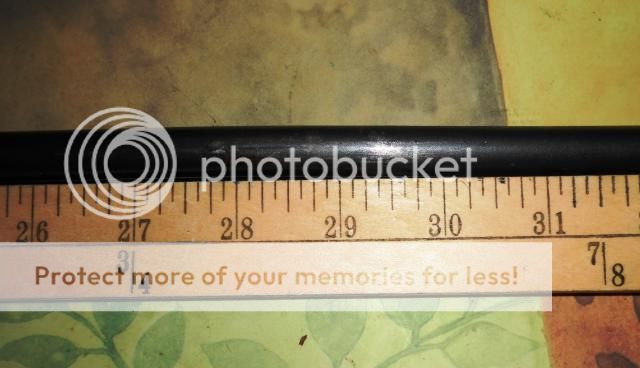

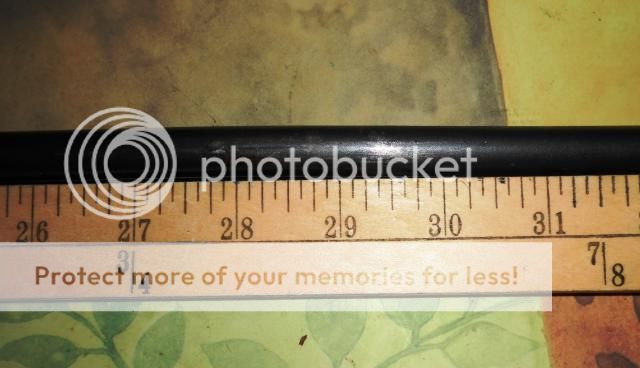

Went downstairs and took out both my Garands and began swapping parts. Cut the story short, when I pulled the field grade op rod, I felt the problem before I saw it. Holding it up to the light like I used to do with my arrows, I found it was bent in two places.

The spring measured 19-7/8 - that's short if I remember.

Here is a yard stick for a straight edge comparison:

PM

Went downstairs and took out both my Garands and began swapping parts. Cut the story short, when I pulled the field grade op rod, I felt the problem before I saw it. Holding it up to the light like I used to do with my arrows, I found it was bent in two places.

The spring measured 19-7/8 - that's short if I remember.

Here is a yard stick for a straight edge comparison:

PM

Throw in an Orion7 spring. It's a good idea to get their M1 spring KIT as well, and throw it in the range bag.

Maybe we could get a group buy going with Orion7 with all the people buying garands?

Turns out one spring is less than their minimum order of $20. We would need at least 2. Price goes down as well.

1=$8, 2-4=$7.50, 5+=$7.

T

Oh, it's got better than a bow - it's an "S".

Went downstairs and took out both my Garands and began swapping parts. Cut the story short, when I pulled the field grade op rod, I felt the problem before I saw it. Holding it up to the light like I used to do with my arrows, I found it was bent in two places.

The spring measured 19-7/8 - that's short if I remember.

Here is a yard stick for a straight edge comparison:

PM

I dont think your really checking that correctly, by design op rods have bends. From the pics looks like the natural bends by design ?

try the tilt test, link in previous post.

Is the brown stuff on the bottom of the barrel your grease? Also I noticed no grease on your front handgard metal? I put a touch of grease on the metal in the channel.

Last edited:

group by on the springs is going to be tough, unless we all agree to meet some where, I doubt they will drop ship each individual spring(s)? If we can get enough people to say meet at one of the cmp shoots/clinics/matches it might be worth while.....PS dont get just the op spring get the spring kit. Your garand will love it. I swear all new springs reduce recoil and improve accuracy(all in my head) but does do wonders for function.Turns out one spring is less than their minimum order of $20. We would need at least 2. Price goes down as well.

1=$8, 2-4=$7.50, 5+=$7.

T

also Majspud: check the follower rod. It may be bent also and binding in the oprod? Spring length is 19" min free unloaded free length....check to be sure nothing is jammed up inside the op rod spring tube?

Find that hand guard pin yet?......dont know but I feel like this ended up somewhere it shouldnt have?

Last edited:

OP rods are tough to properly gauge due to the multiple bends on the darn things. How does the op rod tab that runs in the receiver track look?

+1 to the follower rod inspection. A bent follower rod will do funny things to an M1.

Maj, when you say that the gas cylinder has significant scratching, to what part are you referring? Maybe it was just the pictures, but I didn't see anything egregious. The rear lower part of the interior of the gas cylinder is machined down at a different angle than the rest of it. It's like a subtle ramp.

Whatever it is, keep us posted.

+1 to the follower rod inspection. A bent follower rod will do funny things to an M1.

Maj, when you say that the gas cylinder has significant scratching, to what part are you referring? Maybe it was just the pictures, but I didn't see anything egregious. The rear lower part of the interior of the gas cylinder is machined down at a different angle than the rest of it. It's like a subtle ramp.

Whatever it is, keep us posted.

That sucks....well lets see what cmp says. To bad you didn't pick up on that on first inspection....

Not to bash cmp but maybe to many unseasonedvolenteers in the shop right now.

As I mentioned about my HRA service grade. It is by far the most worn out finish of 4 SG rifles I have. IF it didn't have nice tight locking up stock and a LMR barrel with teme readings of -2 and shot as well as it did for first 40 rounds. I would be a bit disappointed. I have only 1 FG and it had its share of problems cmp did help me with a few small parts and set up a call back with armorial @ cmp. I buy these to shoot so looks ain't a issue with me. Cmp is still the best deal going.

Majspud just think if you bought that rifle local it would most likely cost you 800+ and if you brought it back saying the oprod is bent what do you think would happen.

Cmp is @ about 3 days for me on return emails. I have had some order issues. CMP has always been 100% with me.

What gets me is you had it functioning in the beginning AND you had a missing part..........I'm inclined to think that friken pin found its way into something? That would be driving me crazy right now. I would be going over every inch of that rifle looking for fresh gouges on any metal parts. Along with buying a big magnet and scanning every inch of space where you did the work to find that pin! Just so I know it didn't end up in the gun!.

Not to bash cmp but maybe to many unseasonedvolenteers in the shop right now.

As I mentioned about my HRA service grade. It is by far the most worn out finish of 4 SG rifles I have. IF it didn't have nice tight locking up stock and a LMR barrel with teme readings of -2 and shot as well as it did for first 40 rounds. I would be a bit disappointed. I have only 1 FG and it had its share of problems cmp did help me with a few small parts and set up a call back with armorial @ cmp. I buy these to shoot so looks ain't a issue with me. Cmp is still the best deal going.

Majspud just think if you bought that rifle local it would most likely cost you 800+ and if you brought it back saying the oprod is bent what do you think would happen.

Cmp is @ about 3 days for me on return emails. I have had some order issues. CMP has always been 100% with me.

What gets me is you had it functioning in the beginning AND you had a missing part..........I'm inclined to think that friken pin found its way into something? That would be driving me crazy right now. I would be going over every inch of that rifle looking for fresh gouges on any metal parts. Along with buying a big magnet and scanning every inch of space where you did the work to find that pin! Just so I know it didn't end up in the gun!.

Last edited:

Just to add....I have 2 op rods I'm considering sending out to Jim swartz for repair and over haul. Only guy known with standing Rep of knowing what he is doing ahem it comes to "fixing" op rods. I have rebent one myself on a real beater by friend has. Wasn't easy....took a long time of trial and error....easier to send to those that know.

All parts were separated save the TG assembly. The cylinder was tough to put on in the first place, and the op rod will cycle. After cleaning, the op rod will cycle. It hangs up when the first bend hits the mouth of the cylinder. If they only fire one or two test rounds, it would have passed. I think it was my 6th round I had to help the bolt forward. Then things got worse as it got hotter.

I assume CMP will ask for it back to replace the op-rod.

T

I assume CMP will ask for it back to replace the op-rod.

T

To me it sounds as if something was not sitting correctly after reassembly. Getting worse with heat leads me to think expansion from heat and lack of lube? Have you installed the op rod from your other rifle.

What would be bugging me right now is was it bent or did I bend it.......arrgghh. I think I'm more frustrated than you!

I would swap op rods and see if problem is still there....I have read a few articles of HRA post war op rods not playing well with wwII era rifles?

What would be bugging me right now is was it bent or did I bend it.......arrgghh. I think I'm more frustrated than you!

I would swap op rods and see if problem is still there....I have read a few articles of HRA post war op rods not playing well with wwII era rifles?

I took some more pics with the op rod in. I used no flash. I cocked the action and released the bolt; it stopped where it was from the friction entering the gas cylinder. Note the loss of blue on the side at the beginning, and at entering the cylinder. 15 rounds could not have caused that. There was also surface rust inside the first two inches or so inside the mouth of the op-rod.

T

T

I would swap op rods and see if problem is still there....I have read a few articles of HRA post war op rods not playing well with wwII era rifles?

Really? Never heard that before. My recent SA FG 3.44 Jan 1945 has an HRA op rod. The op rod is definitely "field grade" so I haven't swapped it for the SA op rod on my HRA SG.

Really? Never heard that before. My recent SA FG 3.44 Jan 1945 has an HRA op rod. The op rod is definitely "field grade" so I haven't swapped it for the SA op rod on my HRA SG.

Been trying to find the post on cmp forum. It came up on a search I did on google. It was berried deep. The general consensus was the Winchester and early sa where well worn vs the not so worn HRA and a a bit tighter specs of the later production parts? I have one rifle that is dedicated to parts swamping. Less the worn barrel and bent op rod all the parts are good. So if I have part in question on another rifle I will swap it out.

Just go to the Concord show and pick up the parts you need. Its easier than mailing away or trying to get others to buy parts to offset your $20 minimum. Or buy some other parts as well and get your order over 20 bucks.

What grade rifle was it? When you read the description of the grades some do include rust etc.

What grade rifle was it? When you read the description of the grades some do include rust etc.

Was in email contact with the lead armorer at CMP today; Phil New. I was at work with a different computer when he said he wasn't getting the pics in my emails. So in a fit if inspiration, I sent him the link to same post on Gun Boards. As a result, customer service is sending me a label for exchange of the op-rod; I assume he must have agreed with our conclusions there. I called to clarify - but I called at 4:31 and missed them - that I assume I'm sending the whole rifle so it can be fitted properly and not just the op-rod.

T

8/44 CMP Range report and big problem

T

8/44 CMP Range report and big problem

Phil new is great to work with. If you and Phil are confident it is a bent rod then that's what cmp will do. Thing is though I'm not so sure they have another rifle to send you either......hope they over night it.

He looked at my concurrent Gun Boards post (link in post #50) and just said customer service was sending me a return slip for the op-rod only. I emailed him back as I was concerned about fine tuning it and should I send the rifle too. He didn't explain, but said the return was for the op-rod only. The GB opinion is that any properly tuned op-rod will fit any Garand. My results and pics showed an op-rod obviously out of tune and binding.

T

T

Just to assure you I have installed all my op rods onto one rifle seeing if anyone worked better, they all worked fine...but would you know the bent op rod refused to work in any of the garands......

So are they sending out the replacement and you return the bent one. Or are they just sending you a return tag ?

So are they sending out the replacement and you return the bent one. Or are they just sending you a return tag ?

They're sending a shipping label (tag?), I bought a shipping box, and I send the op-rod back. I presume it is to be replaced, but maybe they'll knock it back into spec instead - Phil didn't specify.

T

T

They will send you another one.....I cant see them taking time to bend tweek fit and test a op rod. I'm still tossed on just buying another to replace axbent op I have or ship them out to be fixed by jimxswartz?

While you wait Majspud. Order a Orion seven spring tune up kit.

While you wait Majspud. Order a Orion seven spring tune up kit.

Last edited:

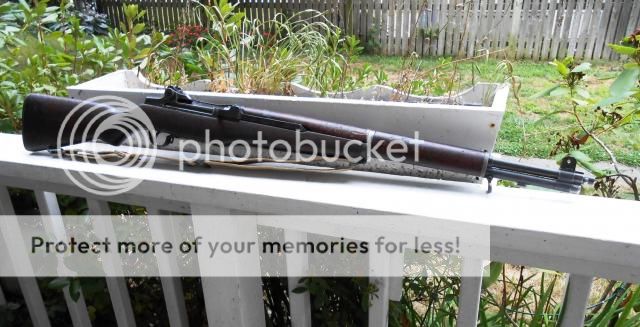

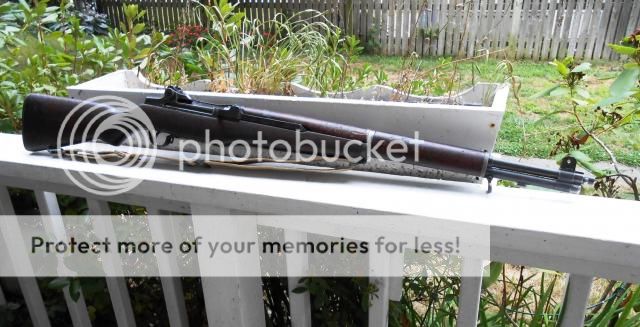

M1 Garand Danish Clone.

The last of my parts arrived to build up my new CMP M1 as a Danish Clone before CMP's return letter arrived for the defective op-rod. I got a nice Danish sling with clear markings in good shape as well as a 1944 dated Danish Zinc 10 Ore piece to match the receiver date. I only had Phillips heads at home in this size - I'll get a slotted one later. Wondering if I should get it bright as it is to match the coin, or brass as they were for the unit marks.

A crummy afternoon to take pics, a heavy fog is rolling in and stealing the color. The stock degreasing went well and it looks better than the pics show.

Thanks for the look,

T.

The last of my parts arrived to build up my new CMP M1 as a Danish Clone before CMP's return letter arrived for the defective op-rod. I got a nice Danish sling with clear markings in good shape as well as a 1944 dated Danish Zinc 10 Ore piece to match the receiver date. I only had Phillips heads at home in this size - I'll get a slotted one later. Wondering if I should get it bright as it is to match the coin, or brass as they were for the unit marks.

A crummy afternoon to take pics, a heavy fog is rolling in and stealing the color. The stock degreasing went well and it looks better than the pics show.

Thanks for the look,

T.

Last edited:

Share: