Received 57 days from mailing the letter. Looks like I got a SG barrel in a FG wood and metal. Not as nice as my other Garand, but I do like the Park-faded-to-grey patina better than the Greek blue/black finish of the other one.

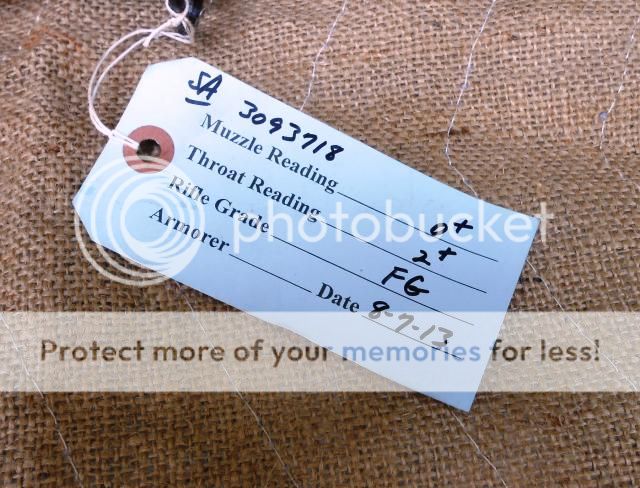

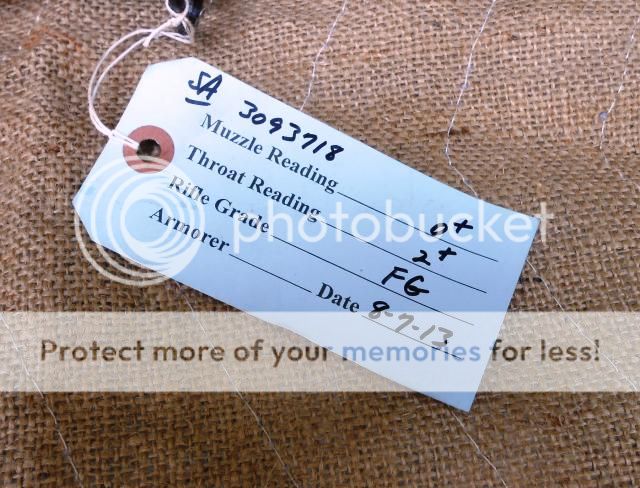

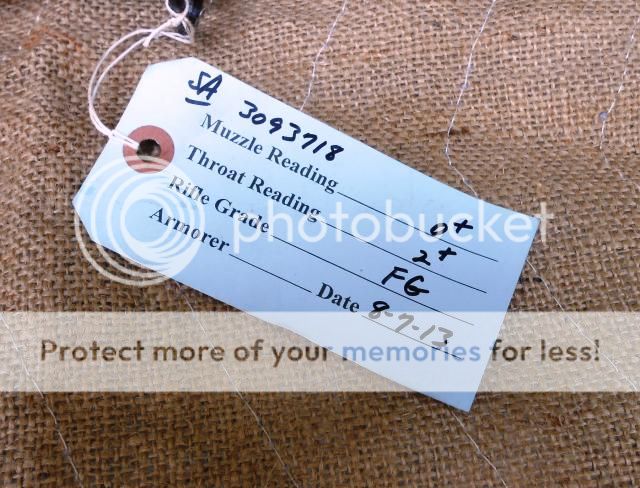

3.09M: August of 1944

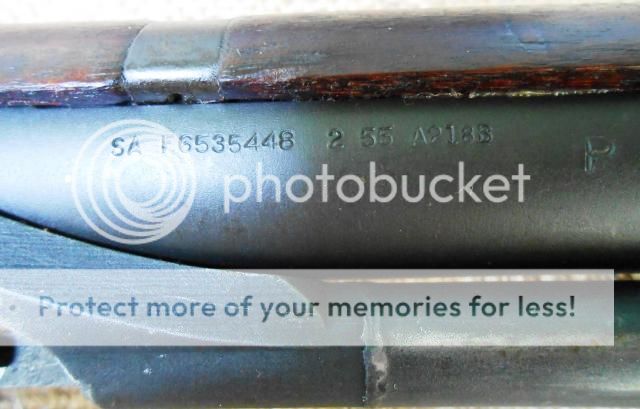

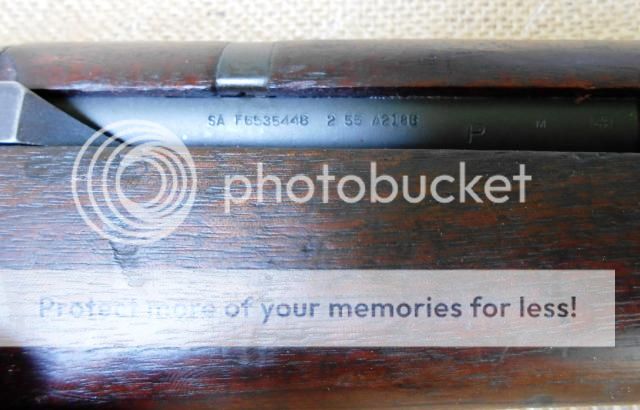

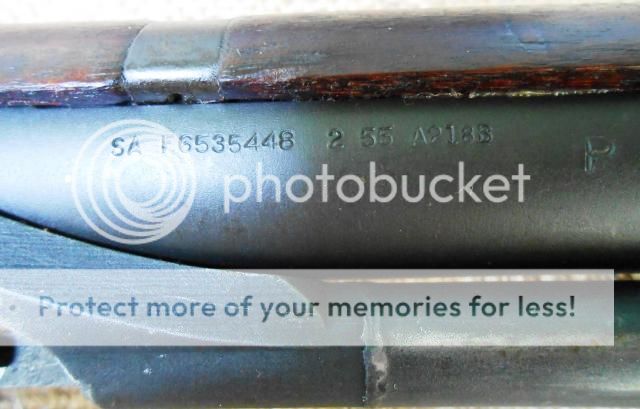

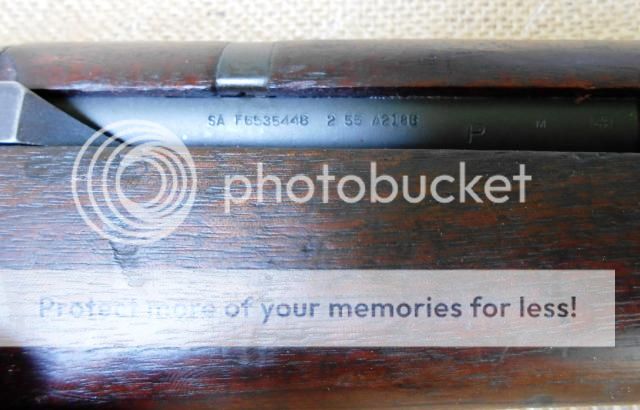

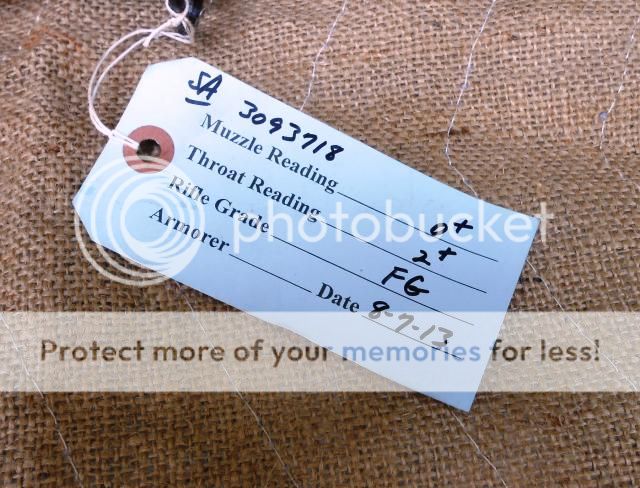

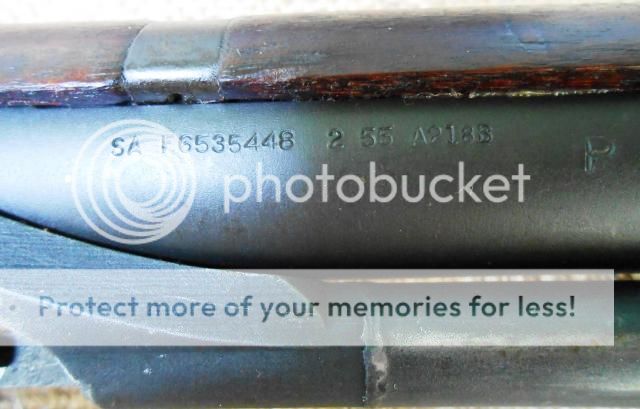

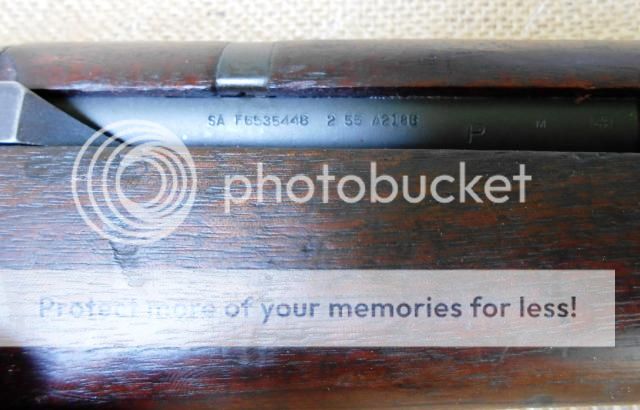

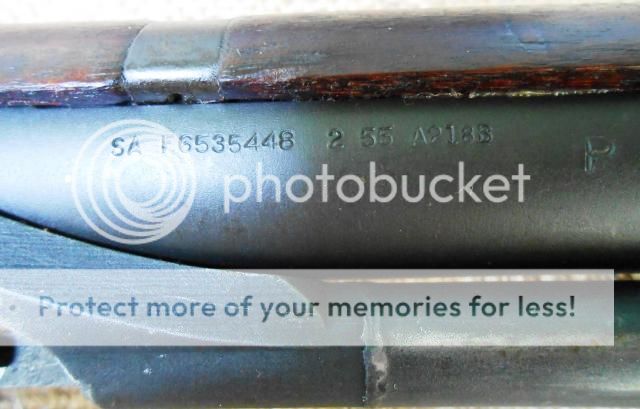

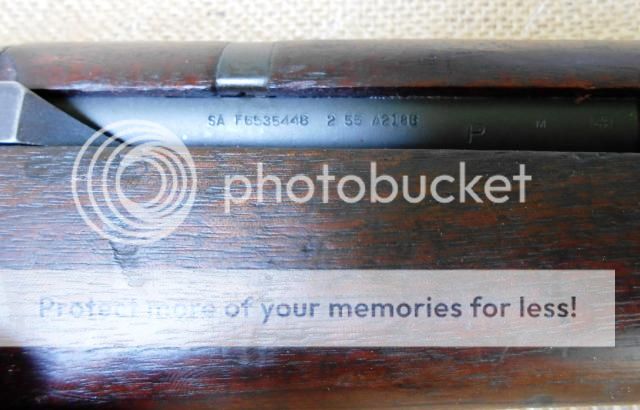

SA: re-barrel 2/1955; ME-0+, TE-2+. Barrel is clean and bright after one bore snake pass. There is a small scratch in a groove about 1-2 inches down. Writing at top of breech under hand-guard is not EP; it faded with CLP. Barely legible - something like FG only/FG oily. Doubt CMP did it, otherwise I'm surprised they let that mangled lower band get through quality control.

Bolt: 6528287-SA over US1 = 1953-1955

Trigger guard: 6528290-SA = 1952-1955

OP rod: HRA - 6535382 = 1953-1956

The lower barrel band left side hole is severely buggered; I had to use the blunt end of a small finishing nail and a hammer to remove the drift pin to the right - but the pin is undamaged and I could remove the band.

Possible original stock; very faint SA/GAW (8/43-3/45), Circle P, Danish pistol grip cut out, and renumber 2785204 on stock keel. If a re-stamp of the original serial number, then the stock mark would still be the same, but date the original action to April of '44. Stock is dark and greasy. Grease under hand guards and butt plate door.

Original string cleaning pull through inside butt plate

Gas nut screw has minimal finish, but locks in at 1 business card. Gas nut bolt has no finish save threads and has a Turk moon on it. Probably get another one with a better finish on it.

I've got the greasy stock and metal parts wrapped in paper towels in a black trash bag in the rear deck of my VW for the last two hours to start de-greasing the stock; no clouds and 86 degrees in the shade. I'll leave it there until Thursday or Friday and give it a couple of turns.

I've got a cheap original web sling on the way from eBay of Korean age: a faint MRT over 1952.

Thanks for looking,

T

3.09M: August of 1944

SA: re-barrel 2/1955; ME-0+, TE-2+. Barrel is clean and bright after one bore snake pass. There is a small scratch in a groove about 1-2 inches down. Writing at top of breech under hand-guard is not EP; it faded with CLP. Barely legible - something like FG only/FG oily. Doubt CMP did it, otherwise I'm surprised they let that mangled lower band get through quality control.

Bolt: 6528287-SA over US1 = 1953-1955

Trigger guard: 6528290-SA = 1952-1955

OP rod: HRA - 6535382 = 1953-1956

The lower barrel band left side hole is severely buggered; I had to use the blunt end of a small finishing nail and a hammer to remove the drift pin to the right - but the pin is undamaged and I could remove the band.

Possible original stock; very faint SA/GAW (8/43-3/45), Circle P, Danish pistol grip cut out, and renumber 2785204 on stock keel. If a re-stamp of the original serial number, then the stock mark would still be the same, but date the original action to April of '44. Stock is dark and greasy. Grease under hand guards and butt plate door.

Original string cleaning pull through inside butt plate

Gas nut screw has minimal finish, but locks in at 1 business card. Gas nut bolt has no finish save threads and has a Turk moon on it. Probably get another one with a better finish on it.

I've got the greasy stock and metal parts wrapped in paper towels in a black trash bag in the rear deck of my VW for the last two hours to start de-greasing the stock; no clouds and 86 degrees in the shade. I'll leave it there until Thursday or Friday and give it a couple of turns.

I've got a cheap original web sling on the way from eBay of Korean age: a faint MRT over 1952.

Thanks for looking,

T

Last edited:

![Crying [crying] [crying]](/xen/styles/default/xenforo/smilies.vb/006.gif)

![Flame [flame] [flame]](/xen/styles/default/xenforo/smilies.vb/032.gif) . I finally had to use a bullet case with locking pliers to hold the ejector down and then a small screw driver to hold the extractor retaining pin down while hitting the extractor with the back of a screw driver. I'm never taking this one down again; it's that tight.

. I finally had to use a bullet case with locking pliers to hold the ejector down and then a small screw driver to hold the extractor retaining pin down while hitting the extractor with the back of a screw driver. I'm never taking this one down again; it's that tight.![Shocked [shocked] [shocked]](/xen/styles/default/xenforo/smilies.vb/007.gif) I can't figure it out I was double careful to put parts in plastic bags so I wouldn't loose anything. In the meanwhile, I snipped off a length of nail and covered it with a little electrical tape and it fit fine for now.

I can't figure it out I was double careful to put parts in plastic bags so I wouldn't loose anything. In the meanwhile, I snipped off a length of nail and covered it with a little electrical tape and it fit fine for now.