impossible to say which brand now, it is gone anyway, that spool. it was not really underextruding before with the original hotend, so, go figure.It looks like under extruding. Possibly due to a partial clog in the nozzle. What brand PLA?

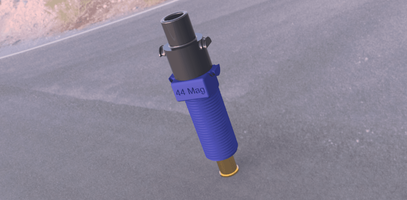

i will try now other spool of blue pla+ - will see if that one will work better.

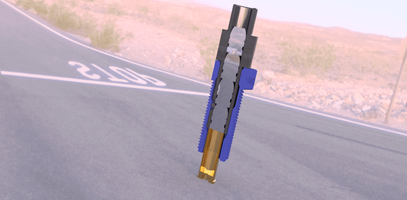

this new sprite pro head is tricky, it takes some time to adjust to its performance. i had to reduce the infill amount 15% to the wall flow, or it was doing the messy pool of goo.

the PC-CF i have dialed in perfectly well now, those prints are just amazing - last one i did in 15hrs that used to be a day and a half before.

other materials will probably take some effort to dial in. i am playing with those FFV5.0 profiles - they all come with default 95% set for extrusion and 4.2mm line width, so, will see if that is the effect. or not. last one - the shot i had shown, had wall extrusion set to 100% - and the concentric crap was of exactly same pattern as on the 95% extrusion profile.

what is good with that sprite pro also - it is really not truly possible to clog it, and if pushed filament by hand down it feels how it flows out free. great design, so much better than the original bowden tube thing.

i was just very surprised to see it on PLA as that superhard PC-CF is way more sensitive to extrusion amounts and immediately shows defects on inconsistent layers.

![ROFL [rofl] [rofl]](/xen/styles/default/xenforo/smilies.vb/013.gif)