pastera

NES Member

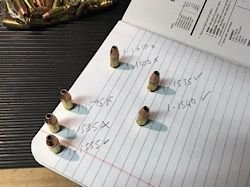

Had some from your mold that were cast at the workshop - they were running large (.360) so I ordered this mold and a .357 sizer die.Nice!

I have that mould and it drops beautiful bullet really fast.

The drop big enough for my 38 too.

Work great in 9.

And now the sizer die will sit on the shelf because this mold is dropping right at spec (range scrap with 1% additional tin)