The barrel not blowing up is key.Make sure they don’t tumble. Make sure there is no leasing.

make sure you don’t @Broccoli Iglesiasyour gun

-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

-

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

One guys exploration into casting bullets...

- Thread starter NewBeige

- Start date

what distance would be optimal for noticing a bullet that tumbles?

I'm torn between which range to visit today, indoor or outdoor....

in the meantime, I also need to start asking about Mold care. Here’s how my “New” mold looks after running 40-50lb of lead through it:

Ive torched it and wiped it off a a dry cloth a few times. The sprue plate set screw isn’t doing its job so well and I need to tighten the screw plate screw a few times during a long session. It is what it is, and now of course this mold is outta stock if I wanted to buy a backup. And the MP handles are constantly sliding off. I put little wooden shims in the holes to make them fit tighter but again I need to tape the handles in every ten or so fills.

I'm torn between which range to visit today, indoor or outdoor....

in the meantime, I also need to start asking about Mold care. Here’s how my “New” mold looks after running 40-50lb of lead through it:

Ive torched it and wiped it off a a dry cloth a few times. The sprue plate set screw isn’t doing its job so well and I need to tighten the screw plate screw a few times during a long session. It is what it is, and now of course this mold is outta stock if I wanted to buy a backup. And the MP handles are constantly sliding off. I put little wooden shims in the holes to make them fit tighter but again I need to tape the handles in every ten or so fills.

38ExtraSpecial

NES Member

You should be able to notice tumbling at 10 yards.

You’re running the mould too hot. Cutting the sprue too early is what gives that lead smear on the top of the mould and under the sprue plate. Wait a couple more second before cutting the sprue. Remember you want a cut sprue not a torn out looking sprue.

Otherwise yeah they get pretty ugly pretty quick.

You can drill through the wood handles and through the steel and pin them into place.

You can remove the set screw then add a piece of #8 or so shot in the hole and put the set screw back in. When you tighten the screw it won’t back off easily and the lead helps protect the thread of the sprue plate screw.

You’re running the mould too hot. Cutting the sprue too early is what gives that lead smear on the top of the mould and under the sprue plate. Wait a couple more second before cutting the sprue. Remember you want a cut sprue not a torn out looking sprue.

Otherwise yeah they get pretty ugly pretty quick.

You can drill through the wood handles and through the steel and pin them into place.

You can remove the set screw then add a piece of #8 or so shot in the hole and put the set screw back in. When you tighten the screw it won’t back off easily and the lead helps protect the thread of the sprue plate screw.

Artie

NES Member

Easy fix that I did on one set of mine. Won't do it to all until they start slipping. Good Luck...and the MP handles are constantly sliding off. I put little wooden shims in the holes to make them fit tighter but again I need to tape the handles in every ten or so fills.

View: https://youtu.be/Kay15NiOJHQ

Thank you to everyone that helped me get this far and for Michael for organizing the seminar that made this all possible!

View: https://youtu.be/VUMhifTZPkU

View: https://youtu.be/VUMhifTZPkU

38ExtraSpecial

NES Member

Thank you to everyone that helped me get this far and for Michael for organizing the seminar that made this all possible!

View: https://youtu.be/VUMhifTZPkU

Nice! How did the bore look after firing? Clean?

Thank you to everyone that helped me get this far and for Michael for organizing the seminar that made this all possible!

View: https://youtu.be/VUMhifTZPkU

![Party [party] [party]](/xen/styles/default/xenforo/smilies.vb/021.gif)

![Cheers [cheers] [cheers]](/xen/styles/default/xenforo/smilies.vb/018.gif)

38ExtraSpecial

NES Member

Looks fine to me but who knows the jacketed stuff can “clean up” some leading if it’s not badView attachment 411641

this is after 20+ rounds of the homemade and then about 50rds of factory. Maybe the factory stuff cleaned the barrel up, but it looks clean to me at home now.... what do you think?

Looks fine to me but who knows the jacketed stuff can “clean up” some leading if it’s not bad

A few postcards from the reloading room...

Success:

here we have primers purchased for 3.2 cents and the same primers from the same store purchased 10 months later for 16.9 cents each w a daily limit of 200 (2 sleeves). Let’s hope this is the last time that happens in our lives

and your moment of slo-mo satisfaction:

View: https://youtu.be/Q09_i9KzCZQ

And the results of a different batch of bullets where I had definite flaking upon smashing:

in the meantime, I also need to start asking about Mold care. Here’s how my “New” mold looks after running 40-50lb of lead through it:

View attachment 411426

Is that a gouge across the top towards where the handles mount?

A few postcards from the reloading room...

Success:

View attachment 411749

here we have primers purchased for 3.2 cents and the same primers from the same store purchased 10 months later for 16.9 cents each w a daily limit of 200 (2 sleeves). Let’s hope this is the last time that happens in our lives

View attachment 411751

and your moment of slo-mo satisfaction:

View: https://youtu.be/Q09_i9KzCZQ

And the results of a different batch of bullets where I had definite flaking upon smashing:

View attachment 411753

Coming together nicely.

Depending on when you started reloading you have no excuse not having a reserve supply. I can remember several slots of time since the mid eighties when it was not always easy to get ammo or reloading supplies.

Buy it cheap and stock it as deep as you can.

a simple way to keep in supply.

X amount a year you need to replace what you used x3 to keep up and build reserve. Or buy double of what you use and replace x1 when your 1/2 way through what you use.

looks like this

5k primers a year, buy 10k when you are 2500 in to your 1st 5000 order another 5k before long you will have a good reserve built up. Same for powder and bullets. Dont count on monthly stocking up.

Also if you like to shoot buy a 22 or two and enough 22lr to last through out the dry spells.

@mac1911 I was doing this but not to the calculated extent you are describing. I wasn’t thinking of extended shortages of ammo pre-apocalypse... I was preping for SHTF and the three years I might be able to survive holed up somewhere that appreciate a guy who showed up w his own ammo lolComing together nicely.

Depending on when you started reloading you have no excuse not having a reserve supply. I can remember several slots of time since the mid eighties when it was not always easy to get ammo or reloading supplies.

Buy it cheap and stock it as deep as you can.

a simple way to keep in supply.

X amount a year you need to replace what you used x3 to keep up and build reserve. Or buy double of what you use and replace x1 when your 1/2 way through what you use.

looks like this

5k primers a year, buy 10k when you are 2500 in to your 1st 5000 order another 5k before long you will have a good reserve built up. Same for powder and bullets. Dont count on monthly stocking up.

Also if you like to shoot buy a 22 or two and enough 22lr to last through out the dry spells.

Either way, I’m 100% with you on your point @mac1911. I could have done a lot better w primers especially in March when everyone was panic buying guns, the primers were all still stocked and the price was still $36.99/1k.

Like a lot of folks, I didn’t foresee the pandemic lasting over the summer, and in March, I wasn’t thinking of it being an election year and even if I did, Trump was riding the good economic market right back into office, duh... Everyone knew that then. Lol

And as far as the 22lr, we have a Ruger SR22 that eats most decent manufacturers ammo. I added a captive SS slide spring to it and it eventually started not cycling right, (Some of you saw this at the monthly steel shoot that some people in thread here attend monthly organized by @Knob Creek ) we did a bunch of rapid fire from it yesterday w the stock spring back in and it was running good on Aquila supers and CCI.

I was thinking of buying a spare barrel for my range/competition gun just to have in case I really lead up the one I already have with my first season of reloads running through it.

@TrashcanDan I don’t see what would certainly be a gouge... I think I have lead steaks built up From opening the plate to soon a few times OR from opening it too late when it’s hard to open. I will clean it up a bit today w a torch and a rag.

So next steps are to keep what I have in process flowing and then I need to really spend some time focused on securing more primers. If any of you guys find them, I’d be willing to buy 5k-10k for $40-50 per box and I will come pick them up anywhere in SE Mass.

WHOLE THREAD SUMMARIZED SO FAR:

I have a range scrap source and pick up WW when I’m at shops that have them. I smelt w a turkey fryer burner and a large crucible made from an old propane tank. I have the little Lee mold w the handle and two Redneck Gold aluminum molds (awesome product). Then I’m using a Lee bottom pour pot into MP molds 8 cavity 9mm .359. Then I’m coating w Hi-Tek Coatings (their gold color so far). I used MEK instead of acetone simply because I had it close by). Then I bake in a larger than most toaster oven for 11 mins at around 400F and water quenching them on the third or fourth coat depending on how good coverage I got out of each coat. I then spray w a dash of Aqualube 5000 from the manufactured of Hi Tek. Then I’m using a Lee sizing die to size the finished bullets. Then the Dillon 650 takes over and like magic a pile of completed cartilages appears.

My girlfriend gets credit for casting when my hands get tired, tending to the pile of sprues and refilling pot so I don’t have to stop casting. Then when we are running the machine, one person acts as case feeder (I know I need to come up w a case feeder) and the primer tube tender, in addition to disassembling duds and returning the powder etc. Now it’s “our ammo”

Last edited:

pastera

NES Member

On softer alloys you might need to use a 38 spl expander (or a custom 9mm) to keep the case from squeezing the bullet down.Previously Mike said:

I would load a dummy cartridge and make sure that you don’t run into any issue with the bullet being undersized due to too much neck tensions.

Did you dump them into cold water after the last bake?

I dumped in water some of them. I guess your going to say to bing them Back upto temp and dump them?

Ok so here is the first bullets loaded and then pulled and measured. I made adjustment and got to bullet 3. I’m not sure what direction I should be going in or if I’m close enough to stop.

Bullet1

.357 sized and coated

.383 OD of case flared

.356 bullet Post- separation

Bullet2

.356 sized and coated

.378 OD of case flared

.351 bullet Post- separation

Bullet3

.357 sized and coated

.392 OD of case flared

.374 OD of assembled cart

.356 bullet Post- separation

View attachment 411342

the overall length assembled (COL) is 1.111

View attachment 411344

Also - way too much crimp on those. You only want to remove the bell mouth on rounds that headspace on the case mouth.

What dies are you using? If Lee, I can make you a powder through expander the right size for your exact bullet. I usually use 0.010 over bullet diameter for ~0.050" then bullet size for a total length of the seating depth. A standard belling expander creates a cone that doesn't keep the bullet aligned but is adjustable.

I have a lot of leave coming up till the end of the year so I should have some shop time.

On softer alloys you might need to use a 38 spl expander (or a custom 9mm) to keep the case from squeezing the bullet down.

Also - way too much crimp on those. You only want to remove the bell mouth on rounds that headspace on the case mouth.

What dies are you using? If Lee, I can make you a powder through expander the right size for your exact bullet. I usually use 0.010 over bullet diameter for ~0.050" then bullet size for a total length of the seating depth. A standard belling expander creates a cone that doesn't keep the bullet aligned but is adjustable.

I have a lot of leave coming up till the end of the year so I should have some shop time.

thats a very nice offer. I’d be down to make some stuff with you especially a PID or two for my Lee pot and the toaster oven for coating. Or a big smelt with a specific alloy you are trying to achieve. Temperature control and alloy building is definitely areas I could use help with.

I am using all Dillon dies that came w the machine. The fill/flaring stage was lowered (increasing flare) a bit because I was having an issue w setting the bullets in the cases just before they go up into the seating die. I know what you mean though, my cases aren’t straight as an arrow from head to toe like factory ammo. I figured it was from me not having each stage in the machine tuned in very well. Any suggestions on how to “tune it”? It’s a Dillon 650xl

38ExtraSpecial

NES Member

You’re going to get that wasp waste look with a lot of dies. Especially Dillon. 9 mm is a tapered case for starters but dies from companies like Dillon that are more concerned with competition shooters and ultimate reliability are going to size the case a little smaller.thats a very nice offer. I’d be down to make some stuff with you especially a PID or two for my Lee pot and the toaster oven for coating. Or a big smelt with a specific alloy you are trying to achieve. Temperature control and alloy building is definitely areas I could use help with.

I am using all Dillon dies that came w the machine. The fill/flaring stage was lowered (increasing flare) a bit because I was having an issue w setting the bullets in the cases just before they go up into the seating die. I know what you mean though, my cases aren’t straight as an arrow from head to toe like factory ammo. I figured it was from me not having each stage in the machine tuned in very well. Any suggestions on how to “tune it”? It’s a Dillon 650xl

View attachment 411808

The best fix is a properly designed expander.

That and like @pastera said back that crimp off a bit.

The best way is to measure finished cartridge diameter. Bullet size plus brass mouth thickness X2

So if the brass is .011” and you’re using .357” you should be .379” finished diameter.

@TrashcanDan I don’t see what would certainly be a gouge... I think I have lead steaks built up From opening the plate to soon a few times OR from opening it too late when it’s hard to open. I will clean it up a bit today w a torch and a rag.

Looks like it right there.

Could also be me or maybe a lead smear?

Attachments

pastera

NES Member

And you need to use a micrometer not calipers to get that level of accuracy - it doesn't take much difference in finger pressure to change a caliper reading by 0.002"You’re going to get that wasp waste look with a lot of dies. Especially Dillon. 9 mm is a tapered case for starters but dies from companies like Dillon that are more concerned with competition shooters and ultimate reliability are going to size the case a little smaller.

The best fix is a properly designed expander.

That and like @pastera said back that crimp off a bit.

The best way is to measure finished cartridge diameter. Bullet size plus brass mouth thickness X2

So if the brass is .011” and you’re using .357” you should be .379” finished diameter.

pastera

NES Member

Pull the expander and measure it - it will probably be 0.355"or smaller.thats a very nice offer. I’d be down to make some stuff with you especially a PID or two for my Lee pot and the toaster oven for coating. Or a big smelt with a specific alloy you are trying to achieve. Temperature control and alloy building is definitely areas I could use help with.

I am using all Dillon dies that came w the machine. The fill/flaring stage was lowered (increasing flare) a bit because I was having an issue w setting the bullets in the cases just before they go up into the seating die. I know what you mean though, my cases aren’t straight as an arrow from head to toe like factory ammo. I figured it was from me not having each stage in the machine tuned in very well. Any suggestions on how to “tune it”? It’s a Dillon 650xl

View attachment 411808

If your cases are swaging your bullet then you need to increase the diameter of the expander the same amount as the bullet reduction.

The other issue is that the expander usually doesn't extrend into the case to the same depth as you seat the bullet - expanding to seating depth helps prevent setback and swaging of the bullet base.

45BPCR

NES Member

Permit me to comment on barrel leading when shooting cast bullets.

The first cartridge I handloaded for was the 357.

I used store bought cast bullets as I was (and still am, frugal)

Hot loads with 2400 would lead the barrel of my Blackhawk very badly.

I was talking with an older gentleman at the range about it and he offered this advice.

If you're going to shoot lead don't shoot jacketed.

Scrub the barrel and remove all the leading.

Soak some cotton balls with Sweet's, pack the barrel and let sit overnight.

The cotton will most likely come out blue.

Keep repeating until there no more blue balls. (Sage advice)

I did that and the leading stopped.

Running jacketed bullets down a leaded barrel irons the lead in, it doesn't remove it.

You end up with layers of lead, copper, lead, copper ect. and it's a bitch to remove.

I rarely cast with hard alloys.

I use 20-1, 16-1 and sometimes 14-1.

Those are fairly soft lead/tin alloys.

Bullet fit and obturation will prevent leading.

I use a Lyman 358429 4 cavity for most of my 38/357 needs

I cast with 16 or 14-1 and lube them with the nasty old Lyman Super Moly lube.

I use a 359 sizer die in the lubrisizer so the bullets are pretty much "as cast".

12+ grains of 2400 shoots very well with no leading.

Here's a good article, hope this helps.

Cast bullet alloy's and bullet obturation

C

The first cartridge I handloaded for was the 357.

I used store bought cast bullets as I was (and still am, frugal)

Hot loads with 2400 would lead the barrel of my Blackhawk very badly.

I was talking with an older gentleman at the range about it and he offered this advice.

If you're going to shoot lead don't shoot jacketed.

Scrub the barrel and remove all the leading.

Soak some cotton balls with Sweet's, pack the barrel and let sit overnight.

The cotton will most likely come out blue.

Keep repeating until there no more blue balls. (Sage advice)

I did that and the leading stopped.

Running jacketed bullets down a leaded barrel irons the lead in, it doesn't remove it.

You end up with layers of lead, copper, lead, copper ect. and it's a bitch to remove.

I rarely cast with hard alloys.

I use 20-1, 16-1 and sometimes 14-1.

Those are fairly soft lead/tin alloys.

Bullet fit and obturation will prevent leading.

I use a Lyman 358429 4 cavity for most of my 38/357 needs

I cast with 16 or 14-1 and lube them with the nasty old Lyman Super Moly lube.

I use a 359 sizer die in the lubrisizer so the bullets are pretty much "as cast".

12+ grains of 2400 shoots very well with no leading.

Here's a good article, hope this helps.

Cast bullet alloy's and bullet obturation

C

pastera

NES Member

Hooked it up to the toaster oven that I use for HiTek - set to 170°C the two ingots stabilized at 186°C (it's not convection)Will keep either running at the temp you want.

Was actually going to post a few pictures.

Got the time to put a controller together after spread 10 yards of loam today.

View attachment 411287View attachment 411288

Temp did not exceed 170° at all with the tune I used - it's sluggish reaching the last few degrees but the temp is stable enough that you could manage coating color pretty well.

Pretty sure I could tune it better to get rid of sluggishness but didn't spend the time on this unit that already has a home

Permit me to comment on barrel leading when shooting cast bullets.

The first cartridge I handloaded for was the 357.

I used store bought cast bullets as I was (and still am, frugal)

Hot loads with 2400 would lead the barrel of my Blackhawk very badly.

I was talking with an older gentleman at the range about it and he offered this advice.

If you're going to shoot lead don't shoot jacketed.

Scrub the barrel and remove all the leading.

Soak some cotton balls with Sweet's, pack the barrel and let sit overnight.

The cotton will most likely come out blue.

Keep repeating until there no more blue balls. (Sage advice)

I did that and the leading stopped.

Running jacketed bullets down a leaded barrel irons the lead in, it doesn't remove it.

You end up with layers of lead, copper, lead, copper ect. and it's a bitch to remove.

I rarely cast with hard alloys.

I use 20-1, 16-1 and sometimes 14-1.

Those are fairly soft lead/tin alloys.

Bullet fit and obturation will prevent leading.

I use a Lyman 358429 4 cavity for most of my 38/357 needs

I cast with 16 or 14-1 and lube them with the nasty old Lyman Super Moly lube.

I use a 359 sizer die in the lubrisizer so the bullets are pretty much "as cast".

12+ grains of 2400 shoots very well with no leading.

Here's a good article, hope this helps.

Cast bullet alloy's and bullet obturation

C

Thats awesome. I need one. let’s do thisHooked it up to the toaster oven that I use for HiTek - set to 170°C the two ingots stabilized at 186°C (it's not convection)

Temp did not exceed 170° at all with the tune I used - it's sluggish reaching the last few degrees but the temp is stable enough that you could manage coating color pretty well.

Pretty sure I could tune it better to get rid of sluggishness but didn't spend the time on this unit that already has a home

Jay77

NES Member

Quick question on sourcing lead. I know that using the internals of a battery is bad but how about using the terminals? Any risk in using those? I finally got out and tested my last batch of 8mm that I hi-tek and tossed in Lee Alox and it looks like I’m lead free.

38ExtraSpecial

NES Member

I believe the terminals are fine for melting but I would check castboolits to make sure. I can’t remember if there were issues to worry about with possible battery leaks.Quick question on sourcing lead. I know that using the internals of a battery is bad but how about using the terminals? Any risk in using those? I finally got out and tested my last batch of 8mm that I hi-tek and tossed in Lee Alox and it looks like I’m lead free.

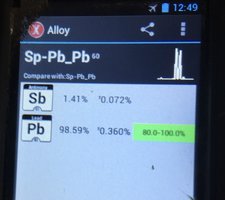

IDK, @Michael J. Spangler would know. I’d say there are so many other sources out there for pretty cheap, even touching and moving around old batteries isn’t worth the hassle to me and I melt range scrap (which is like melting dirt, akin to bringing the 3rd world into your own backyard for an afternoon). Go to a scrap yard and ask them to buy some scrapped lead. They probably have a ton or two laying around and will even sample it w a X-ray gun for youQuick question on sourcing lead. I know that using the internals of a battery is bad but how about using the terminals? Any risk in using those? I finally got out and tested my last batch of 8mm that I hi-tek and tossed in Lee Alox and it looks like I’m lead free.

Quick question on sourcing lead. I know that using the internals of a battery is bad but how about using the terminals? Any risk in using those? I finally got out and tested my last batch of 8mm that I hi-tek and tossed in Lee Alox and it looks like I’m lead free.

So I tried that over the summer.

Had 4 giant deep cycles out of ride-on floor cleaning machines, must've clocked in at or over 100lbs each, probably closer to 60 once the water was out.

So after several large boxes of baking soda to neutralize the acid I cut one open.

Huge disappointment.

The exposed terminals that you see on the outside and a bus-bar (not sure of the exact term, it runs along the inside top and connects the plates) are almost pure lead.

The actual plates in the cells- Not really worth the effort. Its thinner than paper, flakes off once its dried, and theres a paper like material in between as an insulator.

Go to a scrap yard and ask them to buy some scrapped lead. They probably have a ton or two laying around and will even sample it w a X-ray gun for you

Bins upon bins.

I turned in some junk brass over the summer and there was roof flashing and wheel weights.

I asked the guy at the door about it , he said "Send em on down" They wanted less than a buck a pound for wheel weights. You sort through it yourself, but it was steel drum sized bins.

Jay77

NES Member

Okay I’ll check over there. I was at the range the other day and I was shooting with a guy I’ve run into several times and I had my cast 8mm. We got to talking and come to find out he works at local auto salvage yard and has access to various scrap lead sources. Figure he may be a potential source for WW and possibly terminals if they are useable.

Recycling lead batteries at home is messy and to me not worth the effort. Your better off just bringing them to local scrap yard. Last I checked .27 cents pound so average battery is about $10 or so.Quick question on sourcing lead. I know that using the internals of a battery is bad but how about using the terminals? Any risk in using those? I finally got out and tested my last batch of 8mm that I hi-tek and tossed in Lee Alox and it looks like I’m lead free.

Some places just give a flat fee of $12-18 per battery. I just cash in any old batteries I get for coffee money.

Jay77

NES Member

Cool. I’ll stick with the WW for now to see how this source works out. If not I’ll pick up another couple hundred pounds of clean lead that I paid a 1.50 a pound shipped for. With it getting dark so early I’ve found some spare time.

Share: