If you need to make a alloy you can run something like this. It will give you 2% Tin

Another variable we dont know is your roof flashing. It could be pure or have a good amount of Atimony in it.

I had a batch of roof flashing tested and it came back with +3% antimony I have it right on 12 BHN with the pencil test.

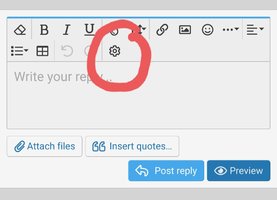

View attachment 408765

Going back over old post to understand them better with my newer found knowledge...

can I use the Muriatic acid to see if it’s pure lead vs lead w antimony? Cause the Muriatic acid had the least reaction on the roofing lead out of all the other alloy runs I had around to test....

A recap:

I had six bars I know are contaminated w zinc

I had about 30 bars I made out of range scrap while adding wheel weights along the way (maybe 20% WW).

I also have about 30 bars that are straigh range scrap.

And then there are about 20 that are just wheel weights. I’m upto about ballpark 200lbs.

My goal is to position myself so I’m not outside smelting in the depths of winter. Winter will be for casting and making friends at tire shops.