38ExtraSpecial

NES Member

Ouch!I read some where sulfur was used to remove copper? Nice you found a yard that will Xray stuff, local place I go wants $35 a trigger pull.

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

Ouch!I read some where sulfur was used to remove copper? Nice you found a yard that will Xray stuff, local place I go wants $35 a trigger pull.

Thankfully a generous NES'r tagged my bulk stash for me.Ouch!

Glad you have a decent place to go. 2 places near me are not really known for their reselling.$35 bucks? Wow. $35 is more than a BJ costs around these parts. I brought my GF, she dealt with the trigger man and the photos of the results while I sorted a bucket of shells for the 38/357's and I tipped the guy $5 bucks and I also was buying those shell casings and about $140 in lead as well. My mistake was A) doing this on a Friday B) showing up after 10am. If I was there at 830 am on a Tuesday I could have been the old customer at non-ferrus area for an hour. My part of state is also now in the "red zone" so Its now "no wandering, stay by the loading dock", in the same place that I was all over shopping around for scrap last week. Covid even takes the fun out of going to the scrap yard! WTF lol

Are we talking lead or BJs?Glad you have a decent place to go. 2 places near me are not really known for their reselling.

This is NESLead , Im not sure i would want a re sold BJ?

what are lead stamps?Big day tmwr. Shooting my own bullets w an audience for first time

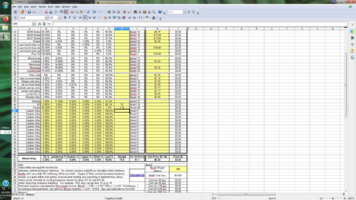

I tackled the spreadsheet and got an alloy that uses three sets of material I have on hand: melted lead stamps, Wheel weights (W3), and Pewter bars I had made up. Anyone wanna check my math before I bust out the turkey fryer?

View attachment 413947

It was small blocks from a printing press. Blocks engraved with calligraphy for stamping or using in a printing press. There were two coffee cans full of them and I got them XRF testes and imputes the results in the sheet.what are lead stamps?

Ok , "type" or linotype, mono type ectectIt was small blocks from a printing press. Blocks engraved with calligraphy for stamping or using in a printing press. There were two coffee cans full of them and I got them XRF testes and imputes the results in the sheet.

I prefer that 2% tin 3% antimony only for the reason that you need hardness to fight the neck tension.Big day tmwr. Shooting my own bullets w an audience for first time

I tackled the spreadsheet and got an alloy that uses three sets of material I have on hand: melted lead stamps, Wheel weights (W3), and Pewter bars I had made up. Anyone wanna check my math before I bust out the turkey fryer?

View attachment 413947

do you think the BHN is going to matter much at 11.3-11.9 ? Are you quenching your bullets ? how much over size are you running your bullets. I quess I have not had this problem yet?I prefer that 2% tin 3% antimony only for the reason that you need hardness to fight the neck tension.

Mac is right about being able to run a little softer alloy with coating but then you need to get a custom expander made so you can run the oversized softer alloy without sizing it down due to neck tension.

I would mix it up the way you have it on the sheet and invest in a custom expander so you can run a softer alloy.

I should take my own advice too.

I should have added that the reason I go with the higher alloy is so that I can quench and gain the hardness.do you think the BHN is going to matter much at 11.3-11.9 ? Are you quenching your bullets ? how much over size are you running your bullets. I quess I have not had this problem yet?

I have been running Clip on wheel weights and adding 2% tin , water quench for anything over 1200 fps 75% I run cast bullets at .001+ I have only slugged a few worn barrels and one 1911 which has which comes out at .452"+ grove dia--- shoots ok but will lead and copper foul easily.

I only recently made up my "alloys" and had them tested my most common alloy now is roughly 2/3/95

I have a small batch of "hardball" and a nice batch of high tin alloy

I would just mix your 70lbs Wheel weights with 1.5 to 1.75lbs of your pewter. and water quench to up the hardness to about 15-18bhn? Water quench into a mild cleaning solution pre coating ?

The more I read about the coating the more I feel soft alloys are fine in pistol applications. Full power cast acp does well with 13-18 bhn in my guns mostly WW alloy water quenched.

View attachment 414062

OK, I’m dizzy.I prefer that 2% tin 3% antimony only for the reason that you need hardness to fight the neck tension.

Mac is right about being able to run a little softer alloy with coating but then you need to get a custom expander made so you can run the oversized softer alloy without sizing it down due to neck tension.

I would mix it up the way you have it on the sheet and invest in a custom expander so you can run a softer alloy.

I should take my own advice too.

OK, I’m dizzy.

What’s the goal here as far as alloy mix and hardness?

I work with spreadsheets for work. I was “working the sheet” to get to my 95 lead/3% Antimony/2% Tin mix based on actual tested alloys I have on hand (don’t mind what they are called in my sheet, it’s how they tested that matters, I think lol). I made a small error in my calculations though. The BN formula in the sheet I have only is calculating a result from the last two lines.

I will PM you both for your working versions of the sheet. i want to look at some formulas and compare them to each other. I find older sheets like this that are passed around can pick up edits that future users don’t notice are affecting their results. Thanks!

BTW, We shot a match today and we had about 300 shots of zero failures from the bullets that were cast and coated as a result of this thread and the seminar @Michael J. Spangler was so cool enough to organize for the members of the board that were lucky enough to attend.

thats ok Im still dizzy and I TEND TO FORGET THE MORE I LEARN!OK, I’m dizzy.

What’s the goal here as far as alloy mix and hardness?

I work with spreadsheets for work. I was “working the sheet” to get to my 95 lead/3% Antimony/2% Tin mix based on actual tested alloys I have on hand (don’t mind what they are called in my sheet, it’s how they tested that matters, I think lol). I made a small error in my calculations though. The BN formula in the sheet I have only is calculating a result from the last two lines.

I will PM you both for your working versions of the sheet. i want to look at some formulas and compare them to each other. I find older sheets like this that are passed around can pick up edits that future users don’t notice are affecting their results. Thanks!

BTW, We shot a match today and we had about 300 shots of zero failures from the bullets that were cast and coated as a result of this thread and the seminar @Michael J. Spangler was so cool enough to organize for the members of the board that were lucky enough to attend.

OK, I’m dizzy.

What’s the goal here as far as alloy mix and hardness?

I work with spreadsheets for work. I was “working the sheet” to get to my 95 lead/3% Antimony/2% Tin mix based on actual tested alloys I have on hand (don’t mind what they are called in my sheet, it’s how they tested that matters, I think lol). I made a small error in my calculations though. The BN formula in the sheet I have only is calculating a result from the last two lines.

I will PM you both for your working versions of the sheet. i want to look at some formulas and compare them to each other. I find older sheets like this that are passed around can pick up edits that future users don’t notice are affecting their results. Thanks!

BTW, We shot a match today and we had about 300 shots of zero failures from the bullets that were cast and coated as a result of this thread and the seminar @Michael J. Spangler was so cool enough to organize for the members of the board that were lucky enough to attend.

It’s just like reloading. It’s all weird and technical till you get into it then you realize it isn’t that hard unless you make it that way.I just came by to say that you guys explain it effortlessly but that it is a highly involved process. I’m impressed by how much you guys know about casting and following this thread has been an eye opening experience. I’m looking to finally pick up these wheel weights from my local mechanics and tagging along for a cast soon

got it, like i said even when I was shooting alot of cast 9mm I did not have any problems and I ran straight clip on wheel weight then. I only have my p38 left for 9mm and I run plain jain 115 fmjs in thatI should have added that the reason I go with the higher alloy is so that I can quench and gain the hardness.

9mm differentiates itself from something like 45 with its brass and dies leading to undersized bullets. The only reason to go with the harder alloy is to water drop and to use the hardness to fight deformation from the loading process.

right its to get you in the range you want to be. so far my pencil tests come in slightly harder than some of the alloy calculator out puts.UPDATE: The official alloy calculator thread is over at : Lead alloy calculators

I would at the very least look at post #1 for the latest version, and #259 and #260. I copied post #260 and pasted it into my notes at the bottom of the sheet...

Quoted from post #260 by the designer of the spreadsheet: "limitations of the hardness formula. It is really only valid with tin and antimony percentages found in boolit alloys. The formula produces good values when both Sn and Sb are higher that about 1%, but not higher than about 6%. It is all we have so far, so it is what we use. Just keep that in mind when using the calculator."

You sir are lucky. I’ve seen more 9 issues than anything but it’s really all about the expander.got it, like i said even when I was shooting alot of cast 9mm I did not have any problems and I ran straight clip on wheel weight then. I only have my p38 left for 9mm and I run plain jain 115 fmjs in that

i over think alot of it read all the stuff because I havew more time to do that than shoot and cast ectect. more times than not when I get down to it I run as simple as possible.I just came by to say that you guys explain it effortlessly but that it is a highly involved process. I’m impressed by how much you guys know about casting and following this thread has been an eye opening experience. I’m looking to finally pick up these wheel weights from my local mechanics and tagging along for a cast soon

I just use the lee powder through expanders.You sir are lucky. I’ve seen more 9 issues than anything but it’s really all about the expander.

I guess will all the stations on a 650 Dillon @NewBeige could add a Lyman M die in and use a softer alloy if he ever runs out of the hard stuff.