-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

-

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OFFICIAL: NES BULLET CASTING SEMINAR

- Thread starter asp

- Start date

asp

NES Member

.3557? hard to say the 4th digit. My guess is somewhere .3556-8 based on what it looks like on this side. That's nothing short of way small for a .357. I remember seeing something screwed into the muzzle of that gun. Also, something I think I may have forgotten to mention was to make sure the throats in the cylinders are larger than the bore dia. You don't want the throats swaging down the bullet before it gets to the bore. That's almost a guarantee to get leading.

In other news, there was a pair of welding gloves left after the seminar. We thought they belonged to BillNed but it turns out they're not mine, Mike's, or Bill's. Anyone missing a pair of gently used welding gloves?

In other news, there was a pair of welding gloves left after the seminar. We thought they belonged to BillNed but it turns out they're not mine, Mike's, or Bill's. Anyone missing a pair of gently used welding gloves?

MaverickNH

NES Member

Thanks for that. It's a 5-flute V-Anvil Mitutoyo. I rotated the slug around so one grove is up and two other grooves touch the V-Anvil, so I think it's accurate. The largest number I found was 0.3561 when rotating with each groove up.

I've read where there is sometimes a constriction of as much as 0.001 where the barrel screws into the frame, and that one can slug from both ends of the barrel part-way, and push the slug back out, to measure both ends. I'll try that, and also slug the cylinders. I have some Pin Gauges (0.001 steps sized minus 0.0002 from increments) and will try those on the cylinders too. Stay tuned for more data.

When you spend $1000+ on a S&W M&P R8 Custom Shop revolver, you have expectations...

I've read where there is sometimes a constriction of as much as 0.001 where the barrel screws into the frame, and that one can slug from both ends of the barrel part-way, and push the slug back out, to measure both ends. I'll try that, and also slug the cylinders. I have some Pin Gauges (0.001 steps sized minus 0.0002 from increments) and will try those on the cylinders too. Stay tuned for more data.

When you spend $1000+ on a S&W M&P R8 Custom Shop revolver, you have expectations...

asp

NES Member

Sounds like you're on the right path. I'm curious to hear your findings

Mac, not sure what factory specs are but between Mike and I we have checked at least 5 38 or 357 guns and all were above .3565 and we have been shooting bullets sized to .358 with pretty good success. .355 sounds more like a 9mm but every gun is different.

Mac, not sure what factory specs are but between Mike and I we have checked at least 5 38 or 357 guns and all were above .3565 and we have been shooting bullets sized to .358 with pretty good success. .355 sounds more like a 9mm but every gun is different.

Last edited:

38ExtraSpecial

NES Member

Thanks for that. It's a 5-flute V-Anvil Mitutoyo. I rotated the slug around so one grove is up and two other grooves touch the V-Anvil, so I think it's accurate. The largest number I found was 0.3561 when rotating with each groove up.

I've read where there is sometimes a constriction of as much as 0.001 where the barrel screws into the frame, and that one can slug from both ends of the barrel part-way, and push the slug back out, to measure both ends. I'll try that, and also slug the cylinders. I have some Pin Gauges (0.001 steps sized minus 0.0002 from increments) and will try those on the cylinders too. Stay tuned for more data.

When you spend $1000+ on a S&W M&P R8 Custom Shop revolver, you have expectations...

I've heard the restrictions are mostly from Rugers.

Sent from my iPhone using Tapatalk

Sounds like you're on the right path. I'm curious to hear your findings

Mac, not sure what factory specs are but between Mike and I we have checked at least 5 38 or 357 guns and all were above .3565 and we have been shooting bullets sized to .358 with pretty good success. .355 sounds more like a 9mm but every gun is different.

If I can recover my hard drive I will post what I found. For what it's worth I have driven. The lee TL356-124 TC which drop around 3555-3557" through my 19-2 with only a bit of leading right at the muzzle after 100 rounds or so. Accuracy was so so...I have since switched to the lee TL358 158SWC

No leading yet. I run lube with LLA I don't size them and I'm running whimp loads...

9mm.....I gave up. Leads up with in 30 rounds with everything I tried.

asp

NES Member

Unlikely this week for me. Mike leaves for Idaho on Thursday, so probably not for him either but you never know. If he goes and you're going, I'll use it as a good excuse to get out of the house.

MaverickNH

NES Member

Thanks for that. It's a 5-flute V-Anvil Mitutoyo. I rotated the slug around so one grove is up and two other grooves touch the V-Anvil, so I think it's accurate. The largest number I found was 0.3561 when rotating with each groove up.

I've read where there is sometimes a constriction of as much as 0.001 where the barrel screws into the frame, and that one can slug from both ends of the barrel part-way, and push the slug back out, to measure both ends. I'll try that, and also slug the cylinders. I have some Pin Gauges (0.001 steps sized minus 0.0002 from increments) and will try those on the cylinders too. Stay tuned for more data.

OK - a bit more data in on that S&W M&P R8 Revolver:

1. Removed and cleaned cylinder well, with solvent wash. Washed Pin Gauges with solvent.

2. A 0.358 (-0.0002) Pin Gauge does NOT pass cylinder throats on all 8 cylinder bores

3. A 0.357 (-0.0002) Pin Gauge DOES pass cylinder throats on all 8 cylinder bores.

Still need:

a) 1/2 size pin gauges

b) Slug both ends of the barrel

c) Slug the cylinder throats for precision micrometer reading

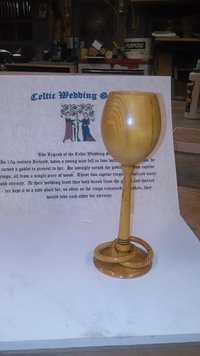

View attachment 147880

The new bullet mold tappers from Eric Gale of Freestyle Woodworking are here. I have put the clear pvc sleeve on them to protect the wood it fit like a glove. Just need to get them to Mike and Anthony now.

Those really are a piece of art. Just beautiful.

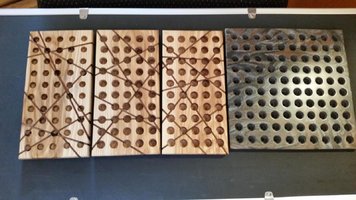

Here is my first score of wheel weights from the local tire shop. I offered $20/ 5 gal bucket and he agreed without question. I told him I'd be back in a couple weeks. Weighed in at 110 lbs.

MaverickNH

NES Member

Here is my first score of wheel weights from the local tire shop. I offered $20/ 5 gal bucket and he agreed without question. I told him I'd be back in a couple weeks. Weighed in at 110 lbs.

Great hoard! I'll be hitting some Mom & Pop tire shops in MHT this weekend. A few crisp $20 bank machine notes and the guy on duty should have no doubts. "Gee boss, I dunno, They were against the wall over there last time I looked. Dang!"

That was just for one bucket. I separated it into two for easier handling. The bucket from the shop was only 3/4 full and the guy said "I still owe you a 1/4 bucket next time" so it seems he may be a great guy to deal with. There are alot of big 4oz weights in there and no trash.

asp

NES Member

Not looking good for tonight.OK let me know

Grats on the lead scores guys. Glad to see that people have been bitten by the bug.

Bret- Glad to hear the cylinder's throats are all bigger than the bore. That's what you want.

Hey guys, my stash and supplies are growing at a good rate. I've been looking around shops for ingot molds without any luck and also been looking in stores for mini muffin tins but all I find is what looks like two parts soldered together. I remember Anthony saying that those ones will fall apart from the heat melting the solder. Aside from going to Shooters Supply later after dinner (and being a little better than an hour away) do you guys have any suggestions? Thanks

Share:

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)