groundscrapers

NES Member

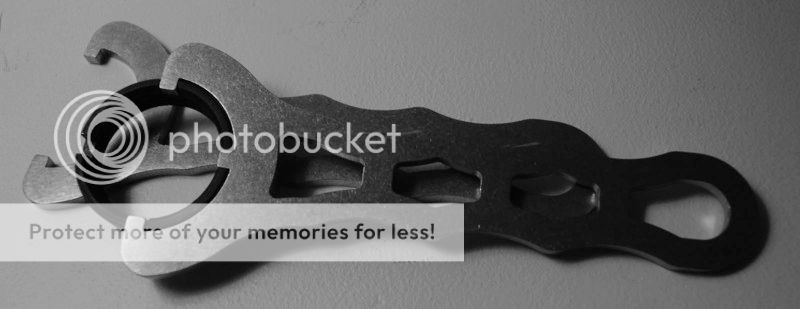

So I was feeling cheap and decided to have my friend cut me a wrench I drew up in autocad versus buying an armorers wrench (which I don't really need at the moment)

this was the outcome.

1/8" 18-8 stainless.

Only issue I have is the tabs that interface with the nut are a little too long and hit the threads as the nut is engaged. ( why they made the buffer tube so the threads get larger in diameter is beyond me lol). I can make a slight tweak with my dremel and call it a day. For those of you green members I will probably put the second one out there for karma. For you non green members its a good reason to become green.

this was the outcome.

1/8" 18-8 stainless.

Only issue I have is the tabs that interface with the nut are a little too long and hit the threads as the nut is engaged. ( why they made the buffer tube so the threads get larger in diameter is beyond me lol). I can make a slight tweak with my dremel and call it a day. For those of you green members I will probably put the second one out there for karma. For you non green members its a good reason to become green.

Last edited by a moderator:

![Wink [wink] [wink]](/xen/styles/default/xenforo/smilies.vb/002.gif)

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif)