Well I found myself a new hobby. I'm now addicted to making holsters. I spent the last few nights making myself some IWB holsters. I've worked with leather before so it was nothing new to me. Kydex on the other hand is all new. After a short learning curve with the Kydex I was getting the stuff to form the way I wanted.

My father always tought me to be a craftsman and not to half ass anything. He always tells me to put my heart and soul into everything I do. I'm now teaching my son the same thing. He's only 12 and already asking me to show him how to make a holster. If he takes to it I'll be buying him his own leather working tools.

This is pretty much my start to finish process for making a holster.

1. Hand cut the leather from a few patterns I made.

2. Bevel the edges and burnish them. Beveling and burnishing makes for a nice edge on the leather that won't wear against your skin when wearing the holster.

3. Make a vacuum form of firearm in Kydex.

4. Cut out Kydex form on bandsaw.

5. Wet sand all edges of Kydex to a nice smooth, shinny edge.

6. Drill out mounting holes in Kydex. Bevel holes for a nice smooth edge.

7. Position Kydex form on leahter and mark mounting holes. Punch out all mounting holes in the leather.

8. Seal leather with an acrylic sealer and let dry.

9. Wipe leather with a leather conditioner.

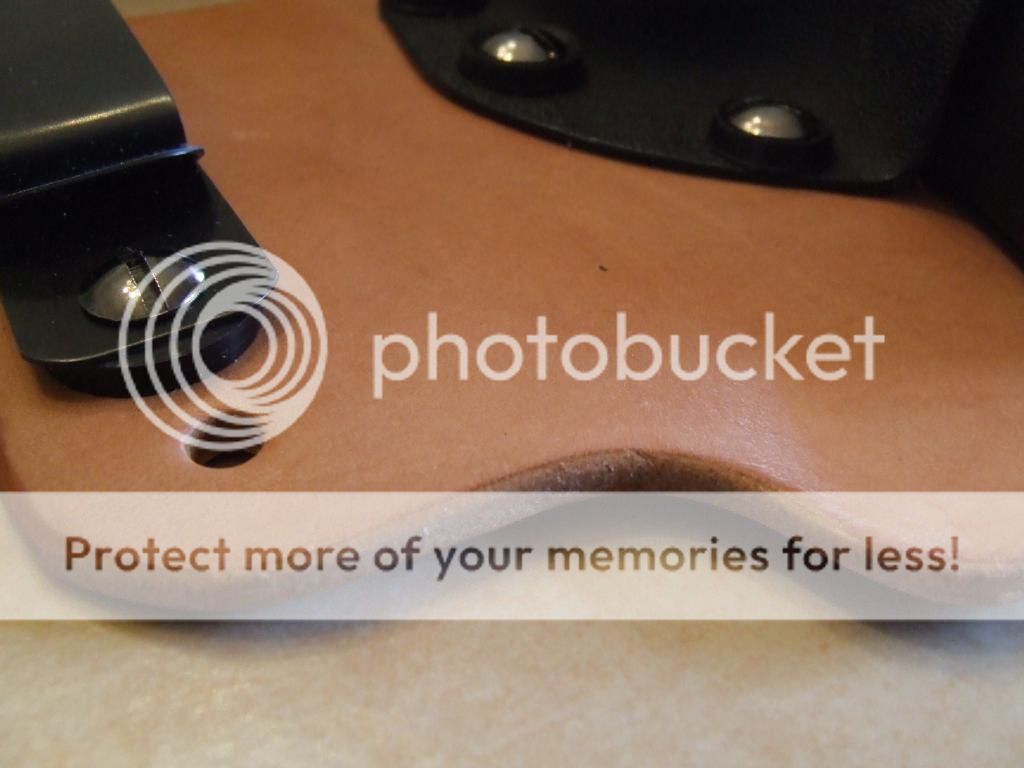

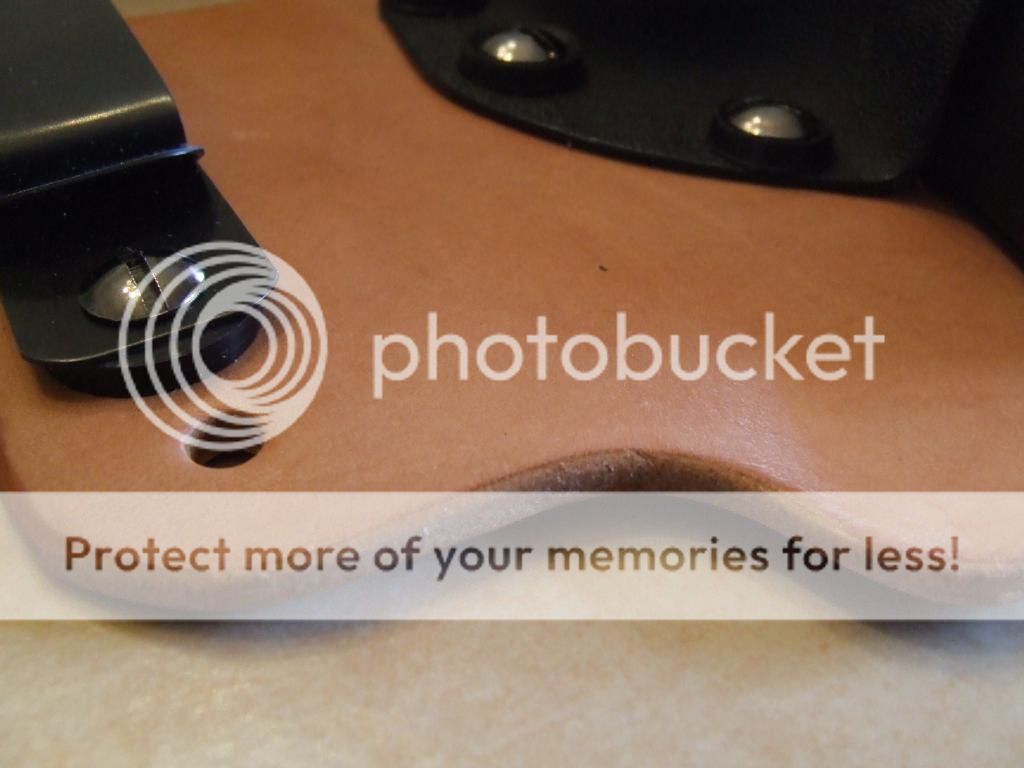

10. Install Kydex form and belt clips.

11. Test fit and adjust tension.

A couple of the holsters have rubber washers under the mounting screws. The Chicago screws I had were to long and needed washers under them. I ordered some shorter ones. Hopefully they will be in this week. I'm not really a big fan of the rubber washer look. Even though it gives a more "industrial" look.

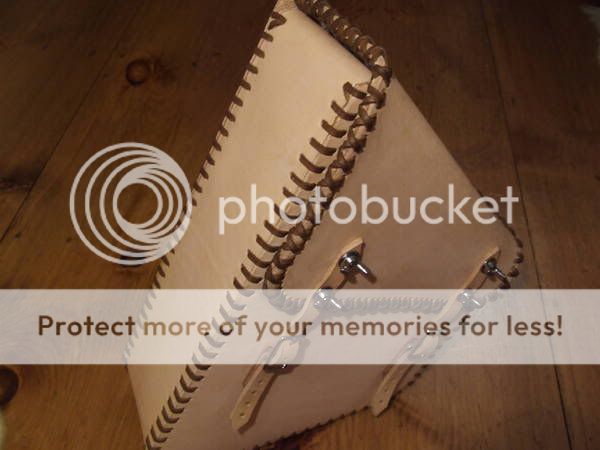

The holsters on the left are made with horsehide. The upper right is veg. tanned leather. Lower right is drum dyed black. So it is black all the way through to the back. The holster with the Ruger sp101 was made with .080 Kydex. It has less definition and is harder to mold. The other three holsters were made with .060 kydex.

My father always tought me to be a craftsman and not to half ass anything. He always tells me to put my heart and soul into everything I do. I'm now teaching my son the same thing. He's only 12 and already asking me to show him how to make a holster. If he takes to it I'll be buying him his own leather working tools.

This is pretty much my start to finish process for making a holster.

1. Hand cut the leather from a few patterns I made.

2. Bevel the edges and burnish them. Beveling and burnishing makes for a nice edge on the leather that won't wear against your skin when wearing the holster.

3. Make a vacuum form of firearm in Kydex.

4. Cut out Kydex form on bandsaw.

5. Wet sand all edges of Kydex to a nice smooth, shinny edge.

6. Drill out mounting holes in Kydex. Bevel holes for a nice smooth edge.

7. Position Kydex form on leahter and mark mounting holes. Punch out all mounting holes in the leather.

8. Seal leather with an acrylic sealer and let dry.

9. Wipe leather with a leather conditioner.

10. Install Kydex form and belt clips.

11. Test fit and adjust tension.

A couple of the holsters have rubber washers under the mounting screws. The Chicago screws I had were to long and needed washers under them. I ordered some shorter ones. Hopefully they will be in this week. I'm not really a big fan of the rubber washer look. Even though it gives a more "industrial" look.

The holsters on the left are made with horsehide. The upper right is veg. tanned leather. Lower right is drum dyed black. So it is black all the way through to the back. The holster with the Ruger sp101 was made with .080 Kydex. It has less definition and is harder to mold. The other three holsters were made with .060 kydex.

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif) . I need to try making some outside the waistband holsters next.

. I need to try making some outside the waistband holsters next.

![Wink [wink] [wink]](/xen/styles/default/xenforo/smilies.vb/002.gif)