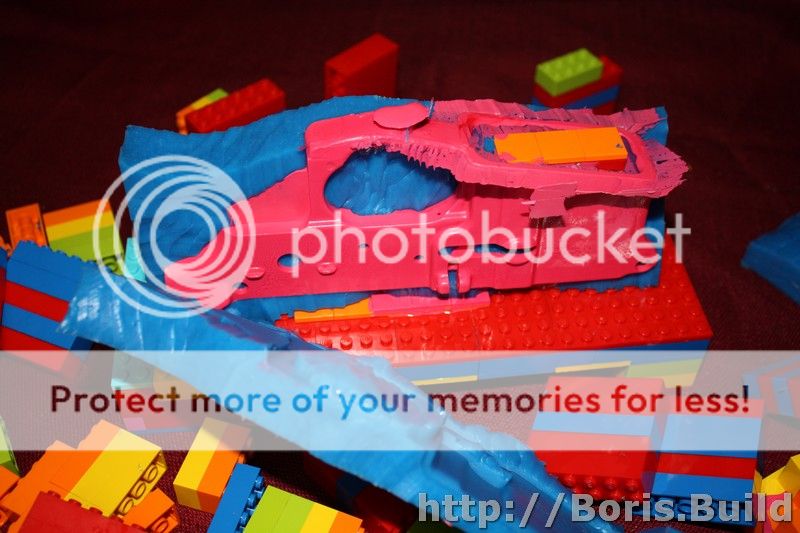

Boris, is that plastic?

it's plastic and it's fabulous, don't be hatin'

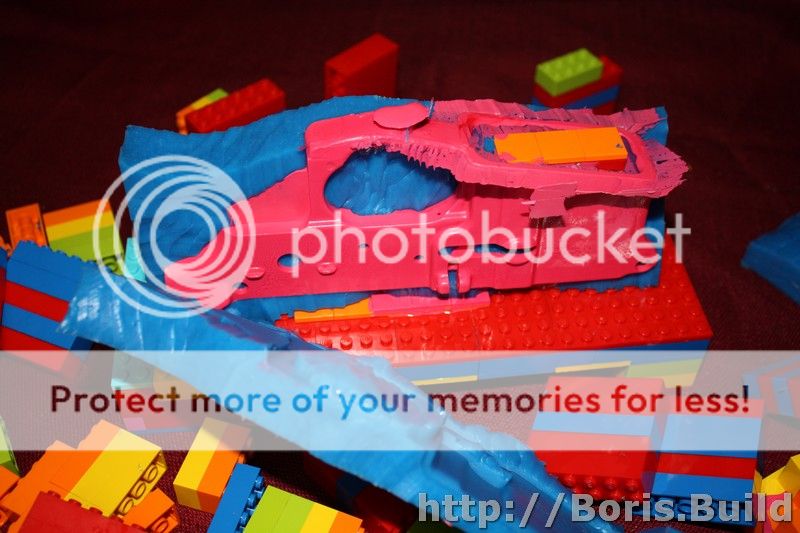

My friend has one and 500 556 rounds later it's still going strong

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

Boris, is that plastic?

I'm not knocking it. I was just curious.

What brand is it?

What do you mean? It's DIY, I made a mold to make these. http://www.ar15.com/forums/t_3_4/67..._of_ARs_cheaper__faster__gentler_.html&page=1

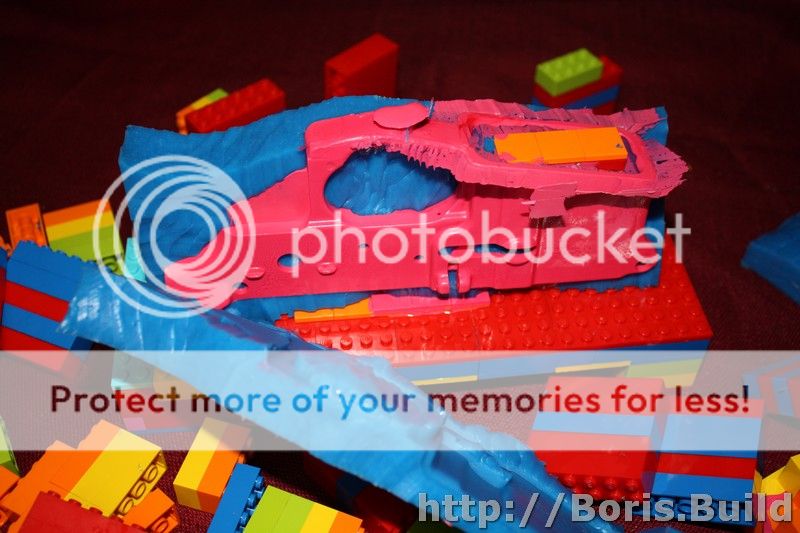

Question, did you do any of these with the steel reinforced pin holes like in your arfcom pics? If so, how did you embed that in the middle of the mold so that the holes would line up correctly?

In the mold everything is reversed, so a void (like a hole) is actually rubber, it's a rubber peg onto which you hang the reinforcement.

for the FCG I use boxed unit. After a few hundred rounds the pin holes will egg.

Drop the hand guard . Can't have one on a ar pistol in mass. It counts as a barrel shroud.

Lighten the bcg. Can go ti, but you can Swiss cheese a semi bcg.

Slick slide upper.

Boris,

Would you ever consider having a mold making party? Where we could make a mold and then maybe drink some Wodka,

Then when the mold is dry, we could cast our first fruity lower?

re longevity - I'm wondering how much stronger it would be if fiberglass chop was added to the resin before casting.

Don

Sorry, I asked that before I finished the 14 pages over at arfcom. In theory, the best place for the reinforcement is stuck in the middle of the plastic, no exposure. I've got some idea's and will definitely be trying this out. If you have an extra reinforcement laying around please let me know. I want to clay the exterior of the lower to ad thickness around the of the takedown whole, like a 308. This will add material to the weak point and also allow me to float plastic on both sides of the reinforcement so no metal is visible. I'm ordering my supplies today.

I like your fancy buffer tube reinforcement . How do you form that?

(iii) a shroud that is attached to, or partially or completely encircles, the barrel and that permits the shooter to hold the firearm with the nontrigger hand without being burned;

Integrated upper make a difference?

the glove lobby was behind this one.That's one hell of a reason to ban something. Their reasoning doesn't even pretend to be legitimate.

Pin and weld?Yeah, except you just added 8 oz compared to a carbon fiber tube with an Al barrel nut.

Pin and weld?

Sent from my SM-T237P using Tapatalk

Too bad you'd have to remove the hand guard to get around the the awb too.

pistols can violate the ma awb . It's for stuff like ar ak pistols , tech9 , mac's , Uzi etc.

It's easier to just sbr a ar in mass then build one to match the awb .

Seems like building one wouldn't be too hard. These are pretty light and are full blown rifles, not pistols:http://www.calguns.net/calgunforum/showthread.php?t=1005966

Seems a lot easier than dealing with SBR BS. Specially if you might move in the future.I need to look into that more.

Seems a lot easier than dealing with SBR BS. Specially if you might move in the future.

Moving not that bad. My view a ar pistol is pointless cause of the buffer tube.

I'd rather have a sbr then a pistol ar.

That said I wouldn't mind a pistol Ak.

But that barrel is so thin that I would worry about heat dissipation and barrel life.

If you do a party etc I'll need to come .

I need a lower I can cut the buffer tower off and use clay to shape a bullpup idea I have to make a mold . Just been too cheap and lazy to buy a 80%.

Google around.

You might be able to find torch cut/demilled M16 receivers...

What do you mean? It's DIY, I made a mold to make these.

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif)