- Joined

- Dec 2, 2005

- Messages

- 9,014

- Likes

- 5,488

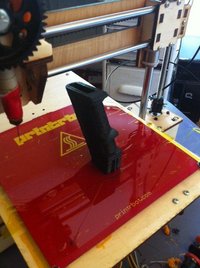

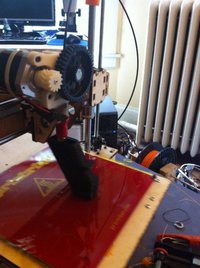

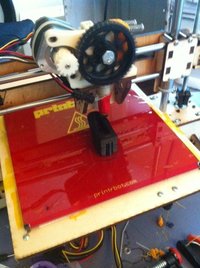

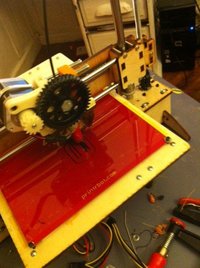

There was a project on Kickstarter for a low cost 3D printer, we finally received our kit last month, and it's working pretty well now.

Usable build area is about 180mm x 180mm x 180mm. Resolution is about 0.2mm, with a 0.5mm nozzle, and up to .1mm vertical layers (although that's pretty slow to print).

Here's our printer, with some test prints in ABS plastic. It's really tough stuff!

https://plus.google.com/u/0/photos/...s/5763588316280579537?authkey=COSS7oymkLTPmwE

I'm going to try printing out an AR15 lower to try with our M&P 15-22, when I get a chance:

http://www.thingiverse.com/thing:26677

Usable build area is about 180mm x 180mm x 180mm. Resolution is about 0.2mm, with a 0.5mm nozzle, and up to .1mm vertical layers (although that's pretty slow to print).

Here's our printer, with some test prints in ABS plastic. It's really tough stuff!

https://plus.google.com/u/0/photos/...s/5763588316280579537?authkey=COSS7oymkLTPmwE

I'm going to try printing out an AR15 lower to try with our M&P 15-22, when I get a chance:

http://www.thingiverse.com/thing:26677

![Wink [wink] [wink]](/xen/styles/default/xenforo/smilies.vb/002.gif)

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif)