-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hard Cast- Local Lead Source or Just Order from Roto Etc.?

- Thread starter Mountain

- Start date

Ya it’s lead. Bought it from Ace Hardware. It’s got that texture on one side. The other side is perfectly smooth.Is that lead? Looks like zinc

Is that texture the metal or adhesive

. I have someone who secretly drops off random lead stuff seen this on my way to the bank today. Next to where I park. View attachment 362854

View attachment 362855

About 4lbs of Nice&Soft

Lank

NES Member

If I cannot get my hands on wheel weights, is there other materials commercialyStraight wheel weights will work for all of the abo

Straight wheel weights will work for all of the above.

Maybe add some straight lead to soften it up for low velocity .45

thanks again. so if i cannot get my hands on wheel weights, purchasing an ingot of lyman #2 to get BHN above 5 (for pure lead) would also work? 50/50 mix in melting pot?

Lank

NES Member

Ah! thanks what i have (~60 lbs)Is that lead? Looks like zinc

Is that texture the metal or adhesive

. I have someone who secretly drops off random lead stuff seen this on my way to the bank today. Next to where I park. View attachment 362854

View attachment 362855

About 4lbs of Nice&Soft

@Lank

Quick search yields this-

"I just did some today. I mixed equal portions of pure lead and monotype. Cast 200 RCBS 35-200 FN, they weigh 202 gr. as cast, hardness tested 18 BHN.

For WW equivilent, 3-to-1 lead to lino should be about right."

So maybe 4 to 1 of lead (5 bhn) to lyman#2 (bhn 15)?

Did a search for a BHN calculator, they're out there, I have no interest in downloading it

Some good mixing info on this website-

www.castbulletassoc.org

www.castbulletassoc.org

Probably an answer here-

Maybe the casting gurus @Michael J. Spangler or @mac1911 can guide you, way more knowledgeable than I am.

Quick search yields this-

"I just did some today. I mixed equal portions of pure lead and monotype. Cast 200 RCBS 35-200 FN, they weigh 202 gr. as cast, hardness tested 18 BHN.

For WW equivilent, 3-to-1 lead to lino should be about right."

So maybe 4 to 1 of lead (5 bhn) to lyman#2 (bhn 15)?

Did a search for a BHN calculator, they're out there, I have no interest in downloading it

Some good mixing info on this website-

Mixing linotype with straight lead

Can any of you guys give me a basic ratio for mixing linotype with straight lead to make something similar

Probably an answer here-

Lead and Lead Alloys

Galena , the silver stream itself, the base metal of the craft. Pb, Linotype, monotype, Wheel Weights and the rest!

castboolits.gunloads.com

Maybe the casting gurus @Michael J. Spangler or @mac1911 can guide you, way more knowledgeable than I am.

Last edited:

pastera

NES Member

If you are ordering, get some super hard and tin nuggets - then you can tune your mixIf I cannot get my hands on wheel weights, is there other materials commercialy

thanks again. so if i cannot get my hands on wheel weights, purchasing an ingot of lyman #2 to get BHN above 5 (for pure lead) would also work? 50/50 mix in melting pot?

38ExtraSpecial

NES Member

Quick search yields this-

"I just did some today. I mixed equal portions of pure lead and monotype. Cast 200 RCBS 35-200 FN, they weigh 202 gr. as cast, hardness tested 18 BHN.

For WW equivilent, 3-to-1 lead to lino should be about right."

So maybe 4 to 1 of lead (5 bhn) to lyman#2 (bhn 15)?

Did a search for a BHN calculator, they're out there, I have no interest in downloading it

Some good mixing info on this website-

Mixing linotype with straight lead

Can any of you guys give me a basic ratio for mixing linotype with straight lead to make something similarwww.castbulletassoc.org

Probably an answer here-

Lead and Lead Alloys

Galena , the silver stream itself, the base metal of the craft. Pb, Linotype, monotype, Wheel Weights and the rest!castboolits.gunloads.com

Maybe the casting gurus @Michael J. Spangler or @mac1911 can guide you, way more knowledgeable than I am.

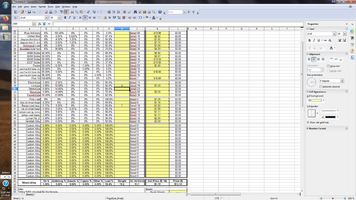

This is what you need for calculating. I believe it gives an estimated Brinell too

Attachments

what are you looking to do ? Do you have a hardness your looking to get to? Are gou looking to get as much use out of the 60lbs you have? Few thingsAh! thanks what i have (~60 lbs)

Have you smelted the lead you have now down into clean ignots?

Y- You can figure out what alloy you need to blend with 60lbs of soft lead to get the max amount of alloy then blend if.

N- ask around the muzzle loader groups see if they want to buy flashing. i have a few Muzzle Loader friends who rather have flashing in its "natural" state. Assures them its soft flashing. They will give me .50-.60 lb even the stuff covered in tar and silicone.......take it!

If your going to buy virgin alloy you need to buy the correct alloy to maximize your return.

Buying lyman #2 and then mixing pure is a waste of nice lyman #2.

Give me a bit i will figure out something.

Lank

NES Member

Thanks all and sorry for noob questions. I am trying make as much 9mm plinking ammo as possible. i havent smelted down anything yet. I thought that i could simply melt down the flashing and pour into cast.what are you looking to do ? Do you have a hardness your looking to get to? Are gou looking to get as much use out of the 60lbs you have? Few things

Have you smelted the lead you have now down into clean ignots?

Y- You can figure out what alloy you need to blend with 60lbs of soft lead to get the max amount of alloy then blend if.

N- ask around the muzzle loader groups see if they want to buy flashing. i have a few Muzzle Loader friends who rather have flashing in its "natural" state. Assures them its soft flashing. They will give me .50-.60 lb even the stuff covered in tar and silicone.......take it!

If your going to buy virgin alloy you need to buy the correct alloy to maximize your return.

Buying lyman #2 and then mixing pure is a waste of nice lyman #2.

Give me a bit i will figure out something.

you could, you dont know the alloy content of the flashing. Flashing could be pure and or have Antimony in it. If your going to use a bottom pour pot for casting its a good idea to smelt and clean up you alloy before you run it through the pot. If your going to ladle pour your mold you could do it in your pot. Thing is if your going to be making up alloys doing it by the 10lb pund pot is not very efficient. Depends on what you want out of it I guess.Thanks all and sorry for noob questions. I am trying make as much 9mm plinking ammo as possible. i havent smelted down anything yet. I thought that i could simply melt down the flashing and pour into cast.

Heres my thoughts

your looking for what 12 bhn or so

assume your flashing is 5 BHN 60 lbs you could go with 10lbs of Foundry type lead and have

tin Antimony lead lbs Bhn

2.14% tin | 3.29% antimony | 0.00% | 0.00% | 0.00% | 94.6% lead | 70.0 lbs | 12.2 bhn |

1olbs of foundry lead with out shopping around will run you $50 mixed with the pure you get 70lbs you now have a nice alloy for under $1/lb not to bad.

you would need close to 50/50 mix of Lyman #2 to get to 12bhn or $180 worth of lyman #2 to get 120lbs of alloy which will bring your over all price for your alloy down 10 cents a pound or so

Either way its not a bad way to get a decent little stock pile of alloy you would like. 120lbs will give you 6000 or so 124 grain cast bullets ? Lets just say it cost you $200 to make this alloy thats about .03 cents a bullet add a little propane ( I can smelt and blend aprox 500lbs on one 15lb blue rhino tank) Still cheap and fun.

Wheel weight alloy is not as hard as it used to be also theres very little if any tin these days (lead clips ons made in the last 20 years or so) Tin is just to expensive to bother in wheel weights.

So even if you get wheel weight alloy your still going to need a 40/60 blend to get the hardness up.

40 Flashing 60 wheel weight

Get a set of art pencils and test your flashing to get an idea of the hardness.

If you know your bhn you can use this simple formula to get decent results to start blending. I could be completely wrong also?

View: https://www.youtube.com/watch?v=7Y0raK6_Vbk

Last edited:

Lank

NES Member

you could, you dont know the alloy content of the flashing. Flashing could be pure and or have Antimony in it. If your going to use a bottom pour pot for casting its a good idea to smelt and clean up you alloy before you run it through the pot. If your going to ladle pour your mold you could do it in your pot. Thing is if your going to be making up alloys doing it by the 10lb pund pot is not very efficient. Depends on what you want out of it I guess.

Heres my thoughts

your looking for what 12 bhn or so

assume your flashing is 5 BHN 60 lbs you could go with 10lbs of Foundry type lead and have

tin Antimony lead lbs Bhn

1olbs of foundry lead with out shopping around will run you $50 mixed with the pure you get 70lbs you now have a nice alloy for under $1/lb not to bad.

you would need close to 50/50 mix of Lyman #2 to get to 12bhn or $180 worth of lyman #2 to get 120lbs of alloy which will bring your over all price for your alloy down 10 cents a pound or so

Either way its not a bad way to get a decent little stock pile of alloy you would like. 120lbs will give you 6000 or so 124 grain cast bullets ? Lets just say it cost you $200 to make this alloy thats about .03 cents a bullet add a little propane ( I can smelt and blend aprox 500lbs on one 15lb blue rhino tank) Still cheap and fun.

Wheel weight alloy is not as hard as it used to be also theres very little if any tin these days (lead clips ons made in the last 20 years or so) Tin is just to expensive to bother in wheel weights.

So even if you get wheel weight alloy your still going to need a 40/60 blend to get the hardness up.

40 Flashing 60 wheel weight

Get a set of art pencils and test your flashing to get an idea of the hardness.

If you know your bhn you can use this simple formula to get decent results to start blending. I could be completely wrong also?

View: https://www.youtube.com/watch?v=7Y0raK6_Vbk

This is very helpful! Many thanks

Just be sure to double check any calculations I spew out. Often they are at times when im distracted tired or relying on memory- often all at the same time!This is very helpful! Many thanks

Its easier too add to a soft alloy to bring up BHN than taking away from a harder BHN to make it softer.

You could also use magnum lead shot which you might find locally theres no tin in lead shot though ?

Start the hunt for lead. it takes a little time

try your best to figure out what you have

Checking Lead Hardness With Drawing Pencils

I thought that this information would be interesting to a lot of you readers. A month or so ago I

Look for pewter at thrift stores, odd ends of solder at yard sales, old fishing weights ect ect.

alot of what we do is "close enough work" in that video his Linotype is 3 points harder than on the alloy calculator im useing. If I input his numbers into the calculator it comes up with 13.7Bhn

Now I can only change the data in yellow so I cant change the Bhn to see how things change, but you know that guy in the video is a lefty so his calculations have to be right or GEN (Good E Nuff)

Last edited:

Just be sure to double check any calculations I spew out. Often they are at times when im distracted tired or relying on memory- often all at the same time!

Its easier too add to a soft alloy to bring up BHN than taking away from a harder BHN to make it softer.

You could also use magnum lead shot which you might find locally theres no tin in lead shot though ?

Start the hunt for lead. it takes a little time

try your best to figure out what you have

Checking Lead Hardness With Drawing Pencils

I thought that this information would be interesting to a lot of you readers. A month or so ago Iwww.castbulletassoc.org

Look for pewter at thrift stores, odd ends of solder at yard sales, old fishing weights ect ect.

alot of what we do is "close enough work" in that video his Linotype is 3 points harder than on the alloy calculator im useing. If I input his numbers into the calculator it comes up with 13.7Bhn

Now I can only change the data in yellow so I cant change the Bhn to see how things change, but you know that guy in the video is a lefty so his calculations have to be right or GEN (Good E Nuff)

View attachment 363085

I like the Arrow T-50 3/8" staple method also- I think I'll try that.

Many thanks to @Michael J. Spangler , @mac1911 , and to anyone else who has contributed answers or further questions. This is turning out to be a great thread and reminds me what a great resource NES can be.

![Thumbs Up [thumbsup] [thumbsup]](/xen/styles/default/xenforo/smilies.vb/044.gif)

38ExtraSpecial

NES Member

Happy to help! We need to share and keep casting alive.I like the Arrow T-50 3/8" staple method also- I think I'll try that.

Many thanks to @Michael J. Spangler , @mac1911 , and to anyone else who has contributed answers or further questions. This is turning out to be a great thread and reminds me what a great resource NES can be.![Thumbs Up [thumbsup] [thumbsup]](/xen/styles/default/xenforo/smilies.vb/044.gif)

are you using the old school stapler or one of those super easy squeeze ones ?I like the Arrow T-50 3/8" staple method also- I think I'll try that.

Many thanks to @Michael J. Spangler , @mac1911 , and to anyone else who has contributed answers or further questions. This is turning out to be a great thread and reminds me what a great resource NES can be.![Thumbs Up [thumbsup] [thumbsup]](/xen/styles/default/xenforo/smilies.vb/044.gif)

f***ing stable guns! I always end up with the wrong size gun and staples.... I said to myself a few years ago I would ditch all the "others" ( T27 staples)and just keep a few T-50s around.... I had a T25 and T75 that shot those heavy duty wire staples and another model that shot insulated stables....from back when I worked with my dad 30 plus years ago. Dont see those staples in stock much these days. Heck I dont even know where those guns are. Berried in some tool box somewhere

toss the T-2 serries out , leave it at the gun club for the fudds to take home.I have an old T-50 and also have a T-25 that needs some attention- jamming too much. I have a newer one similar to a T-50 but different brand, have to look.

Just ordered the NOE 403-198 mold and decided to go with the hollow point version which will kill 2 birds with one mold, LOL. I can make the heavy hard cast plus the HP version at a lower weight and softer alloy. While I was at it, I checked NOE's Faceplant page which had a link to Taco's 458 SOCOM test of self cast NOE's. So I ordered a 459-300 mold as well. I chickened out a little for both and decided to run gas checks.

Yeah, I'm going to need a lot of lead...

Yeah, I'm going to need a lot of lead...

I run gas checks on any bullet designed for them , even most of my 50 yard plinker stuff? I have a few plain base bullets for most of that stuff now.Just ordered the NOE 403-198 mold and decided to go with the hollow point version which will kill 2 birds with one mold, LOL. I can make the heavy hard cast plus the HP version at a lower weight and softer alloy. While I was at it, I checked NOE's Faceplant page which had a link to Taco's 458 SOCOM test of self cast NOE's. So I ordered a 459-300 mold as well. I chickened out a little for both and decided to run gas checks.

Yeah, I'm going to need a lot of lead...

300 grain slugs take up a lot of volume! 23 per pound--- man when you start looking at some numbers it can be a bit deflating BUT think how inexpensive your 458 socom becomes to plink with

whats cheap 458 go for $1.40 rd ? Probably run you .40 cents plus to buy cast .50 or more for jacketed ? money saver there if you get lead cheap and free brass. I consider the brass free after you shoot any factory ammo you bought.

38ExtraSpecial

NES Member

I’m of the opposite mindset with GCs. I don’t like spending the money at all. Seems a waste with the coating and quality lubes available now. What I try to do is to run a heavy for caliber bullet which gives me the most oomph for the cartridge while still staying under the velocity at which cast can run into issues.I run gas checks on any bullet designed for them , even most of my 50 yard plinker stuff? I have a few plain base bullets for most of that stuff now.

300 grain slugs take up a lot of volume! 23 per pound--- man when you start looking at some numbers it can be a bit deflating BUT think how inexpensive your 458 socom becomes to plink with

whats cheap 458 go for $1.40 rd ? Probably run you .40 cents plus to buy cast .50 or more for jacketed ? money saver there if you get lead cheap and free brass. I consider the brass free after you shoot any factory ammo you bought.

Sure I use up a little more lead but generally I use a little less powder also.

Just another way to skin the cat.

I just have it stuck in my head that that bevel lets the chance of more gas checking to start its way in.? Plus I have had zero leading issues doing it this way so im hooked. I wont be coating anytime soon its going to be the way for me.I’m of the opposite mindset with GCs. I don’t like spending the money at all. Seems a waste with the coating and quality lubes available now. What I try to do is to run a heavy for caliber bullet which gives me the most oomph for the cartridge while still staying under the velocity at which cast can run into issues.

Sure I use up a little more lead but generally I use a little less powder also.

Just another way to skin the cat.

38ExtraSpecial

NES Member

I haven’t had issue with things like 38 special. Maybe with hotter loads. Then I coat so it kind of negates the need for GC. Given my preference I would go coating and plain baseI just have it stuck in my head that that bevel lets the chance of more gas checking to start its way in.? Plus I have had zero leading issues doing it this way so im hooked. I wont be coating anytime soon its going to be the way for me.

I run gas checks on any bullet designed for them , even most of my 50 yard plinker stuff? I have a few plain base bullets for most of that stuff now.

300 grain slugs take up a lot of volume! 23 per pound--- man when you start looking at some numbers it can be a bit deflating BUT think how inexpensive your 458 socom becomes to plink with

whats cheap 458 go for $1.40 rd ? Probably run you .40 cents plus to buy cast .50 or more for jacketed ? money saver there if you get lead cheap and free brass. I consider the brass free after you shoot any factory ammo you bought.

I'm going to jinx myself for mentioning this, but I've run several reloads through a few groups of Starline .458 brass with no issues so far. Most I had to work it was when new- the shoulder had to be brought back. I've been able to get 300 gr Hornady JHP's on sale for fairly cheap and they run great for me. When the rifle was new I had a couple hiccups with 325 gr FTX's with the soft plastic tip. No issues lately with those but the JHP's are way cheaper and devastating on targets like pumpkins. The cast HP's should provide the same level of stupid fun.

I’m of the opposite mindset with GCs. I don’t like spending the money at all. Seems a waste with the coating and quality lubes available now. What I try to do is to run a heavy for caliber bullet which gives me the most oomph for the cartridge while still staying under the velocity at which cast can run into issues.

Sure I use up a little more lead but generally I use a little less powder also.

Just another way to skin the cat.

I did give it some thought and decided it was definitely a good idea for the .458 being a semi and getting some decent velocity from 300's. Probably could have gone plain mold for the 10mm but with the HP pins I think they will be maybe ~175 or 180 grains? Either type should be OK in the KKM barrel w/ standard rifling but I'll feel better running hotter loads with GC's in the factory Glock barrel.

38ExtraSpecial

NES Member

Run them GC and run some coated without and see how they do.I'm going to jinx myself for mentioning this, but I've run several reloads through a few groups of Starline .458 brass with no issues so far. Most I had to work it was when new- the shoulder had to be brought back. I've been able to get 300 gr Hornady JHP's on sale for fairly cheap and they run great for me. When the rifle was new I had a couple hiccups with 325 gr FTX's with the soft plastic tip. No issues lately with those but the JHP's are way cheaper and devastating on targets like pumpkins. The cast HP's should provide the same level of stupid fun.

I did give it some thought and decided it was definitely a good idea for the .458 being a semi and getting some decent velocity from 300's. Probably could have gone plain mold for the 10mm but with the HP pins I think they will be maybe ~175 or 180 grains? Either type should be OK in the KKM barrel w/ standard rifling but I'll feel better running hotter loads with GC's in the factory Glock barrel.

worst case scenario if you don’t need the GC you find a local machine shop or send it out to hollowpointmolds to have the gas check shank removed.No biggie.

Share: