- Joined

- Jul 2, 2023

- Messages

- 114

- Likes

- 70

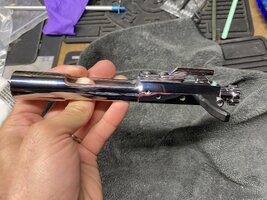

Can someone please explain the differences between Phosphate, Black Nitride, and Nickel Boron? The price difference within the same brand is nominal at best. Which one is better?

I ordered my lower today and am now pricing out the rest of the parts. I have my eye on a few BCG brands but am at a loss regarding the coating afford on them. In a similar situation with triggers but that's a whole different conversation

I ordered my lower today and am now pricing out the rest of the parts. I have my eye on a few BCG brands but am at a loss regarding the coating afford on them. In a similar situation with triggers but that's a whole different conversation