-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

-

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Am I crazy?

- Thread starter SmoothDatadan

- Start date

ReluctantDecoy

NES Member

Of course it matters. How else would you display a smug sense of unearned entitlement to flex over poors?

The problem with Anderson lowers is they are often out of spec. If you get one in spec, you are good to go. That said, the fit between the lower and upper should be tight enough that they don't wiggle, otherwise it won't matter how accurate your upper is.

Cap

NES Member

The problem with Anderson lowers is they are often out of spec. If you get one in spec, you are good to go. That said, the fit between the lower and upper should be tight enough that they don't wiggle, otherwise it won't matter how accurate your upper is.

Define wiggle.

ReluctantDecoy

NES Member

The problem with Anderson lowers is they are often out of spec. If you get one in spec, you are good to go. That said, the fit between the lower and upper should be tight enough that they don't wiggle, otherwise it won't matter how accurate your upper is.

There are so many companies making uppers and lowers though, who's to say it isn't the upper?

tuna

NES Member

To make everyone think they are the .01% that can wring the difference out of the gun.Mated a S&W Sport lower to a BCM Upper, no problems. Why do people worry about this?

If you’re not a true sub MOA shooter or stone cold operator, it shouldn’t make a difference.

Not an AR fan, but every now and then I get the urge. The poverty ponies look real good at free state prices.

Then I get better and go look at revolvers. Lol

Ah but there are differences. The mag well is one place where you may see that. I have Andersons that won't take a 9mm adapter block because the rib in the mag well isn't machined correctly.So long as the holes are the right size and properly located, a lower is a lower is a lower and doesn't affect the shootability of the gun,

It takes a standard mag ok though.

Details.

"Often" is internet nonsense that gets repeated over and over. I've built on several Anderson receivers and none had issues. I know many others who have used Anderson receivers with zero issues and have heard zero complaints directly from the source. Not saying they have never shipped something that's off- but I've only seen internet "experts" complain.The problem with Anderson lowers is they are often out of spec. If you get one in spec, you are good to go. That said, the fit between the lower and upper should be tight enough that they don't wiggle, otherwise it won't matter how accurate your upper is.

You MIGHT find an upper and lower set that do not wiggle a LOT, but all will have some built in tolerance. "In spec" means mil spec, and if truly mil spec there's going to be a little tolerance there. If a receiver set fits tightly together, sure I'd like that- but in reality that's not "in spec". Little O-ring over the rear trunnion, squeeze shut, push in pin. No wiggle for pennies and better than the little red wedges.

True- it won't make a difference. In fact, if I considered myself an operator I'd want components with a little tolerance to ensure interchangeability with my fellow mall ninjas I mean operators. For the AR's we would use for home defense, I could care less about the upper and lower fit so long as not too tight. Also for self defense NFW would I use some boutique receiver set machined from billet. The forging process reliably creates some inherent strength and there is only a small handful of experienced forge shops that produce the raw forgings for the various AR suppliers.To make everyone think they are the .01% that can wring the difference out of the gun.

If you’re not a true sub MOA shooter or stone cold operator, it shouldn’t make a difference.

Not an AR fan, but every now and then I get the urge. The poverty ponies look real good at free state prices.

Then I get better and go look at revolvers. Lol

For the paper punching games I like to play I have a Compass Lake upper, a White Oak, and a fugly abomination that I built around a Criterion barrel for CMP "Games". All are sub-moa if I use decent glass on them and use a nice match trigger in the lower. Make of the receivers has 0% effect on accuracy.

that`s why smart people with brains get 39 of them, presumably.I have personally seen an Anderson lower that was out of spec. Trigger pin holes not drilled properly. Built one for a neighbor. Not “nonsense “

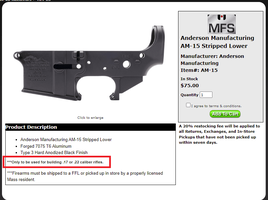

MFS sells those lowers right now, for $79 - you just need to tell you will build a .22lr...

JRT

NES Member

All of the cheap stuff is forged, CNC’ed lowers start at a few hundred bucks, or is this a humblebrag?With the way they are CNC machined these days, I think you'd be hard pressed to find one. I've bought a few cosmetic BLEM upper and lowers over the years but all were in spec dimension wise and I had a hard time even picking out what the company called a BLEM. A different shade on the anodizing wouldn't bother me a bit, it would probably get dinged in handling and use anyway. If it gets too dinged up, it gets a rattle can camo paint job.

cockpitbob

NES Member

ReluctantDecoy

NES Member

FearOK, that seems weird. Can someone enlighten me? What's behind that restriction?

View attachment 609627

ReluctantDecoy

NES Member

All of the cheap stuff is forged, CNC’ed lowers start at a few hundred bucks, or is this a humblebrag?

Also, CNC might be precise in theory, but it all comes down to machine tolerances, end mill state, and quality of initial CAD and machine code. CNC is not infallible just because of the computer aspect.

just put your paw to the heart at the store, look them in the eye and say in your nicest way 'scouts honor!'.OK, that seems weird. Can someone enlighten me? What's behind that restriction?

View attachment 609627

Of course it matters. How else would you display a smug sense of unearned entitlement to flex over poors?

That's about the true extent of it.^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif)

Rimfire ≠ AWBOK, that seems weird. Can someone enlighten me? What's behind that restriction?

View attachment 609627

Asaltweapon

NES Member

No beard grows here.I'm Irish and Polish. Beard growth??? 55% of 0 is still 0.

I put a 200 tax stamp on my Anderson lower. So stripped it’s now worth $249.00. That’s the same price as I’ve seen on some ads here.

All of the cheap stuff is forged, CNC’ed lowers start at a few hundred bucks, or is this a humblebrag?

Commercially produced AR receivers are CNC machined, whether billet or forged.

Forged receivers are actually stronger than billet because the metal is work hardened during forging.

Here is a comparison chart on the differences:

| Alloy and Temper | Form | Thickness | Material Properties* (KSI unless noted) | ||||||||

| Ultimate Tensile Strength Ftu | Yield Tensile Strength Fty | Yield Comp. Strength Fcy | Ultimate Shear Strength Fsu | Ultimate Bearing Strength Fbru e/D=1.5 | Yield Bearing Strength Fbry e/D=1.5 | Modulus of Elasticity E x103 | |||||

| 7075-T6 | Billet | 1.001 – 2.000 | 77 | 66 | 64 | 46 | 100 | 86 | 10.3 | ||

| 7075-T6 | Die Forging | 1.001 – 2.000 | 74 | 63 | 66 | 43 | 104 | 82 | 10.0 | ||

| 6061-T6 | Billet | 1.001 – 6.500 | 38 | 35 | 34 | 19 | 52 | 42 | 9.9 | ||

| 6061-T6 | Die Forging | ≤ 4.000 | 38 | 35 | 36 | 25 | 61 | 54 | 9.9 | ||

| * – Data taken from DOT/FAR/AR-MMPDS-01 Metallic Materials Properties Development & Standardization, 31 January 2003 |

What is the Machined or Billet?

Machined lower receivers are cut form a solid block of aluminum 7075-T6. The block of raw aluminum if often refereed to as billet. Think of the billet as a block of wood that through chisels or knives you would whittle into a shape. Instead of chisels CNC machines are used to precession cut the block to match a 3d computer model.How is Forged Different?

Forged lowers take a billet block of aluminum and heat the aluminum to 1/3rd of its melting point making it soft. A mold is then used to press the heated billet into a specific form. This is done using a very heavy several tons of pressure press that can stamp out forged items very fast. There is usually a bit of metal that seeps between the halves of the mold that needs to be trimmed off or smoothed out.Which is Stronger?

Forged is generally thought to be stronger as you can see in the chart above. The reason for this is when metal cools it forms grains that do not stick together well. The forging process presses those grains together tighter creating a stronger bond and also pushes those grains into a specific pattern that can be used to strengthen the points that receive the most pressure.The real truth of it is though is evident in the diagram above. There is very little difference in any of the strength values between the forged and the machined parts. The real difference in strength is related to the type of alloy and the form of temper. So if your concern is durability any lower in 7075-T6 aluminum is likely to meet your needs.

Why Does Machined Cost More?

Billet lowers are usually substantially more money then forged lowers. The reason for this is in the manufacturing process, not the strength or quality of the end product.Remember a machined lower starts with an entire billet block larger than the end product. The block is then reduced down by shaving and cutting the block to the desired specs. The left over aluminum is more or less wasted. Yes it is sold as scrap but when compared to the amount of aluminum used in the forging process you are wasting a lot of metal.

Second the machining process takes a very expensive CNC machine that needs to move the parts around and cut away the parts. The moving of the block and cutting process takes much more time then the simple forged stamping process. Further the cutting blades are expensive and must be kept cool or they will melt.

With forging once the expensive machine is purchased and an initial model is made the cost of operation is very low and the production rate is incredibly high. Forging is like a factory where CNC is like a custom shop. You always pay more for custom since time and materials is money.

Why Does Anyone Buy Machined?

Forging is stronger and cheaper so you are probably wondering why are so many companies selling billet lowers and why would I buy one? Looks are the largest reason. Forged lowers can not have hard 90 degree angles without additional machining, they also tend to have a more rounded look with less straight lines. They tend to be far less adorned then Machined work due to the mass produced nature of the product.Forged parts require a new mold when changing your product line or adding new features like a different trigger guard or magazine well . This results in shutting down the line to re-tool as well. With CNC machining it is just a matter of running a different program. This makes CNC manufacturing very adaptable to market demand and a wider range of marketable products.

So Which One do I Want?

Honestly I do not know. Don’t you hate that answer when you read a blog. The fact is I can’t answer that for you. All I can do is give you the facts to make a better decision. The answer comes down to what are you using it for, how much do you want to spend, and how important are looks?My recommendation is go 7075-T6 aluminum. If your budget conscious or really going to beat the hell out of your gun go forged. If you have the money and want the look of some awesome great lines then spend the cash on the billet lower designed the way you want.

I really like the looks of some of the high end Billet lowers that companies like Spikes Tactical and Seekins make. Here are some examples

Image:248Shooter.Com

Image:248Shooter.Com  Image:248Shooter.Com

Image:248Shooter.Com  Image:248Shooter.Com

Image:248Shooter.ComThis article originally published at www.248shooter.com

Featured photo courtesy of Aero Precision

Source Article from http://feedproxy.google.com/~r/TheArmsGuide/~3/zeCwDDONhkY/

JRT

NES Member

Interesting, in my mind forged and billet meant something different. I had billet down properly but forged was not what I thought it was. Never to old to learn I guess.Commercially produced AR receivers are CNC machined, whether billet or forged.

Forged receivers are actually stronger than billet because the metal is work hardened during forging.

Here is a comparison chart on the differences:

Alloy

and

TemperForm Thickness Material Properties* (KSI unless noted) Ultimate

Tensile

Strength

FtuYield

Tensile

Strength

FtyYield

Comp.

Strength

FcyUltimate

Shear

Strength

FsuUltimate

Bearing

Strength

Fbru

e/D=1.5Yield

Bearing

Strength

Fbry

e/D=1.5Modulus

of

Elasticity

E

x1037075-T6 Billet 1.001 – 2.000 77 66 64 46 100 86 10.3 7075-T6 Die Forging 1.001 – 2.000 74 63 66 43 104 82 10.0 6061-T6 Billet 1.001 – 6.500 38 35 34 19 52 42 9.9 6061-T6 Die Forging ≤ 4.000 38 35 36 25 61 54 9.9 * – Data taken from DOT/FAR/AR-MMPDS-01 Metallic Materials Properties Development & Standardization, 31 January 2003 What is the Machined or Billet?

Machined lower receivers are cut form a solid block of aluminum 7075-T6. The block of raw aluminum if often refereed to as billet. Think of the billet as a block of wood that through chisels or knives you would whittle into a shape. Instead of chisels CNC machines are used to precession cut the block to match a 3d computer model.

How is Forged Different?

Forged lowers take a billet block of aluminum and heat the aluminum to 1/3rd of its melting point making it soft. A mold is then used to press the heated billet into a specific form. This is done using a very heavy several tons of pressure press that can stamp out forged items very fast. There is usually a bit of metal that seeps between the halves of the mold that needs to be trimmed off or smoothed out.

Which is Stronger?

Forged is generally thought to be stronger as you can see in the chart above. The reason for this is when metal cools it forms grains that do not stick together well. The forging process presses those grains together tighter creating a stronger bond and also pushes those grains into a specific pattern that can be used to strengthen the points that receive the most pressure.

The real truth of it is though is evident in the diagram above. There is very little difference in any of the strength values between the forged and the machined parts. The real difference in strength is related to the type of alloy and the form of temper. So if your concern is durability any lower in 7075-T6 aluminum is likely to meet your needs.

Why Does Machined Cost More?

Billet lowers are usually substantially more money then forged lowers. The reason for this is in the manufacturing process, not the strength or quality of the end product.

Remember a machined lower starts with an entire billet block larger than the end product. The block is then reduced down by shaving and cutting the block to the desired specs. The left over aluminum is more or less wasted. Yes it is sold as scrap but when compared to the amount of aluminum used in the forging process you are wasting a lot of metal.

Second the machining process takes a very expensive CNC machine that needs to move the parts around and cut away the parts. The moving of the block and cutting process takes much more time then the simple forged stamping process. Further the cutting blades are expensive and must be kept cool or they will melt.

With forging once the expensive machine is purchased and an initial model is made the cost of operation is very low and the production rate is incredibly high. Forging is like a factory where CNC is like a custom shop. You always pay more for custom since time and materials is money.

Why Does Anyone Buy Machined?

Forging is stronger and cheaper so you are probably wondering why are so many companies selling billet lowers and why would I buy one? Looks are the largest reason. Forged lowers can not have hard 90 degree angles without additional machining, they also tend to have a more rounded look with less straight lines. They tend to be far less adorned then Machined work due to the mass produced nature of the product.

Forged parts require a new mold when changing your product line or adding new features like a different trigger guard or magazine well . This results in shutting down the line to re-tool as well. With CNC machining it is just a matter of running a different program. This makes CNC manufacturing very adaptable to market demand and a wider range of marketable products.

So Which One do I Want?

Honestly I do not know. Don’t you hate that answer when you read a blog. The fact is I can’t answer that for you. All I can do is give you the facts to make a better decision. The answer comes down to what are you using it for, how much do you want to spend, and how important are looks?

My recommendation is go 7075-T6 aluminum. If your budget conscious or really going to beat the hell out of your gun go forged. If you have the money and want the look of some awesome great lines then spend the cash on the billet lower designed the way you want.

I really like the looks of some of the high end Billet lowers that companies like Spikes Tactical and Seekins make. Here are some examples

Image:248Shooter.Com

Image:248Shooter.Com

Image:248Shooter.Com

This article originally published at www.248shooter.com

Featured photo courtesy of Aero Precision

Source Article from http://feedproxy.google.com/~r/TheArmsGuide/~3/zeCwDDONhkY/

OK, that seems weird. Can someone enlighten me? What's behind that restriction?

View attachment 609627

Is $75 for that lower a "free state price" ?

I was under the assumption according to NES classifieds, a "free state price" for a run of the mill lower was $150...

Now I am more confused than I am normally.

ReluctantDecoy

NES Member

True. They didn't specify LR or short.Can an argument be made that a .223 or 5.56 round is a .22 caliber?

From the "enforcement notice"...Can an argument be made that a .223 or 5.56 round is a .22 caliber?

"The following are examples of weapons that are not copies or duplicates of enumerated weapons under G.L. c. 140 §121: any .17 or .22 caliber rimfire rifle;"

Asaltweapon

NES Member

My SBR Anderson with a WW upper wiggled about the same, maybe a tad less than my 100% factory LMT.Define wiggle.

I never measured it.

cathouse01

NES Member

- Joined

- May 10, 2018

- Messages

- 2,444

- Likes

- 4,671

And the idiots actually did have to reissue the original enforcement notice because it did just have “.22 caliber” (did not include the rimfire).From the "enforcement notice"...

"The following are examples of weapons that are not copies or duplicates of enumerated weapons under G.L. c. 140 §121: any .17 or .22 caliber rimfire rifle;"

Share:

Similar threads

- Replies

- 22

- Views

- 502

- Replies

- 12

- Views

- 332