-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

-

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do in the shack today?

- Thread starter CatSnoutSoup

- Start date

ToddDubya

NES Member

Welcome to amateur radio!Passed my tech test yesterday

ToddDubya

NES Member

I was having some trouble with what sounded like scratchy CW sending today with a particular key. When I use a paddle I don't get it, and when I use the paddle in straight key mode I don't get it, but then when I go back to this particular key it's scratchy again. The way the contacts work is it's just the polished ends of two machine screws (one being the one I just replaced). I think what I thought was dirty/rough contacts might be something else. When I polished the new screw I intentionally tried to round the face a little so if it wasn't perfectly square to the other screw it would still make a clean contact. I've used paper between the contacts to try and clean it, but it just comes out clean every time.

I just tried with my J-38 key and that sounds just fine too.

Anyone got any ideas?

I just tried with my J-38 key and that sounds just fine too.

Anyone got any ideas?

Welcome xtry51!!! Congrats!!!Passed my tech test yesterday

It almost sounds like the current path from one terminal to the other through the contacts has something loose. Are the machine screws/contacts in a tight threaded hole. As they contact each other, I wonder if there is the slightest bit of movement between the machine screw threads and the holes they are threaded into creating an ever so slight break of contact.I was having some trouble with what sounded like scratchy CW sending today with a particular key. When I use a paddle I don't get it, and when I use the paddle in straight key mode I don't get it, but then when I go back to this particular key it's scratchy again. The way the contacts work is it's just the polished ends of two machine screws (one being the one I just replaced). I think what I thought was dirty/rough contacts might be something else. When I polished the new screw I intentionally tried to round the face a little so if it wasn't perfectly square to the other screw it would still make a clean contact. I've used paper between the contacts to try and clean it, but it just comes out clean every time.

I just tried with my J-38 key and that sounds just fine too.

Anyone got any ideas?

ToddDubya

NES Member

That's what it sounds like. Not much I can do there. Maybe add some dielectric grease?It almost sounds like the current path from one terminal to the other through the contacts has something loose. Are the machine screws/contacts in a tight threaded hole. As they contact each other, I wonder if there is the slightest bit of movement between the machine screw threads and the holes they are threaded into creating an ever so slight break of contact.

ChevyGuy91

NES Member

- Joined

- Mar 25, 2008

- Messages

- 22,947

- Likes

- 23,599

Throw a big antenna up and let's see if we can work a 2m machine.Passed my tech test yesterday

Throw a big antenna up and let's see if we can work a 2m machine.

I have an IC-705 and accouterments on a shelf in the basement I need to setup.

No, I would use a tiny bit of conductive (anti-seize copper?) grease or something like that...you could also use a double nut (jam nut) once you get the spacing right and tighten it up. If you look at your J38, there is a wider finger nut under the contact spacing adjustment screw head. That keeps the contact spaced correctly and keeps the contact from wobbling which would do what you describe.That's what it sounds like. Not much I can do there. Maybe add some dielectric grease?

ToddDubya

NES Member

After probing all over the place on it, I kept seeing the resistance in the ground path suddenly jump to 25, 50 ohms, sometimes up to OL. Some more sleuthing and it turned out to be that the pivot pin, which is part of the return path, was not very conductive. I cleaned it up and slathered it with dielectric grease and I think I'm in business. I hope this doesn't become a regular maintenance thing.It almost sounds like the current path from one terminal to the other through the contacts has something loose. Are the machine screws/contacts in a tight threaded hole. As they contact each other, I wonder if there is the slightest bit of movement between the machine screw threads and the holes they are threaded into creating an ever so slight break of contact.

The pin is on the left in this picture, and connects the black arm to the red base.

I was wondering about that...whatever you use, it needs to be conductive...Ox Guard is just that. When I got my J38 many (many!) years ago, it was doing what you described and I kept cleaning the contacts to no effect. I finally figured out that, like what you found, the pivots were dirty and they are part of the current path in that key. I ended up cleaning the key pivot points with CAIG D5 DeOxit and with a Q-tip did the same thing with the part of the frame that the pivot points set into. I dabbed a bit of conductive grease onto the pivot points and It's been problems free ever since.Maybe I'm not using the right word. It's the grease I put on my coax connectors to keep them from corroding and keep water out. It's conductive.

Ox Gard

UJay

NES Member

Local buddies attempting to motivate me for the VHF contest this weekend - it kindof worked...Dusted off the TS-2000.

1 section + 1 pointy top Rohn45 up and guyed with 5el 6m and freshly repaired 11el 2m beam ready to go up when the snow lets up tomorrow or weds....

Wired up a (T2x) rotor and tested. It will go in the tower after 2m is up there.

Stuff works better lightly planned and cold wx.

UJay

1 section + 1 pointy top Rohn45 up and guyed with 5el 6m and freshly repaired 11el 2m beam ready to go up when the snow lets up tomorrow or weds....

Wired up a (T2x) rotor and tested. It will go in the tower after 2m is up there.

Stuff works better lightly planned and cold wx.

UJay

UJay

NES Member

Got the 2m beam repaired, swept and on the tower today,

The driven element is from a 3el FM yagi. broadband, but high in the band. SWR is ~1.6:1 at 144.2

Found an old ~100' piece of 1/2 heliax and deployed it for the 2m beam.

Decoded Chile on 6m those are pointed about due south now-

Should have added another 10' section.....

Ran out of light.

left TODO;

Align the 2m with the 6m and push the 2m up the mast as far as I can reach

Raise the mast and throw in the rotor in there -- Hanging off of the tower now.

Wire up the rotor controller in the shack.

UJay

The driven element is from a 3el FM yagi. broadband, but high in the band. SWR is ~1.6:1 at 144.2

Found an old ~100' piece of 1/2 heliax and deployed it for the 2m beam.

Decoded Chile on 6m those are pointed about due south now-

Should have added another 10' section.....

Ran out of light.

left TODO;

Align the 2m with the 6m and push the 2m up the mast as far as I can reach

Raise the mast and throw in the rotor in there -- Hanging off of the tower now.

Wire up the rotor controller in the shack.

UJay

ToddDubya

NES Member

Beautiful weather for it.Got the 2m beam repaired, swept and on the tower today,

The driven element is from a 3el FM yagi. broadband, but high in the band. SWR is ~1.6:1 at 144.2

Found an old ~100' piece of 1/2 heliax and deployed it for the 2m beam.

View attachment 840133View attachment 840132

Decoded Chile on 6m those are pointed about due south now-

Should have added another 10' section.....

Ran out of light.

left TODO;

Align the 2m with the 6m and push the 2m up the mast as far as I can reach

Raise the mast and throw in the rotor in there -- Hanging off of the tower now.

Wire up the rotor controller in the shack.

UJay

That 2m beam looks like it should offer some gain, and a 5 el 6m yagi is no slouch either. Nice stuff you got there.

UJay

NES Member

Thanks man... The 6m Beam was procured in ~2007 and taken down in 2010 to move to multiop club station and then ended up back here last week. Club station disassembled...Beautiful weather for it.

That 2m beam looks like it should offer some gain, and a 5 el 6m yagi is no slouch either. Nice stuff you got there.

The 2m was put together with from 4 broken 2m antennas. 11el Cushcraft... It is pretty rusty. New feedpoint and newest looking driven element with fattest tube for bandwidth.

If you like these, waitll' you see the HF antenna. I can't even imagine the size it is going to be. In boxes in the basement now, springtime install. 33' square boom.

I finished the VHF tower today... Squared up the beams and aimed them the best I could and rotor controller working great (Keyboard keystroke turns the antenna to desired azimuth.. )

All is well.. I think after this weekend I am going to take down the 2m ant and put up a 10m ant..... But must admit; 2m is pretty fun with 11el... 1st QSO was Maine FN53 and 2nd was FN20. I'm in FN42.

UJay

ToddDubya

NES Member

My buddy and elmer in FN32 will be doing the VHF/UHF contest this weekend. I think he just put up an 11 el yagi for 2m. He used to be a rover all the time and is slowly getting back into it. I think I might have let him down when I didn't jump at the chance to join him. He does up to 10GHz. I think he makes more contacts bouncing off of storms and water towers than he does direct line of sight.

ToddDubya

NES Member

The aforementioned elmer has 6m, 2m, 1.25m if you're looking this weekend. I think he'll be working the contest on Saturday but not Sunday. FN32.

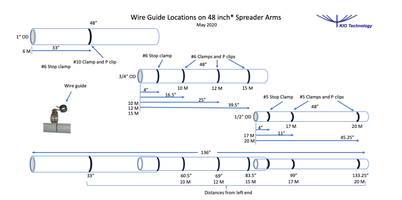

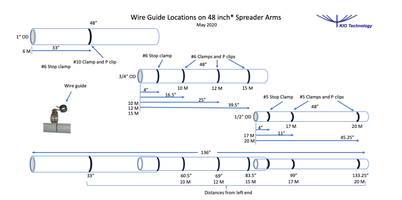

I picked up some 6' driveway markers today and I'm going to replace the 4' garden stakes I used for my hex beam. This way I can fit 6m and 10m on the same spreaders, maybe even 12m (probably not at the same time). I cut the wires and assembled the wiring harness (radiating element #1, spacer, reflector, spacer, radiating element #2) so all I have to do tomorrow is swap out the stakes and assemble. I trusted the specs I found here, so hopefully they're good. Specs | Build your own Hex Beam

I should make up some hooks or something I can tape to the spreaders to make assembly quick and repeatable. Whatever I did before worked but it was a hassle and is not easily repeatable. I'm thinking this could be very portable if I'm smart about it.

My wire measuring board has to be one of the handiest gadgets I've made in years. The smart move was marking tenths of a foot, so I don't have to convert to inches. I needed a wire 17' long - just wrap it around 17 times and Bob's your uncle. Same for the driven elements at 8.9'.

For spacers, I just took some paracord maybe 14" long and used glue lined heat shrink to attach it to the end of one wire. Then measure carefully to get 12" spacing, and heat shrink the other end. There's no real tension on the wires so this should be plenty strong.

Based on this diagram, my 72" driveway markers should let me get up to 12m. We'll see. 6m was surprisingly short, so I'm optimistic.

I picked up some 6' driveway markers today and I'm going to replace the 4' garden stakes I used for my hex beam. This way I can fit 6m and 10m on the same spreaders, maybe even 12m (probably not at the same time). I cut the wires and assembled the wiring harness (radiating element #1, spacer, reflector, spacer, radiating element #2) so all I have to do tomorrow is swap out the stakes and assemble. I trusted the specs I found here, so hopefully they're good. Specs | Build your own Hex Beam

I should make up some hooks or something I can tape to the spreaders to make assembly quick and repeatable. Whatever I did before worked but it was a hassle and is not easily repeatable. I'm thinking this could be very portable if I'm smart about it.

My wire measuring board has to be one of the handiest gadgets I've made in years. The smart move was marking tenths of a foot, so I don't have to convert to inches. I needed a wire 17' long - just wrap it around 17 times and Bob's your uncle. Same for the driven elements at 8.9'.

For spacers, I just took some paracord maybe 14" long and used glue lined heat shrink to attach it to the end of one wire. Then measure carefully to get 12" spacing, and heat shrink the other end. There's no real tension on the wires so this should be plenty strong.

Based on this diagram, my 72" driveway markers should let me get up to 12m. We'll see. 6m was surprisingly short, so I'm optimistic.

Parker Duofold

NES Member

Early this week, I replaced the 4:1 balun on my OCF inverted vee. Everything is working again and the old balun is DEAD.

ToddDubya

NES Member

What happened to it? Is it salvageable?Early this week, I replaced the 4:1 balun on my OCF inverted vee. Everything is working again and the old balun is DEAD.

Parker Duofold

NES Member

It's difficult to determine what happened but it's definitely "cooked." It's one of those units that is built into a piece of PVC tubing and end caps. I don't know how you can get it apart. Is there a solvent that will soften the PVC glue? If so I'll take it apart. Trying to get the SWR down on, say, 80 meters with a somewhat high SWR while using a matchbox creates a LOT of voltage at the feedpoint. Try to use the antenna on 160 meters even though it's designed for 80-10 really creates a lot of voltage at the feedpoint. I should be more careful.What happened to it? Is it salvageable?

I'd like to build a HEX beam for 40 - 10 meters.

ToddDubya

NES Member

Could you just cut it open? I don't' think you can unbond PVC; I think it's somewhat of a welding process, but I'm no plumber. If the core is still good you could rewind it and have a spare.

A 40m hex would be huge. The ones I've seen typically top out at 20m. I think the first good gust of wind and you'd lose anything bigger.

Damn it's cold out. I wanted to work on my 10m hex but it's really cold and windy.

A 40m hex would be huge. The ones I've seen typically top out at 20m. I think the first good gust of wind and you'd lose anything bigger.

Damn it's cold out. I wanted to work on my 10m hex but it's really cold and windy.

ffej ruedorb

NES Member

- Joined

- Oct 23, 2016

- Messages

- 354

- Likes

- 1,096

thought about and did some research on a mic upgrade for the shack. I am thinking boom mic, probably a budget boom mic setup with adapters made instead of bought.

I have a 6 Channel mixer for audio from radios, computer etc and it has Bluetooth. That mixer feeds a stereo amplifier to 2 bhi speakers. I think there is a way to wire a mic into the mixer then to radios. I also think i should get get a separate mixer for mic feed to radios. 1 mic 2 speakers for 2 radios ic7610 and 2m to 70m not yet purchased

Much more research to do

I have a 6 Channel mixer for audio from radios, computer etc and it has Bluetooth. That mixer feeds a stereo amplifier to 2 bhi speakers. I think there is a way to wire a mic into the mixer then to radios. I also think i should get get a separate mixer for mic feed to radios. 1 mic 2 speakers for 2 radios ic7610 and 2m to 70m not yet purchased

Much more research to do

Last edited:

I was going to say "hacksaw".Could you just cut it open?

n1oty

NES Member

I've been having a lot of fun lately in my mobile shack-on-wheels ever since I installed my Scorpion Antenna. Man, this thing is way better than the ATAS-120a antenna. I was working SSB into Europe on 15 and 17 meters all morning. I also recently used it for a couple of POTA ops that I did in Ohio a couple of weeks back.

ToddDubya

NES Member

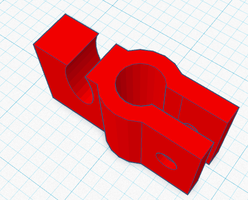

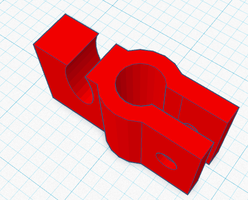

It's not the prettiest thing but I drew this up last night and made a test print this afternoon. This is to hook the hexbeam wire. I didn't want to feed the wire through holes, so I made a gap, which looks like it should work. A screw/nut hold it pretty tight. The wire isn't under any real tension so it should hold just fine. Worst case I can add a wrap of tape around the rod to thicken it up. I might do that anyway once I establish where they should all go in case they do move I'll know where to put them back.

I made a couple tweaks where things didn't line up quite right, and I'm gonna print up a set of six.

This morning it did occur to me I could just tape paperclips on![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif) .

.

Having never really messed with CAD before, I was surprised how many parts it took to add/subtract together in the right order to make that shape.

I made a couple tweaks where things didn't line up quite right, and I'm gonna print up a set of six.

This morning it did occur to me I could just tape paperclips on

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif) .

.

Having never really messed with CAD before, I was surprised how many parts it took to add/subtract together in the right order to make that shape.

Parker Duofold

NES Member

Yes. I meant to say 20 - 10.A 40m hex would be huge. The ones I've seen typically top out at 20m. I think the first good gust of wind and you'd lose anything bigger.

ToddDubya

NES Member

I almost impulse bought the Buddihex one with one of their awesome but exf***ingspensive rotatable tripod masts this summer. If I had a real use for it I probably still would. But it's like $1400 all said and done, and it's probably not intended to be permanent.Yes. I meant to say 20 - 10.

Share: