38ExtraSpecial

NES Member

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

![Angry [angry] [angry]](/xen/styles/default/xenforo/smilies.vb/008.gif) They were in a lot of once fired Win cases I bought recently. I was too cheap to scrap them so I removed the crimp.

They were in a lot of once fired Win cases I bought recently. I was too cheap to scrap them so I removed the crimp.I loaded the last of my 9mm bullets on Sunday. Got another 3k bullets arriving tomorrow. At 150+ grains each, the mailman is going to love me lol.

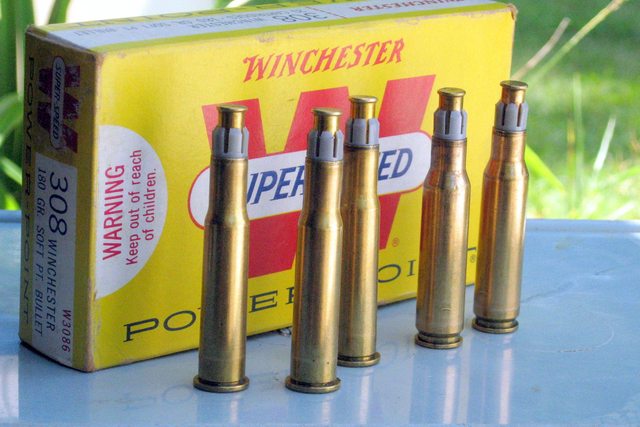

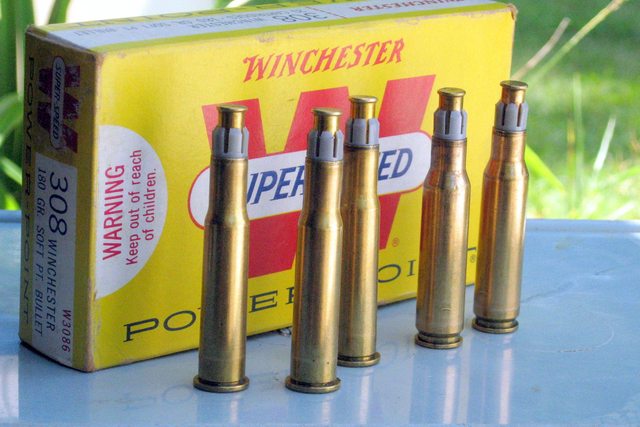

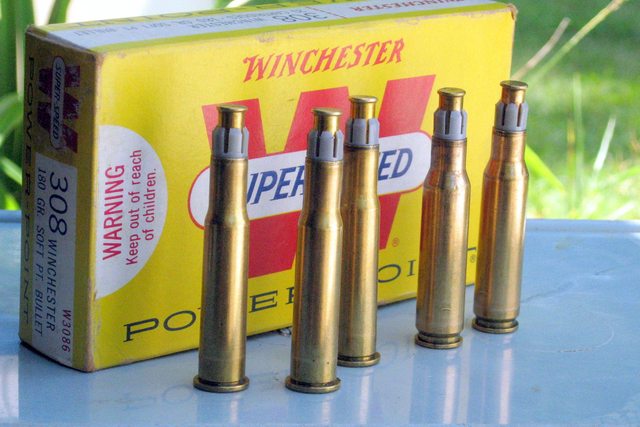

Also ran into a bunch of Winchester 9mm cases with crimped primer pocketsThey were in a lot of once fired Win cases I bought recently. I was too cheap to scrap them so I removed the crimp.

Just sorted about 2 gallons of brass.

Batch of 38 tumbling as we speak. Next will be 45.

I did find a turned 38 special case in the mix. Kind of cool. I wonder if there are any others I missed. I only noticed this one because the mouth was split and a little crushed.

I'll have to show some pics.

Military brass?

Could be. It's identical to all other Win brass except for the crimp.

And is that 'turned' like 'machined?'

I shot the 10mm loads this morning. It was the first time I shot a 10mm and here are my thoughts. It's much faster than the .45acp. Even the light loads pushed a 180 grain bullet at over 1100 fps. Recoil from a 10mm is supposed to be bad but I didn't find it any worse than the .45acp. It was quite accurate. I have lots of load development to do but it looks promising.

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)

Started adapting an extra multitube case feeder to work on the bullet feeder. This adaptation is different then how the Lee Multitube Bullet Feeder mounts since I wanted to have about 6-8 bullets still in the feeder and still be able to change tubes. This will prevent the bullet spilling that occurs when the feeder gets too low. Used polyethylene tubing that is semi-flexible, but I managed to get most of the bend out of it by filling with bullets, taping the ends and running it in hot water. Initially tried setting it in the oven at 200, but that didn't work out well (good thing I had enough extra tubing). The tubing that I used as a junction between the multitube and the feeder works, but I will instead use a short piece of iron pipe.

Yes, I know that I could have just bought the multitube feeder for about $15.00, but that isn't the point. I just wanted to make one my way.![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)

Started adapting an extra multitube case feeder to work on the bullet feeder. This adaptation is different then how the Lee Multitube Bullet Feeder mounts since I wanted to have about 6-8 bullets still in the feeder and still be able to change tubes. This will prevent the bullet spilling that occurs when the feeder gets too low. Used polyethylene tubing that is semi-flexible, but I managed to get most of the bend out of it by filling with bullets, taping the ends and running it in hot water. Initially tried setting it in the oven at 200, but that didn't work out well (good thing I had enough extra tubing). The tubing that I used as a junction between the multitube and the feeder works, but I will instead use a short piece of iron pipe.

Yes, I know that I could have just bought the multitube feeder for about $15.00, but that isn't the point. I just wanted to make one my way.![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)

Since I don't have a Rock Chucker Bullet Swager set, I figured I'd find another use for the empty .22LRs - essentially they make a 6.5mm+ projectile as measured from the rim. Now to find someone that shoots the .30-30...

Total projectile weight: ~ 75 grains.

Devastating on water jugs. So far they are stable out to 100 meters and they really make crisp holes in paper, if that's your objective.

Since I don't have a Rock Chucker Bullet Swager set, I figured I'd find another use for the empty .22LRs - essentially they make a 6.5mm+ projectile as measured from the rim. Now to find someone that shoots the .30-30...

Total projectile weight: ~ 75 grains.

Devastating on water jugs. So far they are stable out to 100 meters and they really make crisp holes in paper, if that's your objective.

Has anyone loaded for 6.5 Grendel or Creedmoor? I'm looking for powder suggestions to work up loads.

Grendel is a hunting load behind a Barnes 120 gr TTSX

Creedmoor is 1,000 yards behind a 147 gr ELD-M.

Anyone load 30-40 Krag? I found 16 once fired Graf's 30-40 Krag cases at the range and snatched them quickly so they wouldn't get scrapped. Figured someone might be able to use them.