Picked up some old Speer 160 grain jacketed soft point 38s from one of the local shops clearing out an estate. I think they need to go through an Airweight and find some steel.

View attachment 691555

3.9g Titegroup, CCI 500, Speer 160g JSP

Out of the 442, 1 7/8" barrel:

1 2 3 4 5 - Avg SD ES

656 676 756 736 693 - 703 42 100

586, 6" barrel:

693 693 711 709 723 - 706 13 30

Walked over to the 100 yard rifle range. Making hits on a torso silhouette with the 586 was pretty easy. With the snub, much harder, but out of 5 I was able to put 2 on it, with my hands resting on the bench. I thought I was going to have to hold over, but I was sending them over the top when I did that. Sights were dead on at 100 yards.

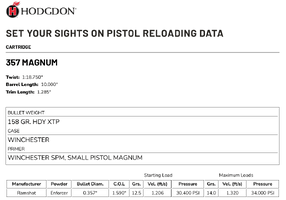

Also chronoed these 357s. The first one is loud, with a lot of recoil, and it really rings the steels. Second pretty similar but toned down a little. Third noticably less concussion and recoil but still obviously a magnum.

13.4g 2400, CCI 500, Sierra #8350 170g FMJ

1267 1218 1259 1227 1184 - 1231 33 83

14.4g 2400, CCI 500, Zero 158g JSP

1236 1216 1242 1224 1204 - 1224 15 38

17.0g 2400, CCI 500, Speer #4013 125g JHP

1400 1364 1380 1353 1333 - 1366 26 67

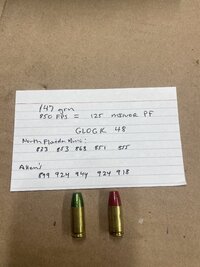

Aaaand... because I have plenty of components and these turned out pretty good... 40 S&W out of a G22. Also easy to make 100 yard hits on a full size torso silhouette. These are full power, but don't slap the slide against the frame too sharply.

6.5g Power Pistol, Fed 100, Zero 180g FMJ flat nose

993 1003 985 989 998

975 988 986 989 994 - 994 7.1 18