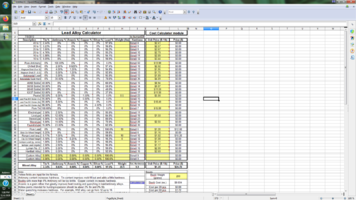

Alloy spreadsheet:

I have it working on my laptop (iPhone doesn’t seem to want to let me edit fields).

my objective is to estimate how much “stuff” (wheel weights, pewter coins, range scrap etc) I should mix in w the pure lead I just got from a roofer. Goal is 9mm flat round nose and 9mm hollow points (all just for target practice). I started by putting in 10lb of lead and 1lb of pewter. It computed a Brinell of 11.5. Which brings me to my question... what hardness am I aiming at achieving to allow easy coating, sizing and chootin?

View attachment 408519

Separate issue:

You wanted me to mark the bullets and run them through the sizer. Problem is that I already ran the whole bag of 500 through the sizer. So I’ll have to cast and coat some new ones before I can get you an answer to the sizing die question.

If you need to make a alloy you can run something like this. It will give you 2% Tin

Another variable we dont know is your roof flashing. It could be pure or have a good amount of Atimony in it.

I had a batch of roof flashing tested and it came back with +3% antimony I have it right on 12 BHN with the pencil test.