not sure why i'm responding to this

are you a glock armorer? nope.

it is lubricated with mil com tw-25b

who the F has visible "drops of oil" after disassembly a carried pistol

some fuddy shit right there

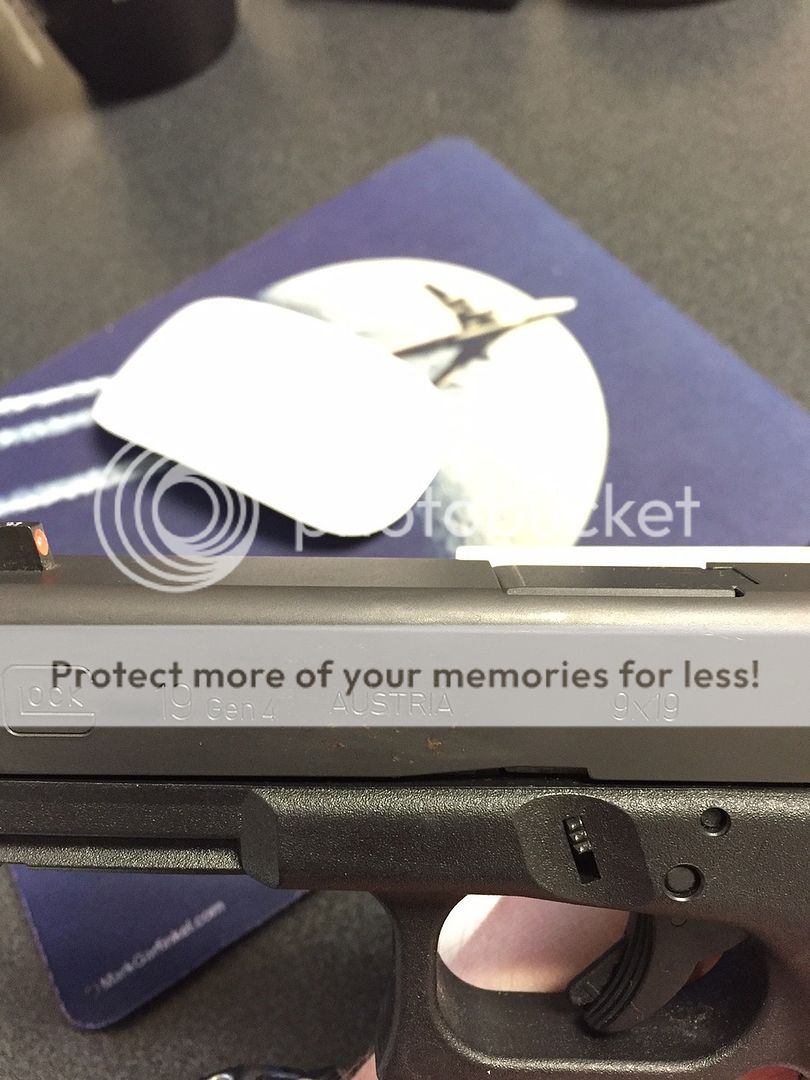

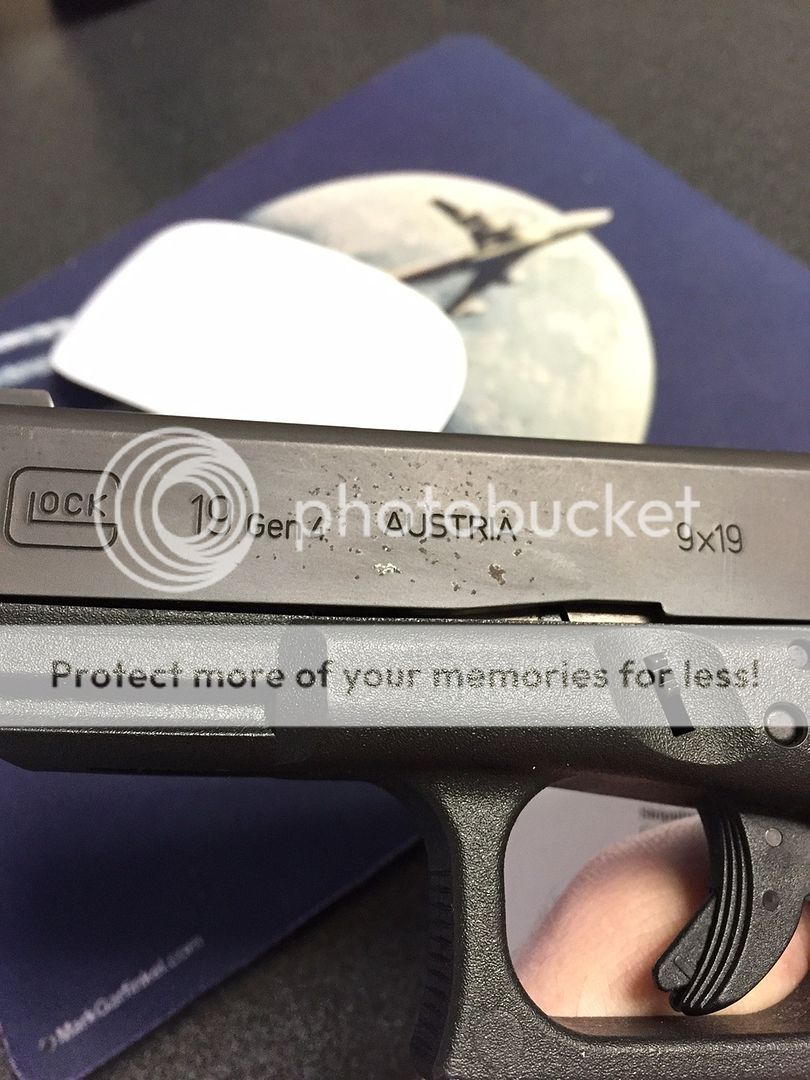

there is no neglect

it is a heavily carried and used firearm

there is an issue with the finish on some gen 4's

well established

--

@Broccoli Iglesias

how can you say it wasn't 1 month? can I not count?

it was disassembled approx 1 month ago after range trip including the striker

re-assembled and put in holster

i have been sweating on it like a freak, jogging daily in 90F+ with huge amounts of my disgusting peri-menopausal sweat

wasn't really thinking about it until a month later

consider it a sweat test

apparently some gen 4's fail it

i suspect my other glocks would do fine

--

for those of you having a seizure right now, i'm not saying corrosion like this is normal. it ain't. but i also think my sweating all over the gun hastened it. i plan on updating the thread over time so it will be a fun rust experiment for all of us.

![ROFL [rofl] [rofl]](/xen/styles/default/xenforo/smilies.vb/013.gif) Glock upper internals are supposed to be bone dry and clean.

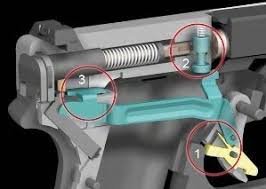

Glock upper internals are supposed to be bone dry and clean.

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)

![Kiss [kiss] [kiss]](/xen/styles/default/xenforo/smilies.vb/022.gif)