-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

-

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Glock Perfection; dba "That will buff right out"

- Thread starter allen-1

- Start date

On somewhat of a related tangent, in this day and age, why are pistols so expensive? It can’t cost Glock more than $10 to injection mold the handle, all the barrels and slides etc are all CNC or at the very least automated from a couple dollars of steel, only hand work I could imagine there being is assembly which isn’t even that expensive considering how quickly an experienced person can disassemble and assemble a pistol completely.

EddieZoom

NES Member

It'd work out just fine "in MA" depending on how smart the person with the broken gun is.

-Mike

I don't know....something tells me this story wouldn't have a happy ending in the people's republic.

Mesatchornug

NES Member

You might want to learn a bit more about mass production...turns out there's a lot more to pricing than COGS. Also, metal costs more than you think...On somewhat of a related tangent, in this day and age, why are pistols so expensive? It can’t cost Glock more than $10 to injection mold the handle, all the barrels and slides etc are all CNC or at the very least automated from a couple dollars of steel, only hand work I could imagine there being is assembly which isn’t even that expensive considering how quickly an experienced person can disassemble and assemble a pistol completely.

Only if someone is incapable of thinking outside the box.I don't know....something tells me this story wouldn't have a happy ending in the people's republic.

You are right, you could make a killing selling $50 guns.On somewhat of a related tangent, in this day and age, why are pistols so expensive? It can’t cost Glock more than $10 to injection mold the handle, all the barrels and slides etc are all CNC or at the very least automated from a couple dollars of steel, only hand work I could imagine there being is assembly which isn’t even that expensive considering how quickly an experienced person can disassemble and assemble a pistol completely.

Snap your fingers and a factory with all the equipment, employees, raw materials and patented gun designs will appear out of nowhere. The best part is, none of that will have labor costs, taxes or maintenance costs.

If you snap your fingers a second time, all your sales, shipping and marketing costs disappear.

And if you snap them a third time, all your insurance and legal costs also disappear.

It is as easy as 1, 2, 3.

Just so I’m clear, you think it costs Glock the same to injection mold a plastic frame, stamp out some metal pieces, and do a bit of CNC work as it does for Apple to source lithium, turn that into batteries, generates silicone, turn it into hundreds of chips, transitions, make a glass and metal frame, assemble, write code, etc. etc.You are right, you could make a killing selling $50 guns.

Snap your fingers and a factory with all the equipment, employees, raw materials and patented gun designs will appear out of nowhere. The best part is, none of that will have labor costs, taxes or maintenance costs.

If you snap your fingers a second time, all your sales, shipping and marketing costs disappear.

And if you snap them a third time, all your insurance and legal costs also disappear.

It is as easy as 1, 2, 3.

No, I don’t know what goes into a manufacturing plant, but I do know there’a about 1000x more that goes into producing a $600 laptop than a $600 Glock which makes me highly suspicious of the actual manufacturer costs, which was my point.

pastera

NES Member

Economy of scale explains the difference.Just so I’m clear, you think it costs Glock the same to injection mold a plastic frame, stamp out some metal pieces, and do a bit of CNC work as it does for Apple to source lithium, turn that into batteries, generates silicone, turn it into hundreds of chips, transitions, make a glass and metal frame, assemble, write code, etc. etc.

No, I don’t know what goes into a manufacturing plant, but I do know there’a about 1000x more that goes into producing a $600 laptop than a $600 Glock which makes me highly suspicious of the actual manufacturer costs, which was my point.

The majority of parts in that laptop are used in countless other devices so the NRE for each part is negligible when spread across the tens of millions of parts sold.

The majority of parts in a gun are unique to that gun so the NRE is only spread across a relatively small number of products.

It takes a lot of parts to spread the cost of a $70-100k mold and even more to pay the engineer to design it in the first place.

All those stamped parts - the dies to cut and fold those parts are complex and costly

I think you dont know a lot of things, and now you are trying to compare a gun to a computer.Just so I’m clear, you think it costs Glock the same to injection mold a plastic frame, stamp out some metal pieces, and do a bit of CNC work as it does for Apple to source lithium, turn that into batteries, generates silicone, turn it into hundreds of chips, transitions, make a glass and metal frame, assemble, write code, etc. etc.

No, I don’t know what goes into a manufacturing plant, but I do know there’a about 1000x more that goes into producing a $600 laptop than a $600 Glock which makes me highly suspicious of the actual manufacturer costs, which was my point.

Unless the Mass LTC holder lies and claims the gun was stolen, he's gonna get hit with a storage violation.It'd work out just fine "in MA" depending on how smart the person with the broken gun is.

-Mike

I think we have our wires crossed here I was referring to the idea of getting the gun repaired by glock, not the part about the gun falling off of the motorcycle...Unless the Mass LTC holder lies and claims the gun was stolen, he's gonna get hit with a storage violation.

Ahhh.I think we have our wires crossed here I was referring to the idea of getting the gun repaired by glock, not the part about the gun falling off of the motorcycle...

Just so I’m clear, you think it costs Glock the same to injection mold a plastic frame, stamp out some metal pieces, and do a bit of CNC work as it does for Apple to source lithium, turn that into batteries, generates silicone, turn it into hundreds of chips, transitions, make a glass and metal frame, assemble, write code, etc. etc.

No, I don’t know what goes into a manufacturing plant, but I do know there’a about 1000x more that goes into producing a $600 laptop than a $600 Glock which makes me highly suspicious of the actual manufacturer costs, which was my point.

Lol, not sure if serious dude, people gotta eat. Nobody makes guns as a social charity or something. You have to make enough profit to justify existing, pay a shitload of employees, sales, marketing, warranty/service/parts fulfillment (which for Glock and a bunch of other companies covers the guns for decades) You also have to make enough profit to carry the company over when every so many years the market gets stagnant and you have slower sales.

Most of Glocks peers aren't giving their guns away, why should they? Free market at work. It's literally that simple, outside of the federal excise tax on firearms. (which makes eveyrthing like 8% more expensive than its supposed to be, but thats all out of the manufacturers control).

Let's look at the other side of the industry shall we? A Hi Point is basically made out of compressed liquid feces with a barrel in the middle of it, and even those pieces of dog

meat cost like $150-200 bucks new. Basically its a gun made the cheapest way possible, with the cheapest packaging, most flinting, least warranty fulfillment requirements, etc.

600 dollar laptops???? dude, just stop digging. That's a trip. (at new price) by the way are pieces of dog shit that you'll be lucky to get 5 years out of most of them, on the other hand a decent pistol like a Glock or something similar will probably last longer than any of us will. The value prop of most consumer grade laptops (or things like cell phones, to use a more common example) is extremely poor. On the other hand you take a Glock, XD, CZ P10, etc.... at 500-700 bucks (dep on model and config) that situation is basically inverted. There is no comparison, consumer grade electronics are pumped out by the metric ton and the market compresses itself. Plus in consumer electronic land the 600 dollar piece of shit blows up in 2-5 years and people buy another one to replace it. With guns some people might buy only 2 guns their entire life and market has sort of a saturation point.

The fact that Glocks, XD, etc, still only cost what they do is actually pretty amazing given the inflation that's hit other handguns. in the past 10-15 years I've seen other handguns go up by like $50-100 bucks or more mostly due to inflation or raw material, import costs. Like the days of the $400 CZ-75B are long gone.

The same is true for electronics. Batteries and boards are often cut exactly for that model, chips are programmed specifically for certain tasks, to run with certain components, displays meant for just that model, and certainly code is written by highly paid individuals for an extremely specific application. There are a number of components that are widely used (like resistors which are fairly universal in many applications, etc) but those have to be manufactured by someone else and many of these companies are paying a premium for the manufacturing costs of those.The majority of parts in a gun are unique to that gun so the NRE is only spread across a relatively small number of products.

We can extend this example to any number of non-electronic devices but the point remains the same. Porsche sells a single headlight assembly for $2k, which is essentially a bit of plastic and a lens, or I can buy a SureFire for $200 thats brighter and comes with all the power regulation bits, etc. Does it really cost Porsche 10x more to make their plastic, or is there some premium because they can?

There are any number of examples that don't involve electronics, but my point still stands, and was more a commentary on production vs retail costs in general. You going to tell me it takes BMW an extra $15k to give you an engine 1 liter larger, especially when it uses the same transmission, connecting rods, etc? I can buy a $1900 Shirogorov knife (<10 parts in total) or 2 P320 Legions. I can get a Glock or a Nikon dSLR camera, with shutter assemblies, etc. I'm not saying I won't (and don't) happily shell out the money for all of this but, when I stand back and look at it, I find it difficult to find the justification in costs sometimes.Lol, not sure if serious dude, people gotta eat. Nobody makes guns as a social charity or something. You have to make enough profit to justify existing, pay a shitload of employees, sales, marketing, warranty/service/parts fulfillment (which for Glock and a bunch of other companies covers the guns for decades) You also have to make enough profit to carry the company over when every so many years the market gets stagnant and you have slower sales.

Most of Glocks peers aren't giving their guns away, why should they?

Let's look at the other side of the industry shall we? A Hi Point is basically made out of compressed liquid feces with a barrel in the middle of it, and even those pieces of dog

meat cost like $150-200 bucks new. Basically its a gun made the cheapest way possible, with the cheapest packaging, most flinting, least warranty fulfillment requirements, etc.

600 dollar laptops???? dude, just stop digging. That's a trip. (at new price) by the way are pieces of dog shit that you'll be lucky to get 5 years out of most of them, on the other hand a decent pistol like a Glock or something similar will probably last longer than any of us will. The value prop of most consumer grade laptops (or things like cell phones, to use a more common example) is extremely poor. On the other hand you take a Glock, XD, CZ P10, etc.... at 500-700 bucks (dep on model and config) that situation is basically inverted. There is no comparison, consumer grade electronics are pumped out by the metric ton and the market compresses itself. Plus in consumer electronic land the 600 dollar piece of shit blows up in 2-5 years and people buy another one to replace it. With guns some people might buy only 2 guns their entire life and market has sort of a saturation point.

The fact that Glocks, XD, etc, still only cost what they do is actually pretty amazing given the inflation that's hit other handguns. in the past 10-15 years I've seen other handguns go up by like $50-100 bucks or more mostly due to inflation or raw material, import costs. Like the days of the $400 CZ-75B are long gone.

If the reason is as you say, that they have to charge more because of market saturation, than thats fine, and I can understand and get behind that. But I still stand by what I said that it really can't cost all that much to pump out a plastic frame and a dozen or so stamped metal pieces, especially when you compare it to products much more involved and with just as many mouths to feed and lights to keep on, etc.

Soundwave

NES Member

That extra mark up is what allows them to have such awesome warranty/customer service. I sent my gen 2 back to them and they checked it over and refurbished/replaced all the internals etc for free. It only cost me like $60 to have the slide and barrel refinished while it was there. The only problem is the refinish looks blotchy because the old tenifer was that good. I should have skipped that

So again, my original point, how much can it really cost them to produce in the first place? It sounds like so far the answer to my question of "why are they so expensive" is market saturation and customer service.That extra mark up is what allows them to have such awesome warranty/customer service. I sent my gen 2 back to them and they checked it over and refurbished/replaced all the internals etc for free. It only cost me like $60 to have the slide and barrel refinished while it was there. The only problem is the refinish looks blotchy because the old tenifer was that good. I should have skipped that

There are any number of examples that don't involve electronics, but my point still stands, and was more a commentary on production vs retail costs in general. You going to tell me it takes BMW an extra $15k to give you an engine 1 liter larger, especially when it uses the same transmission, connecting rods, etc? I can buy a $1900 Shirogorov knife (<10 parts in total) or 2 P320 Legions. I can get a Glock or a Nikon dSLR camera, with shutter assemblies, etc. I'm not saying I won't (and don't) happily shell out the money for all of this but, when I stand back and look at it, I find it difficult to find the justification in costs sometimes.

Different product, different market, different rules. Different economy of scale, even. Some company like HP produces more shitty consumer laptops in a quarter than glock does guns in an entire year, more than likely. The subsystems in those machines are probably produced in 2 or 3 factories that make laptops for pretty much everyone.

And yes, sometimes stuff does cost more "because it can" like in your BMW example. So what? who gives a shit? don't buy it.

![ROFL [rofl] [rofl]](/xen/styles/default/xenforo/smilies.vb/013.gif)

I smoke handrolled cigars. In that industry a lot of products "subsidize the others" thats pretty much normal practice in a lot of things. As a fun example basically all the people who smoke smaller handrolled cigars, custom shapes like figurados, and torpedos, etc.... all those guys are paying a disproportionate cost in the same product line. But they don't care, because they want the weird cigar enough to pay an extra 50 cents or a buck for it, even if they're getting 10-20% less tobacco. So in a given product line these guys subsidize the price reduction of other more

common cigar sizes. Guess what, everyone (well, at least anyone that looks at the prices/products in the same line and compares them) knows this, and nobody cares.

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif)

For market segments that are less sensitive, the price will be disproportionately higher. BMW can get away with "that" as an example because the guys buying the extra liter are less price sensitive than the peons buying the leasetard special with the small motor in it.

The thing you're complaining about, is just a reality of the free market.

As a certain famous character in the gun industry would say...

"I'm Larry potterfield...."

pastera

NES Member

BOM cost is a very small part of product pricing and marketingSo again, my original point, how much can it really cost them to produce in the first place? It sounds like so far the answer to my question of "why are they so expensive" is market saturation and customer service.

Why do Porsche headlights cost so much? because relatively few are produced and those who want them are willing and able to pay to enter a more exclusive market.

Why not invent a Glock killer that you can market for $250? Go ahead the profit is there, right?

The same is true for electronics. Batteries and boards are often cut exactly for that model, chips are programmed specifically for certain tasks, to run with certain components, displays meant for just that model, and certainly code is written by highly paid individuals for an extremely specific application. There are a number of components that are widely used (like resistors which are fairly universal in many applications, etc) but those have to be manufactured by someone else and many of these companies are paying a premium for the manufacturing costs of those.

We can extend this example to any number of non-electronic devices but the point remains the same. Porsche sells a single headlight assembly for $2k, which is essentially a bit of plastic and a lens, or I can buy a SureFire for $200 thats brighter and comes with all the power regulation bits, etc. Does it really cost Porsche 10x more to make their plastic, or is there some premium because they can?

No, batteries are often OEM'd and part marked for a specific model. They are quite alike except for a commodity level connector and labeling

The unique batteries fall into two categories

- High performance - these batteries go into the high end units with markups over BOM greater than you see in the gun industry (think brand new iPhone)

- Bargain basement - these batteries are specifically designed to meet an absolute low price using known, proven technologies where NRE has already been recovered (in type 1 products)

Programmed parts? very few mask programmed parts are made today except where millions are expected to be produced (further proving my point)

Most code makes use of standard libraries so again there is the economy of scale operating.

I work in the defense industry in a very small niche - when lifetime production is less than 100 of an item things get ridiculously expensive not because of the BOM but simply because of all of the design, manufacturing and support effort needed.

And that's fair, but doing a quick search (aka unverified info), it seems Glock's output is ~80k units per WEEK. So yes, premiums for the Porsche headlights and chipsets going into your missile are justified by limited production, but it would seem Glock's are a full fledge "mass-produced" item with numbers like that.I work in the defense industry in a very small niche - when lifetime production is less than 100 of an item things get ridiculously expensive not because of the BOM but simply because of all of the design, manufacturing and support effort needed.

It was honestly a genuine question and not an attack. I'm was curious what the justification for the price was. I could see there being something I wasn't aware of, like maybe some kind of weird import or firearms manufacturing tax, some complex polishing step for the action, etc. But from an outsider looking in, it's difficult to see how you can buy a polymer frame pistol or an O/U shotgun with wood, metal engraving, tons of steel on the barrel, double the action work, etc, for not much difference in price.

Soundwave

NES Member

Comparing an O/U shotgun to a pistol with more moving parts etc seems odd. But again it you're going to support your product for a true lifetime with really no questions asked how could you ever stay in business without extra markup on the original product? I'm trying to shop for a holster for my dad. One company(ANR maybe?) wants $15 for a lifetime warranty otherwise you only get 30 days!?! This is on a holster that costs under or around $100. How much could it possibly cost to produce a kydex holster??

pastera

NES Member

I would suspect legal compliance costs are large on firearms but for Glocks I suspect a lot of it is the market - people are willing to pay more for a known quality product with great supportAnd that's fair, but doing a quick search (aka unverified info), it seems Glock's output is ~80k units per WEEK. So yes, premiums for the Porsche headlights and chipsets going into your missile are justified by limited production, but it would seem Glock's are a full fledge "mass-produced" item with numbers like that.

It was honestly a genuine question and not an attack. I'm was curious what the justification for the price was. I could see there being something I wasn't aware of, like maybe some kind of weird import or firearms manufacturing tax, some complex polishing step for the action, etc. But from an outsider looking in, it's difficult to see how you can buy a polymer frame pistol or an O/U shotgun with wood, metal engraving, tons of steel on the barrel, double the action work, etc, for not much difference in price.

There is also the distribution system that sucks up lots of profit - if firearms were sold direct to consumer or even direct to retail, you would see large price drops.

I'm also not aware of a O/U with engraving and wood furniture with the same quality control and support of Glock at the same price point.

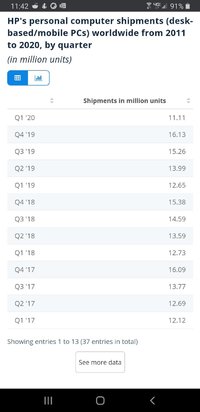

Different product, different market, different rules. Different economy of scale, even. Some company like HP produces more shitty consumer laptops in a quarter than glock does guns in an entire year, more than likely.

HP produces more in a quarter than Glock and Ruger combined produce handguns in a decade. I would place a bet on that.

The handguns will be around in 100 years and they will still work. The HP product will be slow AF in 3 years and in the dumpster by year 4-5.

And $600 laptops are a major POS with cheap and often old CPU.

Dont feed the troll.

Edit:

I had to go find it...

HP Inc. PC unit shipments by quarter 2022 | Statista

In the fourth quarter of 2022, PC shipments from HP amounted to 13.22 million units worldwide, placing the company in second place behind Lenovo in the rankings.

Last edited:

So again, my original point, how much can it really cost them to produce in the first place? It sounds like so far the answer to my question of "why are they so expensive" is market saturation and customer service.

Re-read what I wrote when I told you to snap your fingers 3 times.

Everyone that touches the gun adds to the cost of production. A guy making $20/hr and touching the gun for 10 minutes adds $3.33 (in reality it is more because there are other employment costs not reflected on the salary you see, so in reality it is probably around $5-6 for those 10min) to the cost of the gun. Even if Glock purchases in bulk, those materials have a cost and it is not $2/gun.

On top of the people touching the gun, you have a ton of people thar DONT touch the gun, but the costs need to be factored in ... the dude stacking boxes in the warehouse, the guys driving those boxes from point A to B, the people in the office working on Marketing, Operstions, HR, Sales, Support, Secretaries, all the office supplies needed to do the job, the cost of paying a company to clean the office, security guards for the warehouse and factory, the people managing the guy touching the gun for 10 minutes, the people managing those that are managing ...

When all those costs are accounted for, you need to start thinking about taxes and when that is done, you need to think about government mandated taxes on your goods.

Additionally you have a group of engineers, these guys not only work on improving your guns and testing them (usually a separate group testing with the engineers), but these guys work on future designs, things that haven't made any money yet, things that a market research group (also another cost) told them to bet on.

When all that is done you need lawyers. Lawyers to defend the company and lawyers to parents your designs and occasionally go after another company when they copy your design.

Finally, the price you pay for the gun has a markup, you know, that retailer that didnt produce it also has to make money.

That gun you paid $500 for, was probably produced for $150 - $200, sold to a distributor for $300-350 who sells it to a retailer for $400, who sells it to you for $500.

Factories include rebates for volume, so that could eat another $10-20/gun for the factory, but they do it to reward volume.

I almost forgot ... all the people working on warranty repairs. Those people are not touching a new gun if they are busy fixing one that was run over by a truck.

As you can see, thinking a gun is just a dude touching it for two seconds + $2 of metal + a few bucks of plastics shows you are ignorant AF.

Show me any other product that has to go through the abuse a gun goes through every time you pull the trigger and will still be around and working 100 years from now and it only costs $500-1500.

As proof, we are still shooting WW1 guns that saw action, and those are over 100 years old. We are shooting WW2 guns, and those are very close to 100 years old.

Are you still using the laptop you purchased in 2009? ... most likely not.

Last edited:

allen-1

NES Member

The lower, (aka frame), should be arriving Monday.

The Talon Wrap, Warren Tactical front sight and GlockTriggers trigger all arrived last week.

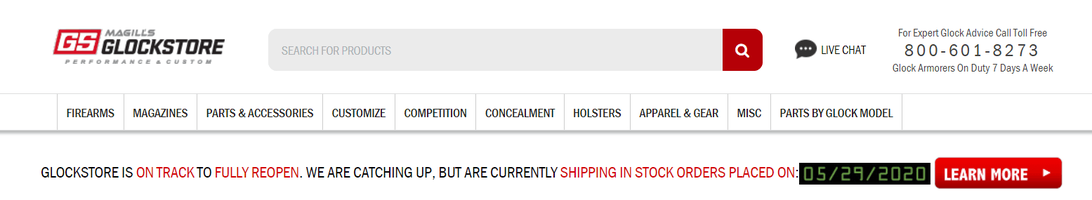

I need the rear slide cover plate - and I ordered it along with a mag from GlockStore on 06/10.

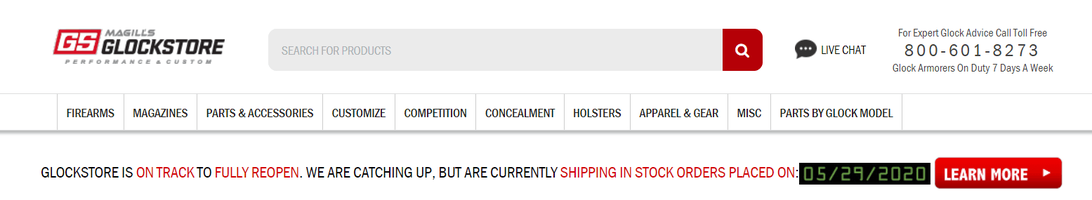

Checked on it just now and saw:

So, today's the 19th of June. I ordered it 9 days ago, and they're processing orders from 20 days ago. Which means that they won't process my order for at least another week.

I think I'm gonna go shopping elsewhere because that's the last piece I need once I have the frame to put this gun back together.

The Talon Wrap, Warren Tactical front sight and GlockTriggers trigger all arrived last week.

I need the rear slide cover plate - and I ordered it along with a mag from GlockStore on 06/10.

Checked on it just now and saw:

So, today's the 19th of June. I ordered it 9 days ago, and they're processing orders from 20 days ago. Which means that they won't process my order for at least another week.

I think I'm gonna go shopping elsewhere because that's the last piece I need once I have the frame to put this gun back together.

Mesatchornug

NES Member

At this point, a lot of this is starting to overlap this thread:And that's fair, but doing a quick search (aka unverified info), it seems Glock's output is ~80k units per WEEK. So yes, premiums for the Porsche headlights and chipsets going into your missile are justified by limited production, but it would seem Glock's are a full fledge "mass-produced" item with numbers like that.

It was honestly a genuine question and not an attack. I'm was curious what the justification for the price was. I could see there being something I wasn't aware of, like maybe some kind of weird import or firearms manufacturing tax, some complex polishing step for the action, etc. But from an outsider looking in, it's difficult to see how you can buy a polymer frame pistol or an O/U shotgun with wood, metal engraving, tons of steel on the barrel, double the action work, etc, for not much difference in price.

Would you buy a PSA Glock clone for $300? Introducing the PSA Dagger.

No actually, I probably will not. https://www.ballisticmag.com/2020/05/18/palmetto-state-ps9-dagger-glock-clone/

In order to not give still more to read, here are a couple videos that give a little of the idea of what's going on in all this:

Here's what's been going on with the updated KE Arms lower for the WWSD2020 project:

View: https://www.youtube.com/watch?v=QmhYMRNzFu8

Here are some of the speed bumps that delayed the release of PSA's $300 Gen3 Glock19 clone:

View: https://www.youtube.com/watch?v=xHHYkSxHweU

None of these directly answer "why do they charge so much?" but hopefully they give an idea of the extra steps, like surface finishes, coating applications, etc. that add cost to a product.

Mesatchornug

NES Member

Looking at the background of the guy giving the talks and the amount of talking he's doing, I believe it'll be out by the end of summer. I don't believe it'll be magic. And I don't believe it'll be in stock most of the time.

But here in MA, what's it matter, right?

But here in MA, what's it matter, right?

allen-1

NES Member

I mailed my trashed lower to Glock on June 8th, that's Monday of last week.

Today, Saturday the 20th, Fedex delivered the replacement frame.

Note that the frame is complete, IE it has all of its internals; all it needs is a slide.

@Rob Boudrie said earlier "If the serial number starts with a single character (G), it's a frame made to be a replacement. If it starts with more than one letter, it's scavenged off of a once complete gun. "

The serial number of this frame does indeed start with "G" followed by numerics.

Today, Saturday the 20th, Fedex delivered the replacement frame.

Note that the frame is complete, IE it has all of its internals; all it needs is a slide.

@Rob Boudrie said earlier "If the serial number starts with a single character (G), it's a frame made to be a replacement. If it starts with more than one letter, it's scavenged off of a once complete gun. "

The serial number of this frame does indeed start with "G" followed by numerics.

TZCHRIS

NES Member

Can you try number 4 and make Marsha disappear.....You are right, you could make a killing selling $50 guns.

Snap your fingers and a factory with all the equipment, employees, raw materials and patented gun designs will appear out of nowhere. The best part is, none of that will have labor costs, taxes or maintenance costs.

If you snap your fingers a second time, all your sales, shipping and marketing costs disappear.

And if you snap them a third time, all your insurance and legal costs also disappear.

It is as easy as 1, 2, 3.

Share:

Similar threads

- Replies

- 1

- Views

- 111

- Replies

- 30

- Views

- 1K