H4895 ?Another fail with x39. I think my Norinco just doesn't like cast. Have tried 2400 and IMR4198 powders. IMR4198 cycles the action w/out issue but accuracy sucks. 2400 doesn't cycle the action but accuracy is good. Gonna grab a pound of RL-7 and give that a try.

-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

-

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bullet Casting & Coating MegaThread

- Thread starter 38ExtraSpecial

- Start date

Artie

NES Member

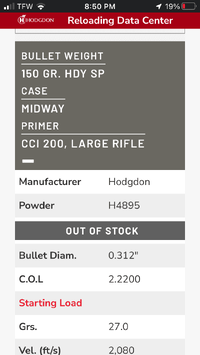

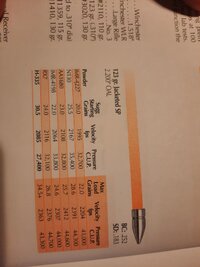

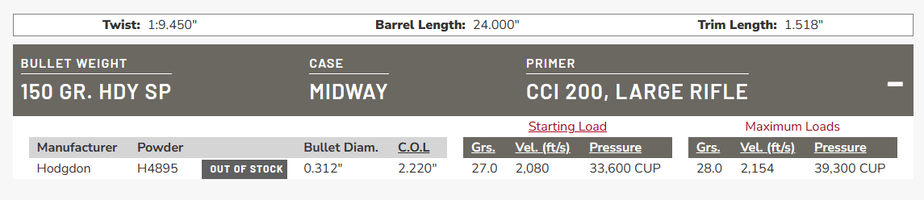

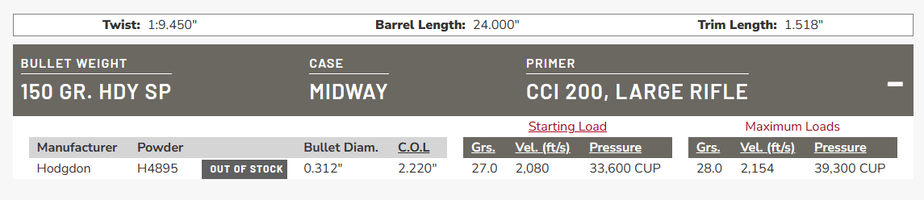

You think that may work well for the Lee cast x39?H4895 ?

Is H4895 good for jacketed x39?You think that may work well for the Lee cast x39?will give it a shot

Artie

NES Member

I don't know. I don't see it in either of my Lyman books. I originally went with C.E. Harris article Practical Dope on the 7.62x39 and decided due to my manuals to try IMR4198. Accuracy was shit. @Jay77 had such good luck with 2400 in his sks and Harris also recommended it, I gave it a try. Good Accuracy but won't cycle the action and I am at the max. I will give anything a shot and RL-7 is in my books and indicted by Harris. I will research H4895 and see what is out there for loads. I have about 8 more manuals to dig thru. Do you have a starting load in mind? ThanksIs H4895 good for jacketed x39?

I thought harris had a load with H4895 ?

Practical Dope on the 7.62X39

Practical Dope on the 7.62x39 By C.E. HarrisUpdated 3-27-94 I have reloaded thousands of rounds of 7.62X39 ammunition with both cast bullets and jacketed, in the AK and the SKS. I got frustrated with the AK as accuracy of these seems is generally poor, at best about 5-6" at 100 yards. The...

castboolits.gunloads.com

Artie

NES Member

That is a narrow range between starting and max loads, 27-28. This is for jacketed so i should start a bit less. A reduced load would be 16.8 but that probably wouldnt run the action either. If it doesnt work out, i can still use it for 308 and 8mm. If it is in stock at my local store, i will give it a try. thanks

Last edited:

Anything within safety is worth a try. I like the H4895 reduced loads in the larger 30 cal cases .That is a narrow range between starting and max loads, 27-28. This is for jacketed so i should start a bit less. A reduced load would be 16.8 but that probably wouldnt run the action either. If it doesnt work out, i can still use it for 308 and 8mm. If it is in stock at my local store, i will give it a try. thanks

View attachment 764442

H4895 should work. It produces much more volume of gas than the faster powders like 2400, red dot and such.

You can do as harris does and up the hardness of your cast loads and up the powder charges.

I think he pushed sks/aka cast to 2000 fps?

Last edited:

ddeck

NES Member

- Joined

- Jan 1, 2022

- Messages

- 1,427

- Likes

- 3,256

Ok, first day casting bullets. RCBS cast iron mold and using straight clip on wheel weight material. Took a few drops to grt the mold up to temp but things stopped being wrinkly after that. The other thing I learned was to leave the lead in the mold for about 15 seconds before knocking off the sprue plate. The bullets seemed to be consistently better after that. Some look like the mold wasn’t fully closed and left a little seam of lead at the top. Anything else anyone see to help me? I didn’t grt any frosting as far as I could tell but I’m a noob. Should they fill out better? Maybe add a bit of tin?

First pic with the first casts at the top…all wrinkly

Second pic with more consistent casting

First pic with the first casts at the top…all wrinkly

Second pic with more consistent casting

38ExtraSpecial

NES Member

Finally. Welcome to the club!Ok, first day casting bullets. RCBS cast iron mold and using straight clip on wheel weight material. Took a few drops to grt the mold up to temp but things stopped being wrinkly after that. The other thing I learned was to leave the lead in the mold for about 15 seconds before knocking off the sprue plate. The bullets seemed to be consistently better after that. Some look like the mold wasn’t fully closed and left a little seam of lead at the top. Anything else anyone see to help me? I didn’t grt any frosting as far as I could tell but I’m a noob. Should they fill out better? Maybe add a bit of tin?

First pic with the first casts at the top…all wrinkly

View attachment 764991

Second pic with more consistent castingView attachment 764992

Ok so that flashing on some of the bullets could be the mould not totally closed. Usually a spec of lead stuck in between the mould faces. It also could be too hot a temp and too much tin which can cause the lead to flow into the vent lines. It’s hard to tell. It does look like there’s some spider webs to that flashing. Which also happens when the mould is help open by the spec of lead.

I wouldn’t bother with tin because the fill out looks awesome.

Keep doing what you’re doing and you’ll notice the little variations that occur when you cast hotter or cooler. Faster or slower.

Casting is all about cadence which you’re quickly figuring out.

Now time to size/lube/load/shoot.

ddeck

NES Member

- Joined

- Jan 1, 2022

- Messages

- 1,427

- Likes

- 3,256

Great! I can see now why people run two moulds at once.Finally. Welcome to the club!

Ok so that flashing on some of the bullets could be the mould not totally closed. Usually a spec of lead stuck in between the mould faces. It also could be too hot a temp and too much tin which can cause the lead to flow into the vent lines. It’s hard to tell. It does look like there’s some spider webs to that flashing. Which also happens when the mould is help open by the spec of lead.

I wouldn’t bother with tin because the fill out looks awesome.

Keep doing what you’re doing and you’ll notice the little variations that occur when you cast hotter or cooler. Faster or slower.

Casting is all about cadence which you’re quickly figuring out.

Now time to size/lube/load/shoot.

The Star lubrisizer is ready to go for these 45s.

Thanks to all of you (as part of the Cast Bullet Seminar) for all the knowledge and assistance!

38ExtraSpecial

NES Member

Yeah once you get it down (you’re there) then run 2 moulds to up your efficiency.Great! I can see now why people run two moulds at once.

The Star lubrisizer is ready to go for these 45s.

Thanks to all of you (as part of the Cast Bullet Seminar) for all the knowledge and assistance!

Then you need 2 lead furnaces. So when one dries up you can swap to the second and let the lead melt down in the first.

Maximum boolits!

Look good, dont worry to much about frosting.Ok, first day casting bullets. RCBS cast iron mold and using straight clip on wheel weight material. Took a few drops to grt the mold up to temp but things stopped being wrinkly after that. The other thing I learned was to leave the lead in the mold for about 15 seconds before knocking off the sprue plate. The bullets seemed to be consistently better after that. Some look like the mold wasn’t fully closed and left a little seam of lead at the top. Anything else anyone see to help me? I didn’t grt any frosting as far as I could tell but I’m a noob. Should they fill out better? Maybe add a bit of tin?

First pic with the first casts at the top…all wrinkly

View attachment 764991

Second pic with more consistent castingView attachment 764992

What @38ExtraSpecial said plus your lead is too hot.Ok, first day casting bullets. RCBS cast iron mold and using straight clip on wheel weight material. Took a few drops to grt the mold up to temp but things stopped being wrinkly after that. The other thing I learned was to leave the lead in the mold for about 15 seconds before knocking off the sprue plate. The bullets seemed to be consistently better after that. Some look like the mold wasn’t fully closed and left a little seam of lead at the top. Anything else anyone see to help me? I didn’t grt any frosting as far as I could tell but I’m a noob. Should they fill out better? Maybe add a bit of tin?

First pic with the first casts at the top…all wrinkly

View attachment 764991

Second pic with more consistent castingView attachment 764992

Looks great for a first try, seriously.

Come to the seminar and learn how to coat those.

I'm in Taunton if you need to size, lube or coat.

ddeck

NES Member

- Joined

- Jan 1, 2022

- Messages

- 1,427

- Likes

- 3,256

What @38ExtraSpecial said plus your lead is too hot.

Looks great for a first try, seriously.

Come to the seminar and learn how to coat those.

I'm in Taunton if you need to size, lube or coat.

Thanks. That was 4.5 on the Lee 4-20. So, i’ll bump it down to 4 and see how it looks. An online resource said between 4 and 5. I don’t have a lead thermometer yet but will get one shortly for better measurements.

I was at the seminar last year and will be back again this year. It just took me forever to get started (mainly just assembling equipment).

38ExtraSpecial

NES Member

Thermometer is a must. My Lee pots run completely different dial wise. They also start dropping lower. Someone on another forum explained how it works and how you can clean the contact points to get it back up to snuff but they won’t stay consistent as they get old and worn is the gist of itThanks. That was 4.5 on the Lee 4-20. So, i’ll bump it down to 4 and see how it looks. An online resource said between 4 and 5. I don’t have a lead thermometer yet but will get one shortly for better measurements.

I was at the seminar last year and will be back again this year. It just took me forever to get started (mainly just assembling equipment).

Cheap thermocouple meter off Amazon is the easiest.Thanks. That was 4.5 on the Lee 4-20. So, i’ll bump it down to 4 and see how it looks. An online resource said between 4 and 5. I don’t have a lead thermometer yet but will get one shortly for better measurements.

I was at the seminar last year and will be back again this year. It just took me forever to get started (mainly just assembling equipment).

Lee pots will get hotter as the lead level drops so you need to keep an eye on it or not let it go below half.

This should make a few bullets.

1 LOT OF LEAD SHEETS

"1 LOT OF LEAD SHEETS TO INCLUDE: FOUR SHEETS 24 X 36 (EST WEIGHT: 133 POUNDS EACH) AND TWO SHEETS 24 X 24 (EST 80 POUNDS EACH). SOLD AS IS."

1 LOT OF LEAD SHEETS

"1 LOT OF LEAD SHEETS TO INCLUDE: FOUR SHEETS 24 X 36 (EST WEIGHT: 133 POUNDS EACH) AND TWO SHEETS 24 X 24 (EST 80 POUNDS EACH). SOLD AS IS."

ddeck

NES Member

- Joined

- Jan 1, 2022

- Messages

- 1,427

- Likes

- 3,256

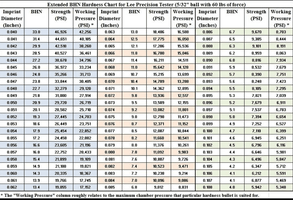

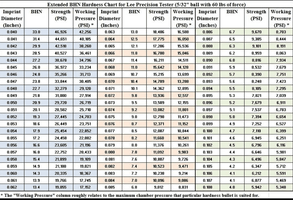

Getting ready to load up these wheel weight bullets I made and I want to make sure I have this correct. This chart from Lee shows the amount of pressure that a particular alloy of lead can withstand, but I want to make double sure I am reading this right. Based on this, if we take the WW as 11 BHN (low end) that means I can have up to 15,000 PSI. From my load manuals, this means I can use Titegroup at 4.5 grains for 230 gn 45 ACP since the pressure is only 10,000 PSI, way under the 15,000. Correct?

38ExtraSpecial

NES Member

You should be fun as long as fit to the barrel is good.

Those low pressure cartridges are forgiving

Those low pressure cartridges are forgiving

You will probably find some of your best loads on the lower side of pressure anyway.Getting ready to load up these wheel weight bullets I made and I want to make sure I have this correct. This chart from Lee shows the amount of pressure that a particular alloy of lead can withstand, but I want to make double sure I am reading this right. Based on this, if we take the WW as 11 BHN (low end) that means I can have up to 15,000 PSI. From my load manuals, this means I can use Titegroup at 4.5 grains for 230 gn 45 ACP since the pressure is only 10,000 PSI, way under the 15,000. Correct?

View attachment 767822

Bullet fit to throat/lead will be more of a factor. 45 acp for me has been very easy with very few issues.

ddeck

NES Member

- Joined

- Jan 1, 2022

- Messages

- 1,427

- Likes

- 3,256

I went to the range today with 93 of the 45 ACP loads. The cast was a 45-230-RN as previously described. I sized to .452 and lubed in my Star lubrasizer with Carnauba Red from WLL. I then loaded with 4.5 gns Titegroup to a COAL of 1.200.

All of the rounds went straight through the paper with no keyholing (at 10 yds). It was a little smoky but all the rounds fired and had no issues. At home, I borescoped the barrel and there was no leading in the barrel.

I’ll make up some more over the holiday and stretch the distance a bit to see if anything changes.

Crazy that even with 7 cent primers…it’s a 10 cent cartridge to make with cast.

All of the rounds went straight through the paper with no keyholing (at 10 yds). It was a little smoky but all the rounds fired and had no issues. At home, I borescoped the barrel and there was no leading in the barrel.

I’ll make up some more over the holiday and stretch the distance a bit to see if anything changes.

Crazy that even with 7 cent primers…it’s a 10 cent cartridge to make with cast.

ThisYou should be fun as long as fit to the barrel is good.

Those low pressure cartridges are forgiving

I load up near +P 9mm in range lead (~11 BHN) without leading by using a coated bullet and a slow(er) powder.

Want some coated to see if it's the lube or the powder creating the excess smoke?I went to the range today with 93 of the 45 ACP loads. The cast was a 45-230-RN as previously described. I sized to .452 and lubed in my Star lubrasizer with Carnauba Red from WLL. I then loaded with 4.5 gns Titegroup to a COAL of 1.200.

All of the rounds went straight through the paper with no keyholing (at 10 yds). It was a little smoky but all the rounds fired and had no issues. At home, I borescoped the barrel and there was no leading in the barrel.

I’ll make up some more over the holiday and stretch the distance a bit to see if anything changes.

Crazy that even with 7 cent primers…it’s a 10 cent cartridge to make with cast.

ddeck

NES Member

- Joined

- Jan 1, 2022

- Messages

- 1,427

- Likes

- 3,256

I'm going to get some Hi-Tek and start doing that in a little bit once I do some more casting and get that down a little better. Building a PID is the next step to ensure proper temp.Want some coated to see if it's the lube or the powder creating the excess smoke?

View attachment 769624

During the Cast Bullet Seminar, it would be helpful to get 20 or so to be able to test it out. Thank you very much for the offer.

38ExtraSpecial

NES Member

Amazing how cheap it is to make good ammo right? Some disagree but we know they’re just stupid.I went to the range today with 93 of the 45 ACP loads. The cast was a 45-230-RN as previously described. I sized to .452 and lubed in my Star lubrasizer with Carnauba Red from WLL. I then loaded with 4.5 gns Titegroup to a COAL of 1.200.

All of the rounds went straight through the paper with no keyholing (at 10 yds). It was a little smoky but all the rounds fired and had no issues. At home, I borescoped the barrel and there was no leading in the barrel.

I’ll make up some more over the holiday and stretch the distance a bit to see if anything changes.

Crazy that even with 7 cent primers…it’s a 10 cent cartridge to make with cast.

Probably the lube causing the smoke. All of that stuff is Smokey but I love the smell of anything with alox in it.

Yes@pastera are you using silhouette in your nine loads. I started playing with it but got some leading but I think that may be a sizing issue.

I went to silhouette because of leading with faster powders.

What are you sizing to?

I don't care much about color so a $20 thermocouple meter and a Walmart toaster oven is all I use for hitek.I'm going to get some Hi-Tek and start doing that in a little bit once I do some more casting and get that down a little better. Building a PID is the next step to ensure proper temp.

During the Cast Bullet Seminar, it would be helpful to get 20 or so to be able to test it out. Thank you very much for the offer.

PM me an address and I'll fill a small flat rate with those bullets and some hitek powder

Jay77

NES Member

.356, I want to say but I have a new batch to size and I might go .357. What I think is the problem might be slightly oversized bullets and some of the hi tek is coming off during sizing on a few. Small hiccup no biggy. Coating a bunch of .357 about 15 pounds give or take.Yes

I went to silhouette because of leading with faster powders.

What are you sizing to?

Share: