Technology marches forever onward. Markforged, as a company, is not likely to change their policy here. Eventually someone (Prusa? Creality?) will make a prosumer model, or maybe even a FOSS one. Until then, metal printers will remain expensive and tightly controlled by their manufacturers.

For reference, here's one of the first hits for "Metal X pricing"

Metal 3D printers have been around for over a decade but have been out of reach for most. With the introduction of the Markforged Metal X, this has begun

www.engineeringclicks.com

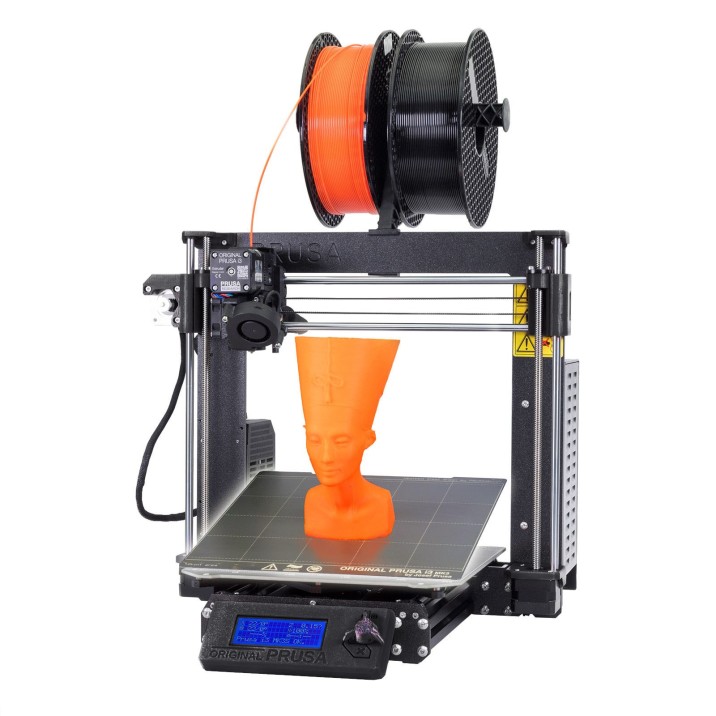

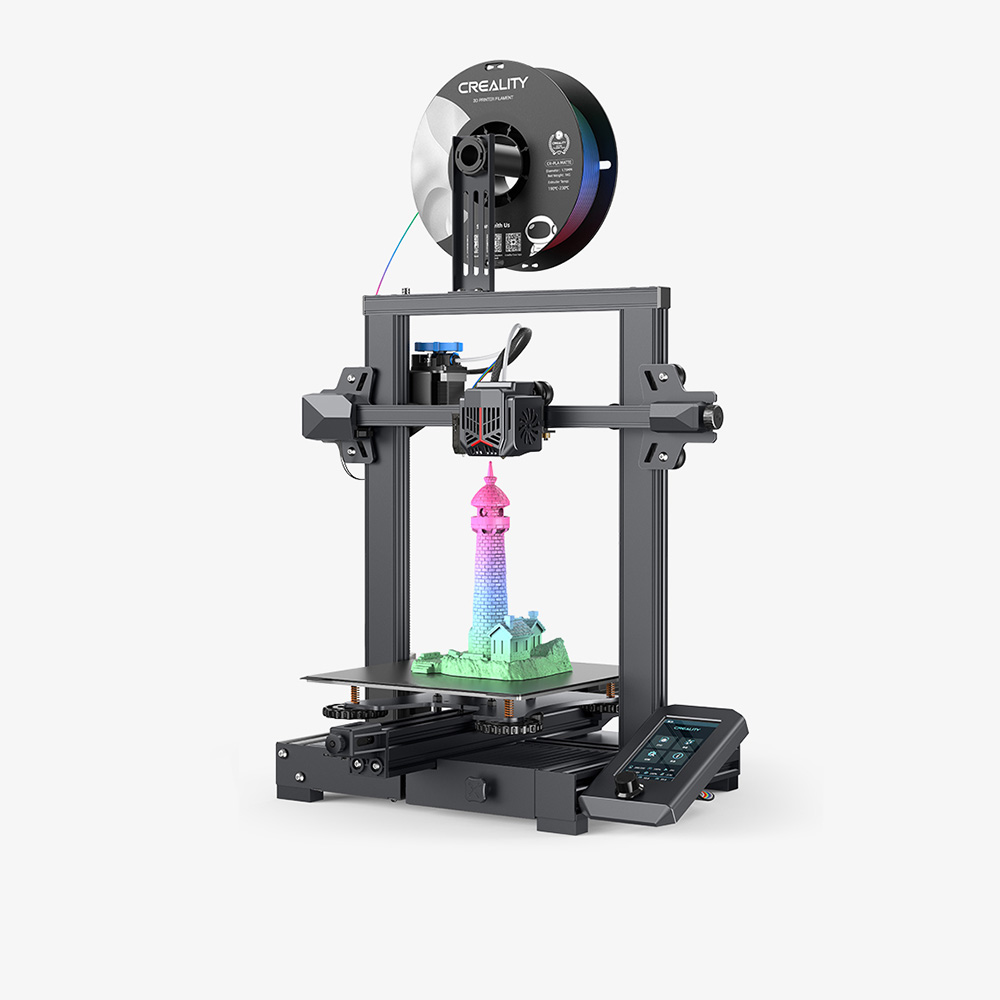

$120K for the system. $130 to $330 per spool of material. For comparison, you can have a brand new, assembled Prusa drop-shipped to your door for a bit over $1K, and each spool of material is ~$20-$30.