-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

-

Be sure to enter the NES/MFS June Giveaway ***Keltec SUB2000***

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone here paper patching bullets?

- Thread starter 38ExtraSpecial

- Start date

38ExtraSpecial

NES Member

Depending on the paper you use it will clean up the bore. There is a good read on a few forums called Paper 101 and it explains the different materials used in paper making and how some are abrasive. Probably super fine and very mild abrasive but they can clean up a bore really nice.I got about as far as you. I don't even know where my paper is now. I also thought would wrapping them in 3000grit emry cloth clean up the bore a bit?

I patched some 405, 485, and 535 grain bullets that The Goose gave me for the 45/70. They were already lubed but I wanted to roll a couple to mess with some technique a bit.

I think I have my patches figured out now and I need to borrow a buddy's mould so I can have some non lubed bullets to try.

When I wrapped the bullets up further to the ogive they were too fat to get into the short throat of my rifle easily. They were very tight but they did chamber enough to raise the breech block.

The 483 and 535 grain bullets have a bore ride section that's about .445 in diameter. I think if I wrap to that section and not the ogive then I should be able to chamber the round without difficulty and still have the effect of the patch tapering onto that bore ride section as if it were the ogive.

Just Bob Lee Swagger.

That would be a great user name....

I've been watching a ton of videos and reading a ton online about patching. Of course The Shooter clip came up with the old man talking about paper patched bullets.

I don't think it's as common really but people do paper patch jacketed bullets to keep down on copper fouling in rifles, especially the heavy overbore cartridges.

What is the advantage of paper patching?

38ExtraSpecial

NES Member

The paper acts like a copper jacket and protects the lead core. No lube needed. No leading.

Apparently you can push cast damn fast, some claiming to do so at 3000 FPS and still have 1 MOA accuracy.

If you hunt it's a good way to use near dead soft lead and push it very fast without the bullet skidding in the rifling and causing leading and inaccuracy. With such soft lead a hollow point can turn inside out on itself and still hold together well compared to alloys with antimony which can get brittle. There are a couple pics of paper patched hollow points on the hollow point picture thread on castboolits. impressive.

It's also a good way to get some over sized bores to shoot well without having to get a custom mould. You can use a mould that drops .309 bullets and patch up to use in the sewer tubes of old mosins or similar military rifles that had poor quality control and lots of corrosive ammo shot through them.

I've read that some guys even paper patch jacketed bullets in over bore cartridges to keep down on copper fouling.

For smokeless paper patching you want to have a bullet size to about .001" over the BORE diameter. Then patch with a paper that lands you at or a little above GROOVE + .001" or .002"

If the patched diameter is a little bigger than that you can always size the patched bullet down.

I'm sizing my lee 457-405s down to .453" (the size I was using in my 1911) and patching with tracing paper. The end up just about spot on to .460" So I can pas them through the sizer with a tiny dab of bore butter just to kind of iron some into the patch. Seems to me this helps with loading them.

I also tried using some 100% Rag vellum and patched it ran about .465" So when I was done I ran the bullet through the .460" sizer and was ready to load.

I don't know if either of these papers are going to work well or if I'm even doing it right but accord to the great inter webs it looks like you don't have to be too critical on how you do it, just keep it consistent from one bullet to the next.

Black Powder is different. I want to say you size the bullet under the bore diameter so when it's patched it up to bore diameter. Dead soft lead is used. The black powder obdurates the bullet to fill the bore. I'm not planning on shooting BP anytime so I haven't bothered much with it

Eddie you could patch your .500 S&W and run some 700 grain dead soft hollow points at speeds that will make your eyes bleed. Who needs copper jackets?

Apparently you can push cast damn fast, some claiming to do so at 3000 FPS and still have 1 MOA accuracy.

If you hunt it's a good way to use near dead soft lead and push it very fast without the bullet skidding in the rifling and causing leading and inaccuracy. With such soft lead a hollow point can turn inside out on itself and still hold together well compared to alloys with antimony which can get brittle. There are a couple pics of paper patched hollow points on the hollow point picture thread on castboolits. impressive.

It's also a good way to get some over sized bores to shoot well without having to get a custom mould. You can use a mould that drops .309 bullets and patch up to use in the sewer tubes of old mosins or similar military rifles that had poor quality control and lots of corrosive ammo shot through them.

I've read that some guys even paper patch jacketed bullets in over bore cartridges to keep down on copper fouling.

For smokeless paper patching you want to have a bullet size to about .001" over the BORE diameter. Then patch with a paper that lands you at or a little above GROOVE + .001" or .002"

If the patched diameter is a little bigger than that you can always size the patched bullet down.

I'm sizing my lee 457-405s down to .453" (the size I was using in my 1911) and patching with tracing paper. The end up just about spot on to .460" So I can pas them through the sizer with a tiny dab of bore butter just to kind of iron some into the patch. Seems to me this helps with loading them.

I also tried using some 100% Rag vellum and patched it ran about .465" So when I was done I ran the bullet through the .460" sizer and was ready to load.

I don't know if either of these papers are going to work well or if I'm even doing it right but accord to the great inter webs it looks like you don't have to be too critical on how you do it, just keep it consistent from one bullet to the next.

Black Powder is different. I want to say you size the bullet under the bore diameter so when it's patched it up to bore diameter. Dead soft lead is used. The black powder obdurates the bullet to fill the bore. I'm not planning on shooting BP anytime so I haven't bothered much with it

Eddie you could patch your .500 S&W and run some 700 grain dead soft hollow points at speeds that will make your eyes bleed. Who needs copper jackets?

Paper acts as a jacket . Excuse my memory from 25 ish years ago . I used to shoot a 1 part tin to 20 partspure lead . The paper kept the soft bullet from leading and formed a seal . This was for a 45/110 sharps . Lube was lard and bees wax mix.

Eddie you could patch your .500 S&W and run some 700 grain dead soft hollow points at speeds that will make your eyes bleed.

I do that anyway without patching.

38ExtraSpecial

NES Member

I do that anyway without patching.

Good point.

Oh and the most inportant benefit. It looks cool as hell. Problem is I want to ream my Sharps to 45-120 now.

I bought a paper patch mould for .30 cal to try in the '06 but never found a local source for paper to suit it.

I guess it should be bumped up the ole priority list a bit.

PP lead bullets aught to come in at less than $.02 per each.

Jack

I guess it should be bumped up the ole priority list a bit.

PP lead bullets aught to come in at less than $.02 per each.

Jack

38ExtraSpecial

NES Member

I found good tracing and vellum at Office Depot.

The more people get into it the more I hear that just about anytning works ok.

People are less strict than what they were in the past. Seems you can make it all work well.

The more people get into it the more I hear that just about anytning works ok.

People are less strict than what they were in the past. Seems you can make it all work well.

38ExtraSpecial

NES Member

Shot the first test rounds tonight. Lee 457-405

I had some coated with hi-tek and some of the same bullets patched. They both shot about the same. 2" group or so at 50 yards. I was resting on a range bag and losing light (not good with a Soule tang sight) (excuses)

The bore was shiny and I found some scraps of patch on the ground about 5' in front of the bore. I shot some more and found more patch material later which was much cleaner than the first batch. They're not kidding when they say the paper cleans fouling from the bore.

I had some coated with hi-tek and some of the same bullets patched. They both shot about the same. 2" group or so at 50 yards. I was resting on a range bag and losing light (not good with a Soule tang sight) (excuses)

The bore was shiny and I found some scraps of patch on the ground about 5' in front of the bore. I shot some more and found more patch material later which was much cleaner than the first batch. They're not kidding when they say the paper cleans fouling from the bore.

38ExtraSpecial

NES Member

Big thanks to 191FAN for letting me borrow some moulds. Lending a nice mould is like lending a girlfriend. People don't usually do it.

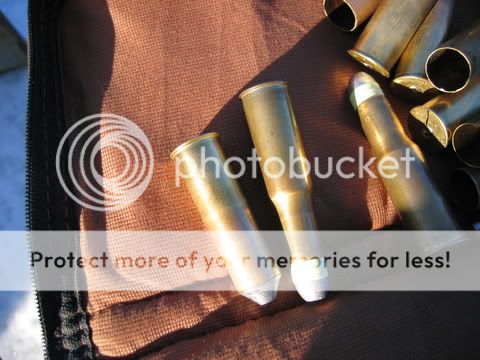

I wrapped a few test patch lengths. I want to see how long I can wrap and still chamber freely. The longer two chambered a little tight, extracted a little hard (not that you would normally remove the case before firing) and showed some rifling marks on the patch. Not a big deal. The shorted chambered freely and extracted freely. This bullet has a reduce bore ride section in front of the first driving band which give room for the patch to shrink onto to aid in chambering and alignment in the throat.

I wrapped a few test patch lengths. I want to see how long I can wrap and still chamber freely. The longer two chambered a little tight, extracted a little hard (not that you would normally remove the case before firing) and showed some rifling marks on the patch. Not a big deal. The shorted chambered freely and extracted freely. This bullet has a reduce bore ride section in front of the first driving band which give room for the patch to shrink onto to aid in chambering and alignment in the throat.

38ExtraSpecial

NES Member

smokeless.

- - - Updated - - -

Black powder uses a little different sizing. Generally the bullet is sized under bore and patched to bore diameter. Soft lead. the black powder bumps the bullet up to fill the rifling on firing.

- - - Updated - - -

Black powder uses a little different sizing. Generally the bullet is sized under bore and patched to bore diameter. Soft lead. the black powder bumps the bullet up to fill the rifling on firing.

38ExtraSpecial

NES Member

So I've been trying more papers and methods of wetting the paper. Super fun.

I've missed the range for 3 weeks so I haven't been able to test loads but I should be able to work some up and shoot them this week.

I've missed the range for 3 weeks so I haven't been able to test loads but I should be able to work some up and shoot them this week.

That would make Townsend Whelen proud,Great job.

38ExtraSpecial

NES Member

Does plastic patching (sabots) qualify?

Pretty close. Just not a inexpensive

Loading those 22LRs with a stouter rifle load, they shed the sabot more reliably.

Even though I can't hit much at 100 meters, they do run quite true. They also rival wadcutters for crisp holes in paper and really do a number on water-filled cans:

Those are used sabots that I refired, so I'm surprised the bullets stabilized so well at this distance. Perhaps I'll use new sabots as I progress along...

Even though I can't hit much at 100 meters, they do run quite true. They also rival wadcutters for crisp holes in paper and really do a number on water-filled cans:

Those are used sabots that I refired, so I'm surprised the bullets stabilized so well at this distance. Perhaps I'll use new sabots as I progress along...

Last edited:

Share: