Thank you for the info. This is a Tikka T3.so, just one comment.

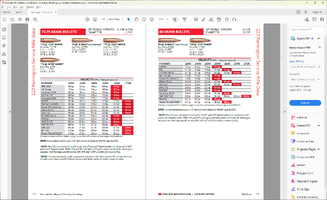

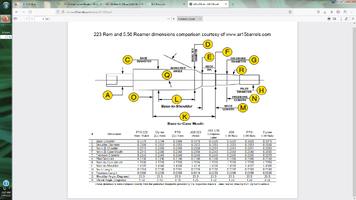

if 2.330" up there is a COAL - the 69SMK does not like to sit that high. it is really best at 2.260-2.275 COAL.

if you prefer to sit bullet that high to be closer to the lands - you can look at nosler RDF lineup.

also, groups sizes you see are similar to what i had initially trying 2520, and why i switched to varget - that worked for my ar15, but you have a bolt gun here. so, dunno.

if it is NOT a bolt gun - then sit it for the mag at 2.260-2.265, where it belongs.

This is the first time I've played around with seating something longer than mag length. In reading about various bullets, I gather the 69SMK and 77SMK were meant to be loaded mag length for AR15 service rifle / highpower competition. I grabbed them intending to load them in an AR, but they are the only higher weight 22 bullets I have on hand so gave them a whirl.

![Troll [troll] [troll]](/xen/styles/default/xenforo/smilies.vb/016.gif)