- Joined

- Nov 10, 2010

- Messages

- 1,032

- Likes

- 1,003

https://www.dupagetrading.com/m1-stocks/m1-stock-sets.html

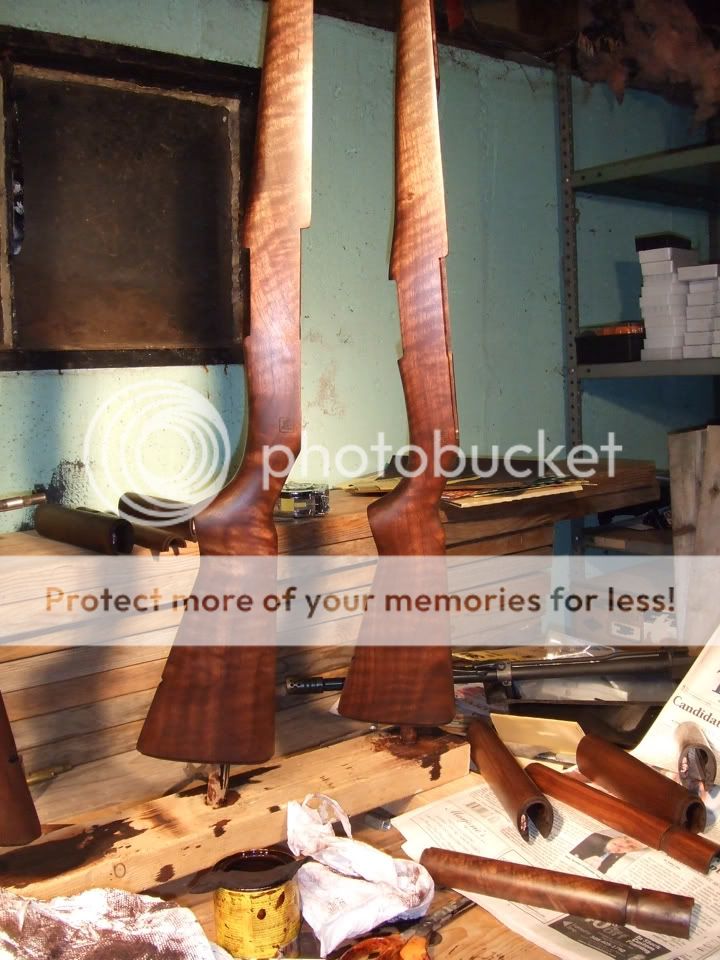

Dupage makes stock sets for the CMP. You can buy them with or without metal. They are a nice stock set straight out of the box, and they come pre-finished if that's what you want––but you can also order an unfinished set and put a bit more love, sweat, and workmanship into it.

I spent a quality day in the shop working on some of them.

Everybody has their own way of going about going about the job of finishing an unfinished stock, but my personal preference is to sand the wood well to close the grain, working progressively finer grits––I go 100/150/220/320/400/600) and then I like to apply a coat or two of Minwax Red Mahogany Stain.

There is no real trick to staining––you just get the wood good and wet, let it penetrate for awhile (5 -15 minutes) then wipe off the excess––whatever has not penetrated should be buffed off with cheesecloth, an old t-shirt, or paper towels.

Looking at the Minwax color chart you wouldn't think Red Mahogany would work out too well––but it sure does. It just pops a bit more than a standard run-of-the-mill dark walnut.

I think the key to a nice stain job (and where most guys go wrong) is that they leave too much stain on the surface. That isn't where you want the stain––you want the stain deep in the grain––but buff it off the very surface of the wood, so that the stain doesn't just create a monotonous uniformity.

The stain renders deep browns and reds and (with Red Mahogany) a faint reddish-purple undertone––but buffing off the excess will bring forth the lighter tones––the flecks of yellow in the grain.

I'll finish with 3 or 5 coats of Tung oil on the outside, and maybe a couple coats of varnish in the barrel channel, under the butt-plate, and under the front ferrule.

Last thoughts––replacement wood isn't just about aesthetics. If you are interested in accurizing your Garand, a replacement stock set is a real good place to begin––especially if you have a loose original GI stock with mediocre lock-up.

I'd say the Garand stock probably makes the biggest contribution to accuracy of all the various elements of the equation––a rifle with a Kreiger barrel will shoot like a rack grade if it is in a bad or a poorly fitted stock.

If you want to pick up a new unfinished stock set and try your hand at custom finishing but want more info, I'd be happy to post my own personal preferences, tricks, and observations (assuming anybody is interested).

––Warm_Garand

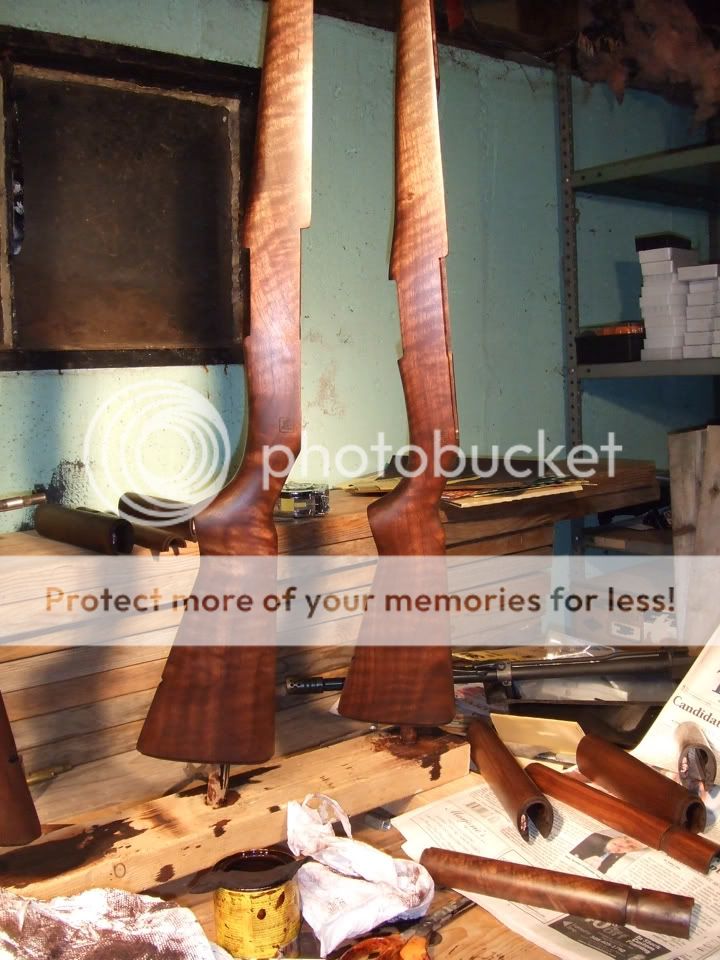

Dupage makes stock sets for the CMP. You can buy them with or without metal. They are a nice stock set straight out of the box, and they come pre-finished if that's what you want––but you can also order an unfinished set and put a bit more love, sweat, and workmanship into it.

I spent a quality day in the shop working on some of them.

Everybody has their own way of going about going about the job of finishing an unfinished stock, but my personal preference is to sand the wood well to close the grain, working progressively finer grits––I go 100/150/220/320/400/600) and then I like to apply a coat or two of Minwax Red Mahogany Stain.

There is no real trick to staining––you just get the wood good and wet, let it penetrate for awhile (5 -15 minutes) then wipe off the excess––whatever has not penetrated should be buffed off with cheesecloth, an old t-shirt, or paper towels.

Looking at the Minwax color chart you wouldn't think Red Mahogany would work out too well––but it sure does. It just pops a bit more than a standard run-of-the-mill dark walnut.

I think the key to a nice stain job (and where most guys go wrong) is that they leave too much stain on the surface. That isn't where you want the stain––you want the stain deep in the grain––but buff it off the very surface of the wood, so that the stain doesn't just create a monotonous uniformity.

The stain renders deep browns and reds and (with Red Mahogany) a faint reddish-purple undertone––but buffing off the excess will bring forth the lighter tones––the flecks of yellow in the grain.

I'll finish with 3 or 5 coats of Tung oil on the outside, and maybe a couple coats of varnish in the barrel channel, under the butt-plate, and under the front ferrule.

Last thoughts––replacement wood isn't just about aesthetics. If you are interested in accurizing your Garand, a replacement stock set is a real good place to begin––especially if you have a loose original GI stock with mediocre lock-up.

I'd say the Garand stock probably makes the biggest contribution to accuracy of all the various elements of the equation––a rifle with a Kreiger barrel will shoot like a rack grade if it is in a bad or a poorly fitted stock.

If you want to pick up a new unfinished stock set and try your hand at custom finishing but want more info, I'd be happy to post my own personal preferences, tricks, and observations (assuming anybody is interested).

––Warm_Garand

Last edited: