NH Phantom

NES Member

Looking for the best and fastest way to sort brass. Especially 380 from 9mm

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

Thanks just found it. I'm downloading files nowYou can't beat the sale price MIdway is having for those at the moment. If you wanted to print some, you can do these. But they won't get the 380's out

Brass Case Sorter by Surrogate

A great job by macobaco on the original design. I remixed it to make it more like the commercially available ammo sorter. There are 3 stacking trays. The top one separates .45 ACP cases. The middle one will separate .40 S&W/10mm and the bottom tray will catch 9mm/.38. Trash and .22LR cases...www.thingiverse.com

On here, we designed a 380 sorter that works on a different principle:

Sorting Brass 2.0

I have the shell sorter: Shell Sorter™ sorts your brass by caliber, saving you time, shoot more It’s great and I love how low tech it is. You just need to wear a mask when using it. Now I’m looking for a method to find the few .380’s that make it into my 9mm bucket which is what this device is...www.northeastshooters.com

That thread has all the info you need on this topic.

I just noticed that they loaded a smaller than 9 that can be used for 380You can't beat the sale price MIdway is having for those at the moment. If you wanted to print some, you can do these. But they won't get the 380's out

Brass Case Sorter by Surrogate

A great job by macobaco on the original design. I remixed it to make it more like the commercially available ammo sorter. There are 3 stacking trays. The top one separates .45 ACP cases. The middle one will separate .40 S&W/10mm and the bottom tray will catch 9mm/.38. Trash and .22LR cases...www.thingiverse.com

On here, we designed a 380 sorter that works on a different principle:

Sorting Brass 2.0

I have the shell sorter: Shell Sorter™ sorts your brass by caliber, saving you time, shoot more It’s great and I love how low tech it is. You just need to wear a mask when using it. Now I’m looking for a method to find the few .380’s that make it into my 9mm bucket which is what this device is...www.northeastshooters.com

That thread has all the info you need on this topic.

In that other thread @pastera indicated that the 3d printing isn’t fine enough to be able to catch the 9’s but not the 380s.I just noticed that they loaded a smaller than 9 that can be used for 380

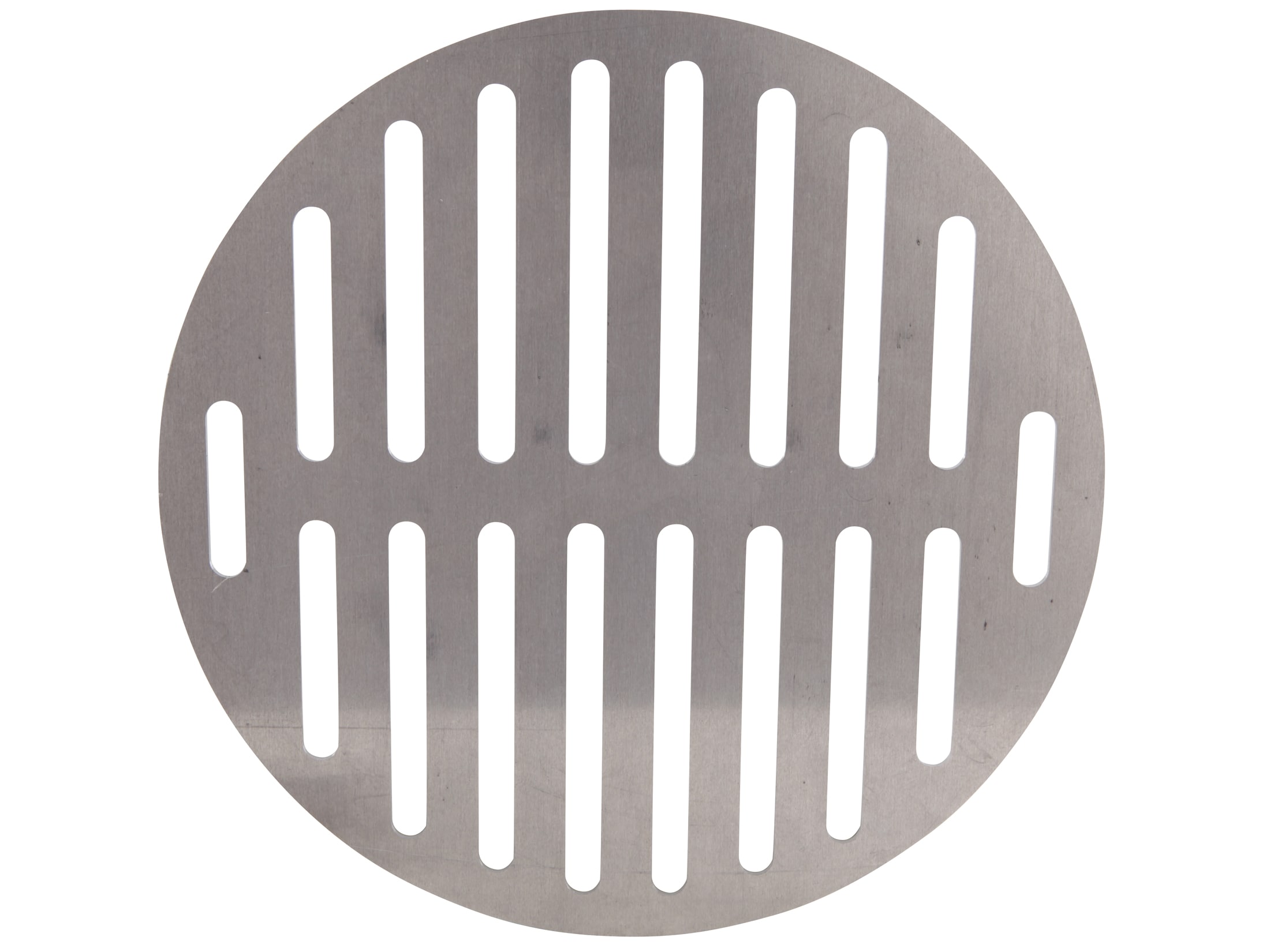

That plate is now on thingiverseIn that other thread @pastera indicated that the 3d printing isn’t fine enough to be able to catch the 9’s but not the 380s.

Which i have no reason to doubt, hence the metal plate being the best option for that. Or my goofball little thing to catch the 9mm “corto”

There is very little difference between 9mm and 380 so a printed sorter might need some hand filing work to perfectThat plate is now on thingiverse

I'll give it a shot and report backThere is very little difference between 9mm and 380 so a printed sorter might need some hand filing work to perfect

i can bring the ones i printed to the seminar and you can try them out if you want. I even printed the 40 in a different color. I think mine took 20 hours to print. PETGPrinting the 9mm sorter now. 16 hours or so. See how she works before I print up the rest.

I printed the bottom of the one you posted. Top printing now. Will be done in a couple hoursi can bring the ones i printed to the seminar and you can try them out if you want. I even printed the 40 in a different color. I think mine took 20 hours to print. PETG

I got a commercially made one in a lot and the only real benefit is that it is a bigger tray. Works about as well.

Thank you. I’ll probably print all of them by then though. I haven’t been using my printer much so it’s nice to run it.i can bring the ones i printed to the seminar and you can try them out if you want. I even printed the 40 in a different color. I think mine took 20 hours to print. PETG

I got a commercially made one in a lot and the only real benefit is that it is a bigger tray. Works about as well.

No problem. The biggest issue was filing the 45 and 40 ones so that the smaller ones would fall through. If you have a better first layer than I got you may not have to do any filing. It was slightly tedious to file all of the slots.Thank you. I’ll probably print all of them by then though. I haven’t been using my printer much so it’s nice to run it.

I’m printing the same set plus the 380 started this morning. Will be done in the morning. Ah the advantage of having 6 printers.45 sorter almost printed. About an hour faster estimate due to the larger slots. See 45 wins again!!

Maybe I should alter the Fotay file to 10mm so I don’t feel so Ghey

@Broc does that pass the test or not?

Wow that’s a nice set up.I’m printing the same set plus the 380 started this morning. Will be done in the morning. Ah the advantage of having 6 printers.

I don't think you have to print the 9mm one. The 380 one will catch the 9mm. 380's go about half way through. A small bit of sanding or filing should clean that upWow that’s a nice set up.

Let me know how the 380 plate works. I’m wondering how close the tolerances need to be.

I don't think you have to print the 9mm one. The 380 one will catch the 9mm. 380's go about half way through. A small bit of sanding or filing should clean that up

Interesting. So 223 doesn’t go through the 9mm bin but goes through the 380 bin?223 will go through the 380 unlike the 9mm

correct the 9 bin is smaller than the 380Interesting. So 223 doesn’t go through the 9mm bin but goes through the 380 bin?

| 380 | 9mm | |

|---|---|---|

| Bullet Diameter | .355 in (9.0 mm) | 0.355 in (9.01 mm) |

| Neck Diameter | .373 in (9.5 mm) | 0.380 in (9.65 mm) |

| Base Diameter | .374 in (9.5 mm) | 0.391 in (9.93 mm) |

I have to measure my print now. I did a quick test with the 45 and 9 mm plates. The 556 will not slide through. Even with a little pressure. I’ll take some measurements and try to re-print a few percent larger if need be9mm: .394

380: .374

223: .378

A slot that's 0.385+/-0.005 should drop 380 and 223 but hold 9mm