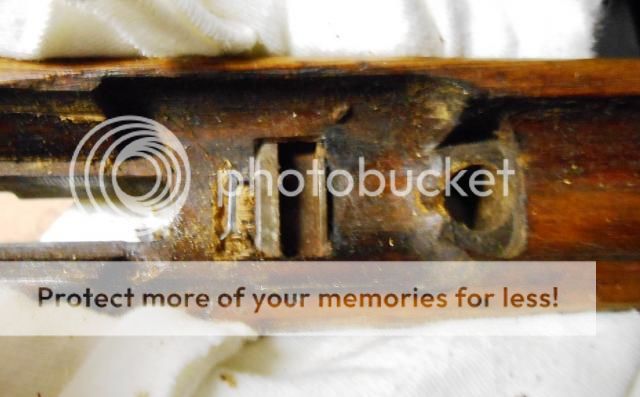

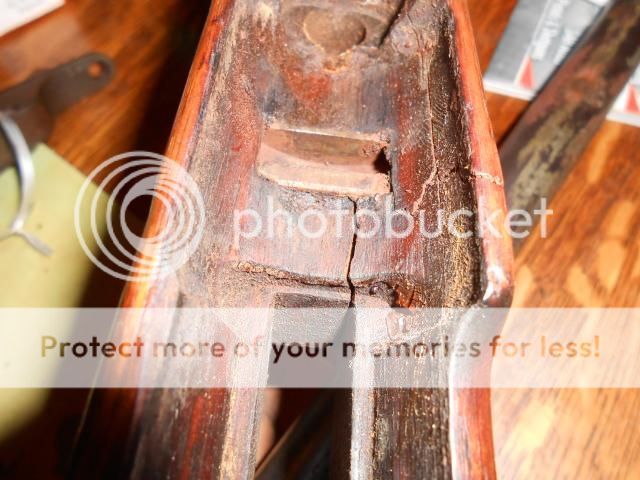

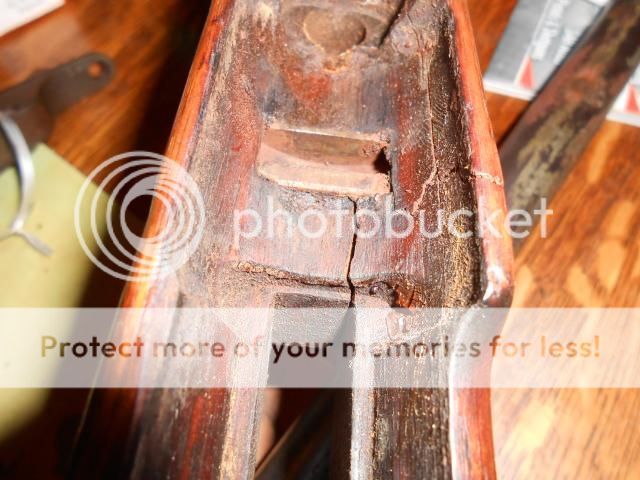

Kar88 came yesterday. Tough shape. Rusted pitted barrel, and the crack is all the way through the stock. Part of the nose piece fell off, and neither the stub of the band pin or the cross bolt disc would move. Barrel jacket will not move. Very dry metal with scattered surface rust. I glued the nose piece on last night.

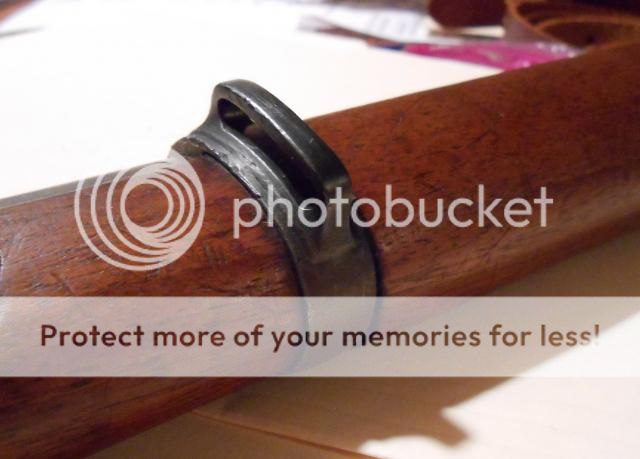

Got a lot of work to do. Tonight I worked on the broken band spring. I took several finishing nails and cut a couple down to one inch and using a pair of lock pliers, gently began tapping the head onto the pin. Turned out to be a rusty mess, causing the pin to bond with the wood and snap in half. It was like playing a game of operation. I knew something was wrong when the wood began to bulge on the spring side - I gently tapped that back with the butt of a screwdriver. I had removed the pin head, but saw part of the pin still inside. In trying to reverse punch, a large chip fell of the other side of the stock.

In trying to fit the new band spring, I found it was too tight. I had to ream the end of the slot for it to fit. Now I had to deal with the triple size pin hole on the other side. I filled the hole with glue and the broken piece of pin and part of a nail to support the new pin. I carefully glued the broken chip back, and then made a paste of the glue and the sawdust and using a wooden splint I filled the remaining gaps. A touch of sanding and Minwax gun-stock stain will finish this part off.

When my friend's band gets here, I'll send it off with the original to have the sling bar laser welded and restored by Pullman Arms in Worcester.

The next step is to somehow remove the crossbolt and begin to work on the crack that looks like an H, but missing the upper left and lower right tips. I have the Acra-glass waiting.

Thanks for the look and or sympathy.

T

Got a lot of work to do. Tonight I worked on the broken band spring. I took several finishing nails and cut a couple down to one inch and using a pair of lock pliers, gently began tapping the head onto the pin. Turned out to be a rusty mess, causing the pin to bond with the wood and snap in half. It was like playing a game of operation. I knew something was wrong when the wood began to bulge on the spring side - I gently tapped that back with the butt of a screwdriver. I had removed the pin head, but saw part of the pin still inside. In trying to reverse punch, a large chip fell of the other side of the stock.

In trying to fit the new band spring, I found it was too tight. I had to ream the end of the slot for it to fit. Now I had to deal with the triple size pin hole on the other side. I filled the hole with glue and the broken piece of pin and part of a nail to support the new pin. I carefully glued the broken chip back, and then made a paste of the glue and the sawdust and using a wooden splint I filled the remaining gaps. A touch of sanding and Minwax gun-stock stain will finish this part off.

When my friend's band gets here, I'll send it off with the original to have the sling bar laser welded and restored by Pullman Arms in Worcester.

The next step is to somehow remove the crossbolt and begin to work on the crack that looks like an H, but missing the upper left and lower right tips. I have the Acra-glass waiting.

Thanks for the look and or sympathy.

T

Last edited: