I have the shell sorter: Shell Sorter™ sorts your brass by caliber, saving you time, shoot more

It’s great and I love how low tech it is. You just need to wear a mask when using it.

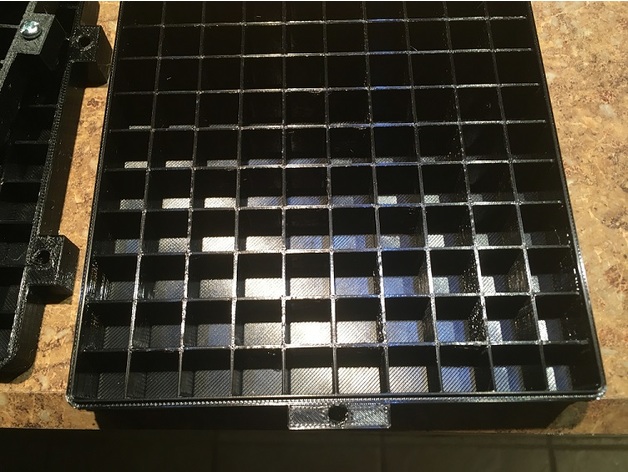

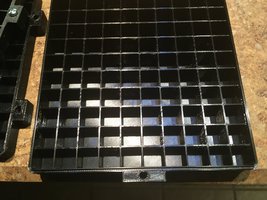

Now I’m looking for a method to find the few .380’s that make it into my 9mm bucket which is what this device is made for: www.utleysort.com

Video in use:

View: https://youtu.be/i5PS06ZX0b0

I also noticed that if flipped over, the device could be used for quickly identifying desirable head-stamps from undesirables cases. Which would be great for those brass snobs out there (you know who you are).

Has anyone else used this utleysort device or made one yourself? He is asking $25 plus shipping. This might be a candidate for 3D printing at the local library. A quick search on thingieverse.com turned up no plans for this yet.

It’s great and I love how low tech it is. You just need to wear a mask when using it.

Now I’m looking for a method to find the few .380’s that make it into my 9mm bucket which is what this device is made for: www.utleysort.com

Video in use:

View: https://youtu.be/i5PS06ZX0b0

I also noticed that if flipped over, the device could be used for quickly identifying desirable head-stamps from undesirables cases. Which would be great for those brass snobs out there (you know who you are).

Has anyone else used this utleysort device or made one yourself? He is asking $25 plus shipping. This might be a candidate for 3D printing at the local library. A quick search on thingieverse.com turned up no plans for this yet.

Last edited: