From the Firearm Blog,

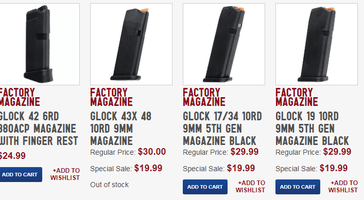

Over at my second digital family – AR15.com – one user has started making his own GLOCK magazineswith a stock 3D Printer, some filament and CAD files released by a group called Deterrence Dispensed. The end result are functional 3D Printed GLOCK magazines that may not look as polished as a factory specimen, but feed rounds all the same. Of course, the metal spring will need to come from an outside source – for the time being.

Can’t Stop The Signal: DIY 3D Printed GLOCK Magazines

Over at my second digital family – AR15.com – one user has started making his own GLOCK magazineswith a stock 3D Printer, some filament and CAD files released by a group called Deterrence Dispensed. The end result are functional 3D Printed GLOCK magazines that may not look as polished as a factory specimen, but feed rounds all the same. Of course, the metal spring will need to come from an outside source – for the time being.

Can’t Stop The Signal: DIY 3D Printed GLOCK Magazines