I picked up a few wooden FAL stocks cheap. Being 50 years old they have a few dents and dings. I heard you can use an iron and a wet cloth to remove dents from wood. So I picked up a $6.99 Iron at Walmart. Anyone attempt this before? Any tips before I give it a try?

-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Using A Iron To Restore Wood Gunstock

- Thread starter FNHFAL

- Start date

Keep the iron moving,don't just let it sit..and ya it works.

Now post pics of your FAL

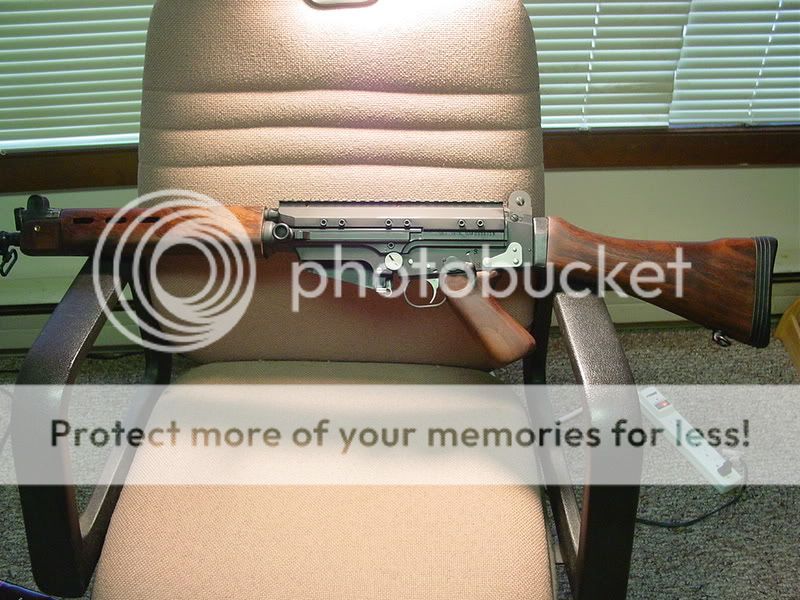

i'll go first,here is a pic of my FAL in a pink chair.

Very nice wood, That has got to be Iron wood or Blue Monster? Pistol grip maybe original?

The steam will raise the grain in the dents. Remember, this will only work properly if the wood fibers are not crushed too badly.

That looks like a comfortable pink chair. Is it in a office?

Run them through your dishwasher when your wife isn't home. Works great.

greencobra

NES Member

- Joined

- Jul 2, 2011

- Messages

- 27,221

- Likes

- 26,718

i've tried this a few times years ago. never got the results i was hoping for. yeah, the wood raised a bit but you still saw the ding somewhat. back in the day, gun writers use to always mention this method in filler articles for their magazines but hell, i never could make it work. just got to try it for yourself...results may vary. ![Grin [grin] [grin]](/xen/styles/default/xenforo/smilies.vb/041.gif)

![Grin [grin] [grin]](/xen/styles/default/xenforo/smilies.vb/041.gif)

IF there is a finish on the wood your results will be marginal at best. Plus, the steam created by the damp cloth could get embedded below your finish (even a cured oil finish) and make a white spot. If the wood is unfinished your results will be much better but even then not perfect if the fibers are compressed too deeply.

**** I know that Willlbedavis was foolin around here. Dishwashers are not a place for any stock. Just makin b sure.*********

Wood stocks get dents. It's part of their history. Wood is wood, too. I've seen Garand stocks that were used to drive tent pegs into the hard ground before but remained still very serviceable albeit a bit less attractive than a non-beat up stock. Dents never bothered me much. Cracks, otoh, must be addressed.

Rome

**** I know that Willlbedavis was foolin around here. Dishwashers are not a place for any stock. Just makin b sure.*********

Wood stocks get dents. It's part of their history. Wood is wood, too. I've seen Garand stocks that were used to drive tent pegs into the hard ground before but remained still very serviceable albeit a bit less attractive than a non-beat up stock. Dents never bothered me much. Cracks, otoh, must be addressed.

Rome

IF there is a finish on the wood your results will be marginal at best. Plus, the steam created by the damp cloth could get embedded below your finish (even a cured oil finish) and make a white spot. If the wood is unfinished your results will be much better but even then not perfect if the fibers are compressed too deeply.

**** I know that Willlbedavis was foolin around here. Dishwashers are not a place for any stock. Just makin b sure.*********

Wood stocks get dents. It's part of their history. Wood is wood, too. I've seen Garand stocks that were used to drive tent pegs into the hard ground before but remained still very serviceable albeit a bit less attractive than a non-beat up stock. Dents never bothered me much. Cracks, otoh, must be addressed.

Rome

The dishwasher thing works.

Sent from my SPH-L900 using Tapatalk

The dishwasher thing works.

Sent from my SPH-L900 using Tapatalk

Good luck with that. Some woods will swell so much with all that hot water, you'll never get parts to go back together correctly.

As a professional woodworker for over 25 years, a C&R holder and restorer of well over 100 stocks, I must tell you that putting a stock in a dishwasher is foolish and destructive. Wood is nothing more than a hard sponge and exposing it to hot water for any length of time will waterlog and ruin a stock, maybe not when it comes out but as it dries out. As I've said, some have been successful. I can see where a humid, soaking wet environment might swell out dings and dents but you also expose yourself to cracks, checks, twists and warps. I'm not going to get into a flame war here but I will tell you that there isn't much more a destructive thing you can expose a wood stock to as there is in a dishwasher. Why not just throw it into the bathtub or swimming pool or, what the heck, the closest river. Nonsense. Wood will respond and not in a way that you will be happy with. I'd stake my 25 years of professional furniture finishing on it.

Rome aka Cabinetman.

Rome aka Cabinetman.

Good luck with that. Some woods will swell so much with all that hot water, you'll never get parts to go back together correctly.

While I truly respect cabinetman's expertise in this area, for hacks like me the dishwasher method has in fact produced acceptable results.

I've done this with three or four garand stocks over the years. Let it dry for a few days. Light sanding. Linseed oil hand rub.

For smaller dents I've always had luck by using a wet rag and a soldering iron. much more targeted approach than the iron. Wet the rag (t-shirt thickness), lay it over the dent, and lightly touch the dent while wanding back and forth. Out it comes...

As a professional woodworker for over 25 years, a C&R holder and restorer of well over 100 stocks, I must tell you that putting a stock in a dishwasher is foolish and destructive. Wood is nothing more than a hard sponge and exposing it to hot water for any length of time will waterlog and ruin a stock, maybe not when it comes out but as it dries out. As I've said, some have been successful. I can see where a humid, soaking wet environment might swell out dings and dents but you also expose yourself to cracks, checks, twists and warps. I'm not going to get into a flame war here but I will tell you that there isn't much more a destructive thing you can expose a wood stock to as there is in a dishwasher. Why not just throw it into the bathtub or swimming pool or, what the heck, the closest river. Nonsense. Wood will respond and not in a way that you will be happy with. I'd stake my 25 years of professional furniture finishing on it.

Rome aka Cabinetman.

Rome,

After stripping / sanding the old stocks. The exposed wood is a greyish color with black streaks. I would like the finished stock to be close to the same color as Greg's stock. Do I need to lighten up the wood? What is the easiest way? Or will a light colored stain such as Minwax Natural, get me a lighter finish?

Rome,

After stripping / sanding the old stocks. The exposed wood is a greyish color with black streaks. I would like the finished stock to be close to the same color as Greg's stock. Do I need to lighten up the wood? What is the easiest way? Or will a light colored stain such as Minwax Natural, get me a lighter finish?

If you want to lighten up the wood, you can either.

A: aggressively sand the wood

B: wash with oxalic acid dissolved in hot water

C: wood bleach

If you want to lighten up the wood, you can either.

A: aggressively sand the wood

B: wash with oxalic acid dissolved in hot water

C: wood bleach

Boxer is pretty much correct.

I shy away from suggesting sanding because too many fellas will sand for profile, not finish. When I sand, it's just to clear the initial finish surface. Now, if your stock is a grey color due to caustic cleaners, chances are that it's just the 1/64th thick surface that is grey. If you were to sand that away, chances are good you'd find a more virgin surface. However, then you end up ruining cartouches or other feature.

So, to lighten the surface you can use Boxer's "B" or "C" suggestion. This is for more advanced finishers.

You can bleach with a number of items but they can be very unpredictable and bothersome. Even the 5% solution of Clorox will work but, again, unpredictably. If you want the stock to be back to 'normal', I would recommend that you go to your local home store and find the Kleanstrip brand wood bleaching kit. IT contains two water-clear, very inert looking vials. You mix equal amounts and then rag onto your wood a very wet coat. Here's the secret. You will see NO difference until you let that stock go overnight and dry completely. This is not an instant bleaching kit and, as so, it will be very gentle with the original pigments. I would recommend two applications. One on one night, dry, then another.

After that you will take a piece of 180 stearated paper (found in home stores anymore; it's dry lubricated sanding paper and is usually pink or orange or some of other color. It is NOT garnet paper which is the worst thing you can use) Using the paper you will oh-so-gently rub the surface only. Scrub too hard and you'll end up with grey wood again. Now you can do what you would with the stock. I never use anything by Minwax. It's not really a good material to color with. Rather I recommend using "Behlen" products. You can google them and find their "15 minute stain" which is nothing BUT stain, no oil or other finish unlike Minwax which is nothing more than a little dye with some thinned tung oil. That seals the surface after one coat. The Behlen product is strictly color only, allows you to adjust the depth of color you're looking for by doubling or removing coats, and then you seal with your tung or BLO. I use the commercial variant of the same stuff in my shop.

Sorry for the long answer. Actually this is a short answer. You can find a bunch of this information at another site I moderated for many years.

http://parallaxscurioandrelicfirear...stock-cleaning/CR-stock-cleaning#.VVDfuvlVhBc

There we have a strict rule that defines restoration from repair. Each rifle we own has a history that we want to preserve. The stickies at the top of that forum are chock full of information that I won't have to retype.

Rome

dcmdon

NES Member

Run them through your dishwasher when your wife isn't home. Works great.

The dishwasher thing has worked great for me.

I don't run a full cycle. I set it for a full cycle and once it is up to temp, check on the stock every 10 minutes or so.

It has worked miracles on 3 field and rack grade CMP M1 Carbines I've putchased.

I used to work part time nights at a furniture store and they had an old timer that did all the repairs. I saw him pull dents with an iron and some sort of soaked cloth. His work was amazing and he never used filler. He would work the wood until it was actually a little raised and then sand it to match the surrounding area, then refinish. When he got done you would never find the repair.

I know that after 15+ years on line I'm not going to convince everyone but I do try to educate my friends about handling wood. Like most things we tend, today, to want a "finish in a can". Pop the lid and brush on a perfect finish. It can't happen. It's a marketing ploy. Same goes with prepping the wood. Like I've said many times before because you were successful with a hot-dishwasher bath does not make that the ideal way to handle and old stock. Quite the contrary that's the prefect way to destroy one. If yours survived that assault doesn't mean that should be the process which everyone else should follow. It's destructive, it's unpredictable, and it can and will damage that 70 year old piece of walnut to be sure given just a chance.

If I can contribute three truths to the field of firearms collecting it would be to eradicate the use of dishwashers and stopping the use of oven cleaners or solvent baths. I will die a happy camper feeling that I've contributed to the preservation of our beloved firearms. In the annals of woodworking.......chose any discipline over any time period and you will not find mention of bathing wood in water to accomplish anything other than to swell it to lock in a joint. No finishing technique in the world suggests that. Hell, here's a flyer from our own government about just that: http://www.nps.gov/museum/publications/conserveogram/07-07.pdf

Please don't do it.

Rome

www.romanpolaski.com

If I can contribute three truths to the field of firearms collecting it would be to eradicate the use of dishwashers and stopping the use of oven cleaners or solvent baths. I will die a happy camper feeling that I've contributed to the preservation of our beloved firearms. In the annals of woodworking.......chose any discipline over any time period and you will not find mention of bathing wood in water to accomplish anything other than to swell it to lock in a joint. No finishing technique in the world suggests that. Hell, here's a flyer from our own government about just that: http://www.nps.gov/museum/publications/conserveogram/07-07.pdf

Please don't do it.

Rome

www.romanpolaski.com

Boxer is pretty much correct.

I shy away from suggesting sanding because too many fellas will sand for profile, not finish. When I sand, it's just to clear the initial finish surface. Now, if your stock is a grey color due to caustic cleaners, chances are that it's just the 1/64th thick surface that is grey. If you were to sand that away, chances are good you'd find a more virgin surface. However, then you end up ruining cartouches or other feature.

So, to lighten the surface you can use Boxer's "B" or "C" suggestion. This is for more advanced finishers.

You can bleach with a number of items but they can be very unpredictable and bothersome. Even the 5% solution of Clorox will work but, again, unpredictably. If you want the stock to be back to 'normal', I would recommend that you go to your local home store and find the Kleanstrip brand wood bleaching kit. IT contains two water-clear, very inert looking vials. You mix equal amounts and then rag onto your wood a very wet coat. Here's the secret. You will see NO difference until you let that stock go overnight and dry completely. This is not an instant bleaching kit and, as so, it will be very gentle with the original pigments. I would recommend two applications. One on one night, dry, then another.

After that you will take a piece of 180 stearated paper (found in home stores anymore; it's dry lubricated sanding paper and is usually pink or orange or some of other color. It is NOT garnet paper which is the worst thing you can use) Using the paper you will oh-so-gently rub the surface only. Scrub too hard and you'll end up with grey wood again. Now you can do what you would with the stock. I never use anything by Minwax. It's not really a good material to color with. Rather I recommend using "Behlen" products. You can google them and find their "15 minute stain" which is nothing BUT stain, no oil or other finish unlike Minwax which is nothing more than a little dye with some thinned tung oil. That seals the surface after one coat. The Behlen product is strictly color only, allows you to adjust the depth of color you're looking for by doubling or removing coats, and then you seal with your tung or BLO. I use the commercial variant of the same stuff in my shop.

Sorry for the long answer. Actually this is a short answer. You can find a bunch of this information at another site I moderated for many years.

http://parallaxscurioandrelicfirear...stock-cleaning/CR-stock-cleaning#.VVDfuvlVhBc

There we have a strict rule that defines restoration from repair. Each rifle we own has a history that we want to preserve. The stickies at the top of that forum are chock full of information that I won't have to retype.

Rome

The wood bleaching sounds like too much work. Application, then neutralizing with white vinegar rinse and repeat. With regards to sanding. How much / long do I have to sand before I can conclude that no amount of sanding is going to reveal a lighter grain?

First of all DON'T neutralize the bleaching. Let it dry on its own and let the bleach to it's work for you. If you were to sand, you'd be sanding down about 1/64 all the way through. Caustic chemical only affect the visible part of the stock. IT doesn't penetrate much at all but it will change the color of wood. But I wouldn't sand. I would just wet a rag in the bleach, hang the stock, and soak the exterior well and then let it hang overnight. In the morning you'll see an initial change.

Rome

Rome

First of all DON'T neutralize the bleaching. Let it dry on its own and let the bleach to it's work for you. If you were to sand, you'd be sanding down about 1/64 all the way through. Caustic chemical only affect the visible part of the stock. IT doesn't penetrate much at all but it will change the color of wood. But I wouldn't sand. I would just wet a rag in the bleach, hang the stock, and soak the exterior well and then let it hang overnight. In the morning you'll see an initial change.

Rome

Rome last question. Should I use a wood conditioner before applying stain? I refinished several other stocks to my liking and have never used it. However I've never had a stock that has required this much prep work.

In the trades, a "wood conditioner" would be called a "spit coat". What happens is that a stock (or any piece of furniture) has some spots were the grain in open or erupts on a flat surface. Places like the wrist of the stock have cutouts so the end grain is exposed. These grains are like open straws as opposed to the sides of the stock that are straight grained. The open straws will absorb finish more readily and become dark. We call it "blotch". You see it all the time on pine boards and maple for that matter. By "conditioning" the wood you are applying a thin coat of finish (spit coat) that will plug the end grain and they cannot absorb excess stain and get blotchy. You can use literally anything for a spit coat. I'll use a very thin coat of sprayed lacquer or shellac; just enough to put something down. You let it dry and then gently sand just the surface to smooth it out. Then you apply your stain and it’ll go on evenly.

Hope that explains it. I truly love sharing what I know about my work with anyone willing to listen. Finishing is not magic but, as with most disciplines there is a learning and experimentation curve. What you’ll find out quickly is that there is nothing in HD or Lowes that will help you. I try to help the fellas go on the right path. Experimentation is critical but knowing what you're doing is also critical. Finishing is not just popping open a can. Ever see a finish on a piece of wood that looks translucent and three dimensional? That type of finish is well within the grasp of pretty much anyone willing to learn and understand the steps to get there. Working on our historic wood stock requires a respect for what those stocks have seen and not trying to make the new again but restoring them so they are functional for now and into the future.

Rome

Hope that explains it. I truly love sharing what I know about my work with anyone willing to listen. Finishing is not magic but, as with most disciplines there is a learning and experimentation curve. What you’ll find out quickly is that there is nothing in HD or Lowes that will help you. I try to help the fellas go on the right path. Experimentation is critical but knowing what you're doing is also critical. Finishing is not just popping open a can. Ever see a finish on a piece of wood that looks translucent and three dimensional? That type of finish is well within the grasp of pretty much anyone willing to learn and understand the steps to get there. Working on our historic wood stock requires a respect for what those stocks have seen and not trying to make the new again but restoring them so they are functional for now and into the future.

Rome

Share:

Similar threads

- Replies

- 60

- Views

- 970

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)