Ok so this thread grabs my interest as I have some more parts that magically appeared and was thinking of 9mm.

I'm really curious though of few things.

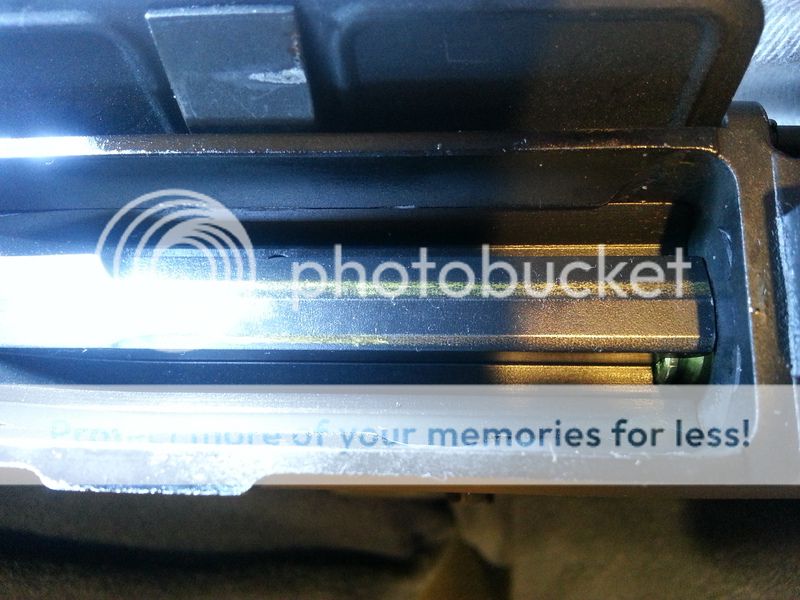

Is this a head space issue? Head space on a straight cased pistol rounds is from case mouth to face of the bolt correct?

Trying to word this correctly.

Is the headspace problem or just the feed ramp cut to deeply?

I'm also wondering , other than the easy of manufacturing. Why is the feed ramp cut around the entire circumference of the barrel?

I look at the pictures and see that using a headspace gauge and get a go on the check would not help with the deep feed ramp issue.

Besides of east of manufacturing having the feed ramp all the way around (simple op on a lathe).

Having it all the way around directs it to the center better.

Feeding from a single stack mag you could get away with it being mainly on the bottom and little on the sides. Think a 1911 barrel. Having the feed ramp on top will force rounds that started to feed high back down to the center . A 1911 barrel hood section dose the same thing .

On the ar45 I made and my ak 45 I made I found some times the rounds would pop up high some times and adding a chamfer on the top help keep the bullet from just jamming .

For the ar it's more of a problem with the bolt face . You need the mag mounted high, since the section of the bolt that strips the round doesn't stick down that far .most pistol cal mags the top round angles up. A stang (m16/m4/ar15 mag ect) the rounds sit flat at the top and the feed Ramps push them up and into the chamber .

On my ak45 since the akm bolt face stripper sections(I don't know what to call it) hangs lower I was able to mount the mags lower then my ar45 build. This makes it less likely to hit the top of the chamber but some time the way the round pops out it hit so I added the chamfer in top.

From the few scratch builds I have done feeding is a freaking black art.

Rule of thumb on pistol rounds you should have , .100 or less unsupported case. I basically copied a few barrels I had around. It comes down to the caliber and what the case can handle . Higher pressure rounds you need to have it chambered deeper then a lower pressure round.