I searched here for some info and didn't find much.

Since I was successful, I thought I'd post a tutorial if someone was thinking about it.

Here's the finished product

Here's what it was before, a nice gun with good case coloring, but somebody tried to cold blue the barrel, I think...who knows?

I removed the original bluing and the cold bluing with Barkeeper's Friend, and then polished with 220 and 320 grit emery paper lubricated with oil. Polished only lengthwise and was very careful around muzzle and breech so as to not round corners or remove decorative engraving.

Made a scalding tank out of PVC. Don't cut from the end like I did or the ends won't glue on - don't ask me how I know! Note picture further down for how the tank should look.

Degreased the barrel with diswashing liquid and hot water. Treated the barrel with a thin layer of Laurel Mountain Barrel Brown and Degreaser on a cotton swab in long smooth motions down the barrel. Then hang to rust in the bathroom with humidifer and space heater - got to 85F and 75% humidity

Rusted for 6 hours

Scalding with distilled water. This changes the fine red rust to a very fine black rust

Removed from water and air dried, the rust is a kind of fine velvet like deposit

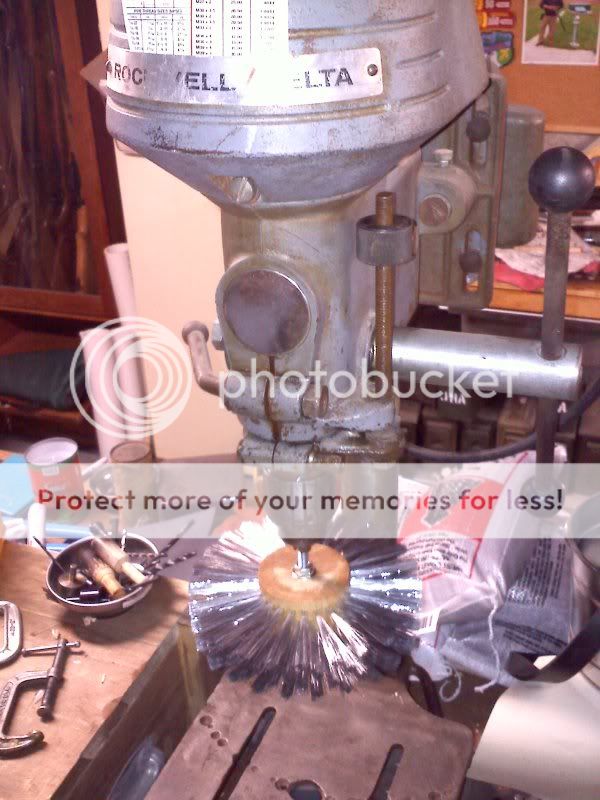

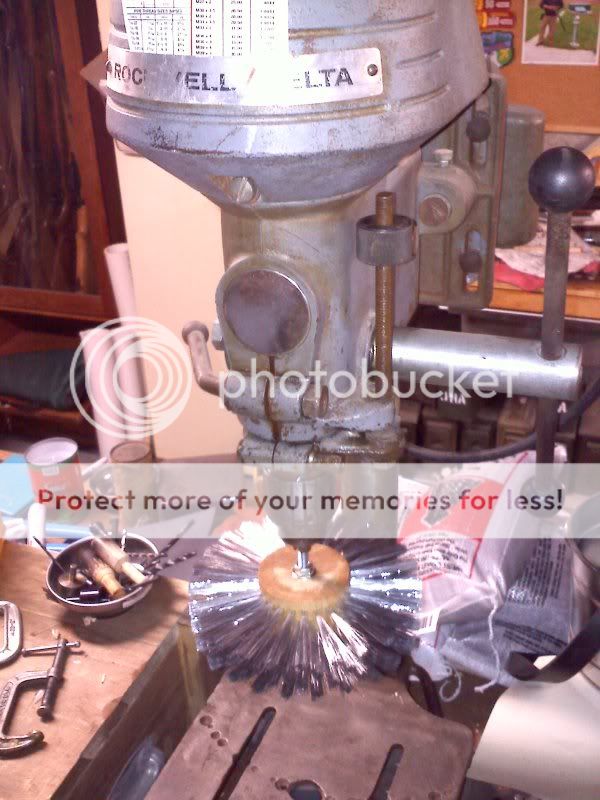

Carding wheel, a very fine wire brush which removes the rust but won't scratch - essential item (Brownells)

Carded and ready for another treatment

After three treatments

Done, four treatments, total

Done, barrel oiled

Costs:

Laurel Mountain Barrel Brown $13

Carding Wheel $20

Distilled Water (4 gals) $5

PVC and drain barb plus 1/4" NPT tap I didn't have $30

Emery paper (had it, but used about $1.00 worth)

Since I was successful, I thought I'd post a tutorial if someone was thinking about it.

Here's the finished product

Here's what it was before, a nice gun with good case coloring, but somebody tried to cold blue the barrel, I think...who knows?

I removed the original bluing and the cold bluing with Barkeeper's Friend, and then polished with 220 and 320 grit emery paper lubricated with oil. Polished only lengthwise and was very careful around muzzle and breech so as to not round corners or remove decorative engraving.

Made a scalding tank out of PVC. Don't cut from the end like I did or the ends won't glue on - don't ask me how I know! Note picture further down for how the tank should look.

Degreased the barrel with diswashing liquid and hot water. Treated the barrel with a thin layer of Laurel Mountain Barrel Brown and Degreaser on a cotton swab in long smooth motions down the barrel. Then hang to rust in the bathroom with humidifer and space heater - got to 85F and 75% humidity

Rusted for 6 hours

Scalding with distilled water. This changes the fine red rust to a very fine black rust

Removed from water and air dried, the rust is a kind of fine velvet like deposit

Carding wheel, a very fine wire brush which removes the rust but won't scratch - essential item (Brownells)

Carded and ready for another treatment

After three treatments

Done, four treatments, total

Done, barrel oiled

Costs:

Laurel Mountain Barrel Brown $13

Carding Wheel $20

Distilled Water (4 gals) $5

PVC and drain barb plus 1/4" NPT tap I didn't have $30

Emery paper (had it, but used about $1.00 worth)

Last edited:

![Thumbs Up [thumbsup] [thumbsup]](/xen/styles/default/xenforo/smilies.vb/044.gif)

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif) this seems to be a hell of a good outcome.

this seems to be a hell of a good outcome.