Ok, never thought i'd be bringing this topic up again on the net but here goes. There has been years of debate over finishes on Swiss and Finn rifles. A book by Terence Lapin on Mosin Nagants goes into some explanation of the finish of Finn captured Mosin Nagants. Now most people say this is just theory and theories are sometimes proven wrong, but for me and the results i've seen on my own rifles, this works best.

Rumor has it that the Finns used Potasium Permanganate to stain their stocks. This "dye" is available through some online retailers. I got mine through a native american craft site that sells it for coloring bone and wood. Its also available through some hardware stores. I thinks its used to treat hard water, and thats its main purpose. My first attempt at using this stuff came from my first Finn M39 rifle that had a well worn spot on the handguard. It was light colored and had little protective finish on it and I wanted it to be uniform so I started researching. After mixing some up I tried it out and was pleased with the results. Adding the 1/3 mix as a finish coat for protectant made the whole rifle look like it was meant to and everything blended in well.

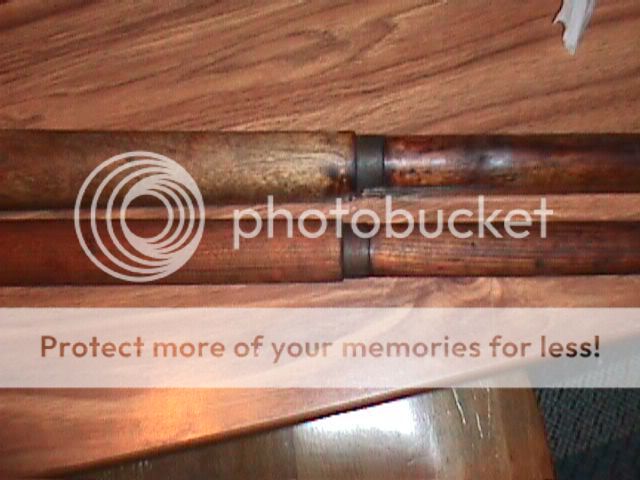

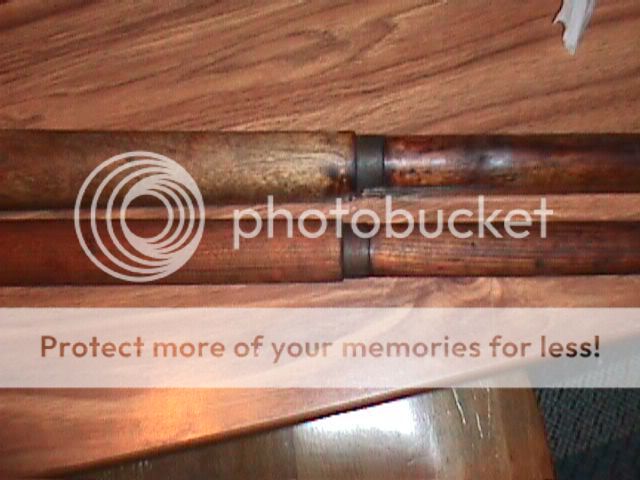

This picture shows the top and bottom handguard of the stock. You can see the diference in wood color from the light untreated wood on top to the left, and the hand guard treated with Potasium Permanganate on the bottom.

The handguard on the bottom only has the left side treated. The color you see on the right of it is original. I'd say its a spot on match.

Now the 1/3 mix that is rumored to be used for protectant consists of BLO (Boiled Linseed Oil), Turpentine, and Bees Wax. 1/3 meaning equal parts of each ingredient be it 3 ounces of each, or a pint, however much you want to mix up. I used bees wax pellets found at a craft store since they are easier to melt. To make it you have to first heat the bees wax carefully in an old pot. I used a hot plate for this and did it downstairs in my cellar on a concrete floor with fire extinguisher nearby since it is dangerous. Most folks will choose to do this outside for 2 reasons... fumes, and possibility of fire if you spill it while mixing it. Once the bees wax comes up to a warm temperature it will start to melt and turn to liquid. Then you add the BLO and continue heating it because the wax will start to thicken up again once the BLO is added. When its thin again you can take it off the heat and add the turpentine which will bond it all together. Constant stiring is needed during the whole procedure to keep things well mixed. Some people use a double boiler method with an old coffee can in a pot of water. This works well because you can cap it and store it but it takes longer to bring the contents up to temp to melt. No matter what method you use, just be sure to mix it well once its finished and let it sit to solidify. If you're impatient like me you can stick it in the freezer and use it an hour later.![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)

Once it becomes a paste wax, simply apply it to the stock by rubbing it in. After I coat a stock, i'll let it sit for a few minutes, then buff it down with a rag. It takes some elbow grease and effort to buff it down to a smooth tack free finish, but the results are worth it. The friction generated by hand buffing helps melt the mix into the stock. This adds both a water proof protectant and in my opinion closely duplicates the finish found on Finn Mosin Nagants.

Now after all that typing, heres a link for info on the shellac used in Swiss rumored finishes.

http://www.gunboards.com/forums/topic.asp?TOPIC_ID=133016

I have no experience in refinishing a Swiss stock, but trust the info found there.

Rumor has it that the Finns used Potasium Permanganate to stain their stocks. This "dye" is available through some online retailers. I got mine through a native american craft site that sells it for coloring bone and wood. Its also available through some hardware stores. I thinks its used to treat hard water, and thats its main purpose. My first attempt at using this stuff came from my first Finn M39 rifle that had a well worn spot on the handguard. It was light colored and had little protective finish on it and I wanted it to be uniform so I started researching. After mixing some up I tried it out and was pleased with the results. Adding the 1/3 mix as a finish coat for protectant made the whole rifle look like it was meant to and everything blended in well.

This picture shows the top and bottom handguard of the stock. You can see the diference in wood color from the light untreated wood on top to the left, and the hand guard treated with Potasium Permanganate on the bottom.

The handguard on the bottom only has the left side treated. The color you see on the right of it is original. I'd say its a spot on match.

Now the 1/3 mix that is rumored to be used for protectant consists of BLO (Boiled Linseed Oil), Turpentine, and Bees Wax. 1/3 meaning equal parts of each ingredient be it 3 ounces of each, or a pint, however much you want to mix up. I used bees wax pellets found at a craft store since they are easier to melt. To make it you have to first heat the bees wax carefully in an old pot. I used a hot plate for this and did it downstairs in my cellar on a concrete floor with fire extinguisher nearby since it is dangerous. Most folks will choose to do this outside for 2 reasons... fumes, and possibility of fire if you spill it while mixing it. Once the bees wax comes up to a warm temperature it will start to melt and turn to liquid. Then you add the BLO and continue heating it because the wax will start to thicken up again once the BLO is added. When its thin again you can take it off the heat and add the turpentine which will bond it all together. Constant stiring is needed during the whole procedure to keep things well mixed. Some people use a double boiler method with an old coffee can in a pot of water. This works well because you can cap it and store it but it takes longer to bring the contents up to temp to melt. No matter what method you use, just be sure to mix it well once its finished and let it sit to solidify. If you're impatient like me you can stick it in the freezer and use it an hour later.

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)

Once it becomes a paste wax, simply apply it to the stock by rubbing it in. After I coat a stock, i'll let it sit for a few minutes, then buff it down with a rag. It takes some elbow grease and effort to buff it down to a smooth tack free finish, but the results are worth it. The friction generated by hand buffing helps melt the mix into the stock. This adds both a water proof protectant and in my opinion closely duplicates the finish found on Finn Mosin Nagants.

Now after all that typing, heres a link for info on the shellac used in Swiss rumored finishes.

http://www.gunboards.com/forums/topic.asp?TOPIC_ID=133016

I have no experience in refinishing a Swiss stock, but trust the info found there.