-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Resleeving a barrel

- Thread starter MFSP101

- Start date

It’s fairly common for break action shotguns. Sleeves for all sorts of calibers.

You can technically do it with any barrel where there’s enough room for a safe chamber in the new caliber. But for a pistol, you’d likely only be able to sleeve for 22lr or something. And then what are you doing for magazines and feeding into an offset chamber?

You can technically do it with any barrel where there’s enough room for a safe chamber in the new caliber. But for a pistol, you’d likely only be able to sleeve for 22lr or something. And then what are you doing for magazines and feeding into an offset chamber?

I’ve been playing around with an idea. Can a barrel be resleeved for another caliber if there isn’t a conversion kit for it?

I was thinking about 22tcm9r in a LC9S.

Let the bashings begin.

![Cheers [cheers] [cheers]](/xen/styles/default/xenforo/smilies.vb/018.gif)

They have 22tcm9r conversions for Glocks. It’s a necked down 9mm. So I thought why couldn’t it be done for the LC9S. Obviously not a lot of call for it but I have the ability to do it if I can get enough info to do it right.It’s fairly common for break action shotguns. Sleeves for all sorts of calibers.

You can technically do it with any barrel where there’s enough room for a safe chamber in the new caliber. But for a pistol, you’d likely only be able to sleeve for 22lr or something. And then what are you doing for magazines and feeding into an offset chamber?

They have 22tcm9r conversions for Glocks. It’s a necked down 9mm. So I thought why couldn’t it be done for the LC9S. Obviously not a lot of call for it but I have the ability to do it if I can get enough info to do it right.

For that round, you’re going to need a whole new chamber. It has a necked section that would be unsupported by a 9mm chamber.

You’re going to need to be looking for a 22tcm9r barrel for your LC9S. Not a sleeve.

Maybe you can find a custom barrel maker to do one for you. But your much cheaper option is probably to buy a Glock and get the conversion barrel for it.

cheaper, simpler but not nearly as entertaining.But your much cheaper option is probably to buy a Glock and get the conversion barrel for it.

a crazy sleeve in thing was some soviet contraption to shoot a 7.62 from the 12ga shotgun. there were the times...

cheaper, simpler but not nearly as entertaining.

a crazy sleeve in thing was some soviet contraption to shoot a 7.62 from the 12ga shotgun. there were the times...

7.62x39 Shotgun Adapters - Shotgun Adapters - https://chaszel.com

7.62x39 Rifle Shotgun Adapters Allows a 12Ga Shotgun to use 7.62x39 ammo. For 3″ or 2 3/4″ Chambers Compatible with Break Action Shotguns.

chaszel.com

chaszel.com

KMM696

NES Member

If anyone is going to have an appropriate barrel liner for that project, it'd be Redman's Rifling. They sell the more commonly used liners through Brownells, but I don't think this would qualify as common.

The other option is buy a short piece of blank barrel, turn that down to liner appropriate dimensions, install and chamber. Either way, feeding could get a little weird. Not familiar enough with that pistol to guess how that's going to work.

The other option is buy a short piece of blank barrel, turn that down to liner appropriate dimensions, install and chamber. Either way, feeding could get a little weird. Not familiar enough with that pistol to guess how that's going to work.

KMM696

NES Member

It occurred to me that a rifle smith who makes custom barrels probably throws away cut off sections of .223 barrel that are just what you would need, and is just the guy to turn it down to the correct OD.

I was looking at used barrels on eBay. I can do the turning and boring. I’ve seen one way to do it. Thanks for the input. I believe we have a machinist that has an FFL in town also that might do that kind of work.It occurred to me that a rifle smith who makes custom barrels probably throws away cut off sections of .223 barrel that are just what you would need, and is just the guy to turn it down to the correct OD.

KMM696

NES Member

I've been shooting 22TCM for a bit, but it's much easier in a Contender.  Am I remembering correctly that the 22TCM9r has a short bullet to fit in 9mm magazines? In a 13" Contender barrel it's in the neighborhood of 22 Hornet. I have had issues with the Armscor brass splitting, even on first firing. My suspicion is it isn't annealed well, which isn't surprising considering how short the case is.

Am I remembering correctly that the 22TCM9r has a short bullet to fit in 9mm magazines? In a 13" Contender barrel it's in the neighborhood of 22 Hornet. I have had issues with the Armscor brass splitting, even on first firing. My suspicion is it isn't annealed well, which isn't surprising considering how short the case is.

The bullet is a 39 grain. I’m not sure if it’s shorter or just deeper in the cartridge. It does seem to be flatter at the tip. Yea it is made to the length of a 9mmI've been shooting 22TCM for a bit, but it's much easier in a Contender.Am I remembering correctly that the 22TCM9r has a short bullet to fit in 9mm magazines? In a 13" Contender barrel it's in the neighborhood of 22 Hornet. I have had issues with the Armscor brass splitting, even on first firing. My suspicion is it isn't annealed well, which isn't surprising considering how short the case is.

do you have a source of the chamber reamer ? Are you going to make it a friction fit and "glue" it in?I’ve been playing around with an idea. Can a barrel be resleeved for another caliber if there isn’t a conversion kit for it?

I was thinking about 22tcm9r in a LC9S.

Let the bashings begin.

Chaszel barrel adapters might be helpful.

I think the issue is where do you make the "chamber. Are you going to sleeve the 9mm barrel back into the chamber where the neck needs to be machined ? Then re cut the chamber for the tmc22?

I looked at Chaszel. The problem with that one is it is .370 OD. They say you can JB weld in place. But I wouldn’t be able to get the chamber right I think. There is one place I found for the reamer. Little pricey but it’s a one off project.do you have a source of the chamber reamer ? Are you going to make it a friction fit and "glue" it in?

Chaszel barrel adapters might be helpful.

I think the issue is where do you make the "chamber. Are you going to sleeve the 9mm barrel back into the chamber where the neck needs to be machined ? Then re cut the chamber for the tmc22?

I bought a damage Stevens rifle barrel. And a Lc9s barrel and spring. Once I get it I’ll start looking at what to do. Boring the barrel out make a sleeve with a step on it to seat deep in the barrel and then bore the chamber. Probably Tig weld the sleeve at the muzzle end of the barrel.

At least that’s the plan so far.

.370 sounds good? Only have to machine down to .355 ish for a nice tight fit and ise epoxy or that super loctite that holds bearing races in place. You could leave the chamber end at .370 it would take up a lot of space for the shoulder and neck area when you cut it.I looked at Chaszel. The problem with that one is it is .370 OD. They say you can JB weld in place. But I wouldn’t be able to get the chamber right I think. There is one place I found for the reamer. Little pricey but it’s a one off project.

I bought a damage Stevens rifle barrel. And a Lc9s barrel and spring. Once I get it I’ll start looking at what to do. Boring the barrel out make a sleeve with a step on it to seat deep in the barrel and then bore the chamber. Probably Tig weld the sleeve at the muzzle end of the barrel.

At least that’s the plan so far.

You could probably rent a chamber cutter and finish reamer from 4-D rental.

If I was going to attempt I would probably source another barrel and give it a go.

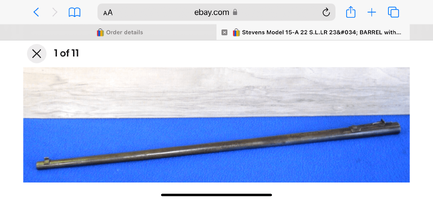

So here are some pics. Got the donor barrel. Started turning it down. To see how it turns on a lathe. So far so good. Will finish dimension it once I research a little more. Got the other LC9S donor barrel to sleeve. Waiting on some ammo. To take some measurements. Still thinking about buying or renting the reamer. Fun project so far.

Attachments

KMM696

NES Member

22 TCM - 4D Reamer Rentals

I haven't used them before, but at least they exist in the rental market.

I haven't used them before, but at least they exist in the rental market.

There’s a guy that did it with sig sauer. He has a video. I’m basically following his idea and adapting it to the LC9S barrel. After measuring that one and accommodating it.Yeah, I've been thinking about how to make a liner work with the existing barrel, and don't have anything solid. I'm sure it could work, just not sure how exactly.

KMM696

NES Member

I'm not sure if epoxy alone can hold the liner against recoil. It very well may I just don't know. Seems one option would be to drill the entire barrel including the chamber to over chamber ID, match the liner to that diameter and epoxy,then cut the chamber into the barrel liner entirely.

The other option I thought of was to do the same thing, except with a step in the liner at the muzzle end of the barrel that would rest against the existing barrels muzzle and give a mechanical lug against recoil.

Or drill from the muzzle end of the existing barrel and cut just into the chamber, leaving an internal step for the liner to rest against, epoxy it in place and then cut the chamber. Seems like that would be the most difficult to ensure drilling to exactly the right depth. On the other hand if it went wrong, could still try either of the first two methods.

I just have no idea which would be best.

The other option I thought of was to do the same thing, except with a step in the liner at the muzzle end of the barrel that would rest against the existing barrels muzzle and give a mechanical lug against recoil.

Or drill from the muzzle end of the existing barrel and cut just into the chamber, leaving an internal step for the liner to rest against, epoxy it in place and then cut the chamber. Seems like that would be the most difficult to ensure drilling to exactly the right depth. On the other hand if it went wrong, could still try either of the first two methods.

I just have no idea which would be best.

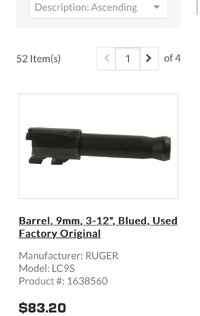

Yes. I already got a barrel and spring.This is the barrel correct?

View attachment 719735

Basically. The sleeve will be stepped. Then the chamber drilled into the new liner. Then the forces are all in the new liner.I also plan on getting the tolerances so I heat up the barrel, freeze the sleeve press together and that should hold the sleeve. And using loctite 660. To bond them togetogether.I'm not sure if epoxy alone can hold the liner against recoil. It very well may I just don't know. Seems one option would be to drill the entire barrel including the chamber to over chamber ID, match the liner to that diameter and epoxy,then cut the chamber into the barrel liner entirely.

The other option I thought of was to do the same thing, except with a step in the liner at the muzzle end of the barrel that would rest against the existing barrels muzzle and give a mechanical lug against recoil.

Or drill from the muzzle end of the existing barrel and cut just into the chamber, leaving an internal step for the liner to rest against, epoxy it in place and then cut the chamber. Seems like that would be the most difficult to ensure drilling to exactly the right depth. On the other hand if it went wrong, could still try either of the first two methods.

I just have no idea which would be best.

pretty much my thought , The recoil should drive the insert forward, no ? You could definitely give the muzzle end a bit of welding ? could over engineer it also and use a set screw somewhereBasically. The sleeve will be stepped. Then the chamber drilled into the new liner. Then the forces are all in the new liner.I also plan on getting the tolerances so I heat up the barrel, freeze the sleeve press together and that should hold the sleeve. And using loctite 660. To bond them togetogether.

Share: